- Product Details

- {{item.text}}

Quick Details

-

Model Number:

-

SL-50

-

Power:

-

0.59 kw

-

Material:

-

anti-corrosion Q235 carbon steel, High Temperature Resistant Paint

-

Weight (KG):

-

650 kg

-

After-sales Service Provided:

-

Commissioning

-

Application:

-

Waste

-

Color:

-

Customized

-

Raw material:

-

Waste Garbage

-

Name:

-

Waste incinerator

-

Capacity:

-

20-30kg/time (3-6 times/day)

-

Function:

-

Garbage Recycling

-

Product name:

-

Waste Decomposer

-

Certification:

-

CE ISO

Quick Details

-

Production Capacity:

-

Other

-

Place of Origin:

-

Henan, China

-

Brand Name:

-

Shuliy

-

Model Number:

-

SL-50

-

Power:

-

0.59 kw

-

Material:

-

anti-corrosion Q235 carbon steel, High Temperature Resistant Paint

-

Weight (KG):

-

650 kg

-

After-sales Service Provided:

-

Commissioning

-

Application:

-

Waste

-

Color:

-

Customized

-

Raw material:

-

Waste Garbage

-

Name:

-

Waste incinerator

-

Capacity:

-

20-30kg/time (3-6 times/day)

-

Function:

-

Garbage Recycling

-

Product name:

-

Waste Decomposer

-

Certification:

-

CE ISO

Shuliy smokeless waste oil toilet incinerator for poultry industrial waste to energy incinerator

Brief Introduction of waste incinerator

Incinerators,also called waste incinerator, waste incinerator,garbage incinerator,incinerator burner.It is environmentally friendly equipment.Incinerators adopt high temperature heating technology. Waste is burned in an incinerator.Harmful substances in waste are pyrolyzed at high temperatures and destroyed.It is suitable for the harmless treatment of waste gas, waste liquid, solid waste fuel, waste, domestic waste, and animal carcasses.

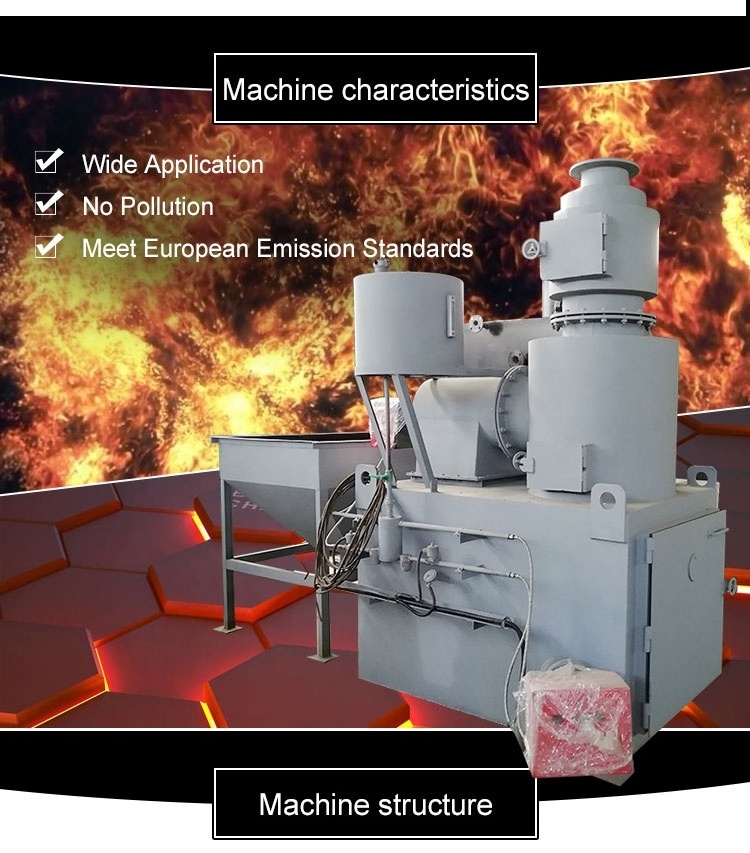

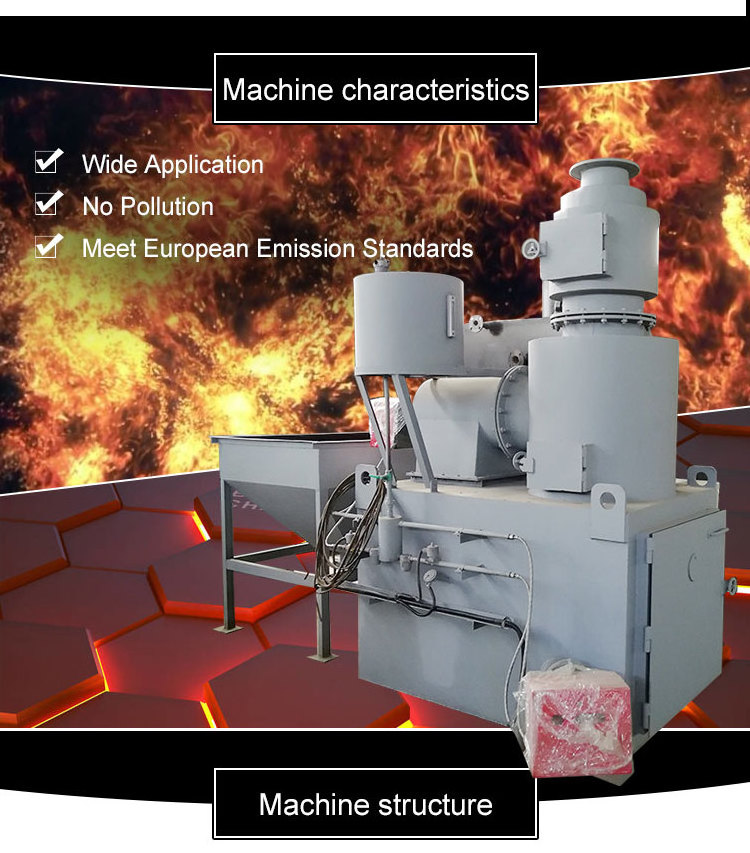

Feature of waste incinerator

1. Wide application. It can handle industrial waste, daily garbage, hospital waste, and waste rubber tires.

2. The combustion heat efficiency is high. The combustion heat efficiency is 80% or more, and even large moisture daily garbage can be handled.

3. Simple operation. It only takes one person to operate.

4. Long working life.The annual operation time is over 8000 hours,machine life over 10 years.

5. The dealed flue gas meets the European emission standards.

6. Fully enclosed operation, even for items that are easy to infect, can be deal without secondary pollution.

7. The combustion method is optional. Our burners are available in both fuel and gas, and customers can use different types as needed.

Application of waste incineraor

1. Industrial Waste : plastic PE, PU, rubber (tire),PET bottle, fibers, foam, cloth, resin, acrylic, leather, laminated board, urea powder, melon cloth, tape, paint, polymer, etc.

2, Waste: syringes, gloves, bags, gauze, blood vessels, organs and other infectious waste.

3, Domestic Garbage: cardboard, paper scraps, sawdust, leaves and so on.

4. Special Waste: waste oil, waste solvent, sludge, dust pool, iron paint, mold filter residue, etc.

Advantage of waste incinerator

1. The combustion room adopts refractory insulation material, which can effectively increase the temperature of the furnace, accelerate the ignition of the treatment object, and promote the burning of the smoke.

2. 90% of the residue after burning can be used as a greening fertilizer, and the 5% - 10% can be used to make bricks.

3. The harmful gases can be completely remove after being processed by the incinerators, and there is no pollution to the environment.

4. Exhaust gas has no black smoke, no unpleasant smell , no dust particles.

5. The combustor can be adjusted up and down by 25cm, which can cover the material more fully for different materials.It can save fuel and shorten the burning time.

6. Larger combustion room can avoid the dust particles from burning up.And accelerate the burning of materials at high temperatures.

7. When dealing with infectious dangerous waste, there will be no secondary pollution.

Parameter of waste incinerator

|

Model |

WFS-30 |

WFS-50 |

WFS-150 |

WFS-300 |

|

Burning Capacity |

20-30kg/time (3-6 times/day) |

30-50kg/time (3-6times/day) |

100-150kg/time (3-6times/day) |

200-300kg/time (3-6times/day) |

|

Incinerator Size (L*H*B) |

1.45*0.9*1.75 m |

1.8*1.15*3 m |

2*1.4*3.5 m |

2.2*1.4*3.8 m |

|

Imputing Mouth Width |

480*600 mm |

620*800 mm |

760*960 mm |

900*1100 mm |

|

Chimney External Diameter |

280 mm |

280 mm |

300 mm |

400 mm |

|

Draught Fan |

0.37kw |

0.37kw |

0.5kw |

1.1kw |

|

Combustion Improver Device |

0.11kw Oil consumption: 4-6kg/h |

0.11kw Oil consumption: 4-10kg/h |

0.11kw Oil consumption: 4-10kg/h |

0.22kw Oil consumption: 7-14kg/h |

|

Re-Burning Device |

0.11 kw Oil consumption 4-6 kg/h |

0.11kw Oil consumption: 4-10kg/h |

0.22kw Oil consumption: 7-14kg/h |

0.37kw Oil consumption: 10-20kg/h |

|

Voltage |

380v/220v |

380v/220v |

380v/220v |

380v/220v |

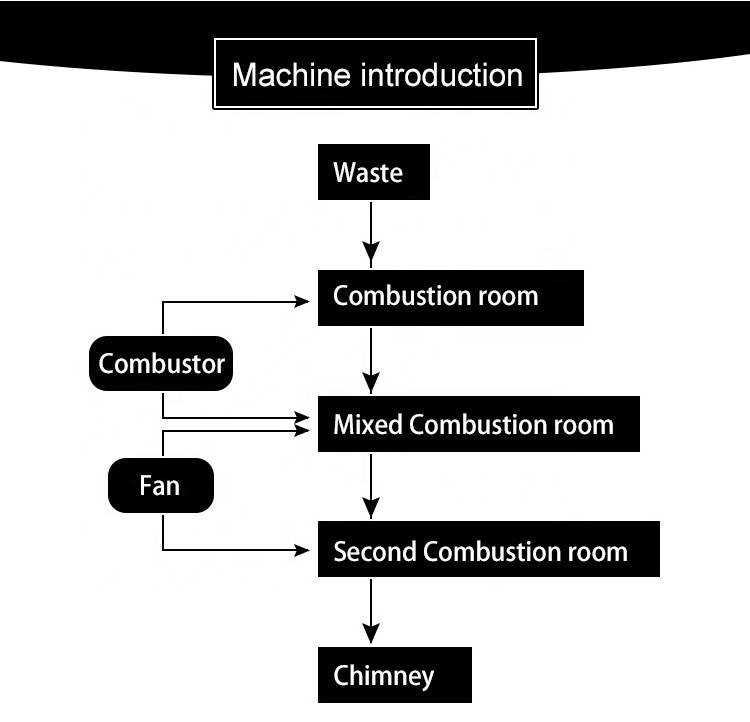

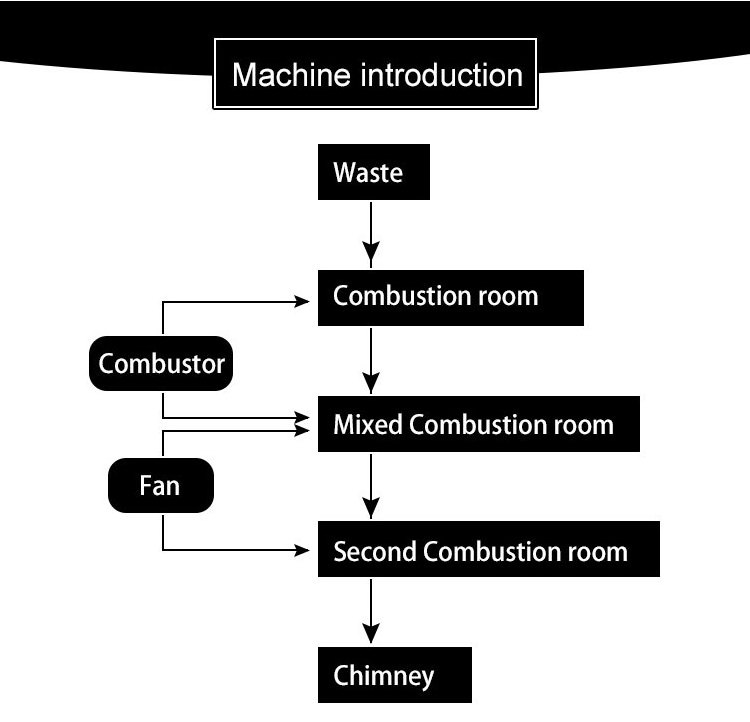

Work Principle of waste incinerator

The principle of incinerator :incineration and carbonization of material at high temperature.To achieve the purpose of disinfection.Without adding any fuel, the material is self-burning, the exhaust smoke is white smoke, no unpleasant smell.The waste is manually put into the main combustion room of the incinerator body, and the first temperature combustion is started by automatic temperature control, which is fully oxidized, pyrolyzed and burned .The flue gas by the incineration enters the second combustion room, and the unburned harmful material in the flue gas are further destroyed in the second combustion room.In order to completely break down the unburned materials and meet the emission requirements,the second combustion room is equipped with a combustor to assist. Combustion.A fan is arranged to ensure flue gas is in full contact with oxygen at a high temperature.The second combustion room removes the large particles of dust through the dust collector, so that the incineration efficiency and the destruction removal rate are over 99%.It can achieve the effect of smokeless, meet the national emission standard.Then it enters the chimney and is exhaust into the atmosphere. The ash produced after combustion is manually taken out.

The main purpose of incineration is to burn waste as much as possible, to make the incinerated materials harmless and minimize volume reduction.Reduce new pollutants and avoid secondary pollution. For large and medium-sized waste incineration plants, the three purposes of reducing waste, completely burning harmful substance in waste, and recycling heat from waste incineration can be achieved at the same time.The incinerator can handle solid waste,liquid waste and gas waste.Urban waste,industrial waste, and dangerous waste also can be dealt .The outer shell of the incinerator is made of steel, the inner wall is made of casting material with different characteristics.It can stand with high temperature of 1790 °C, and the middle is light refractory material, which can ensure enough combustion temperature inside, and keep the shell low temperature to avoid burns. The refractory material is whole cast , not easy to fall off and not easy to corrode.