- Product Details

- {{item.text}}

Quick Details

-

Voltage:

-

Customizable

-

Dimension(L*W*H):

-

Customizable

-

Weight:

-

10000 KG

-

Name:

-

Mineral Separator Flotation Machine

-

Installation:

-

Engineer Guide

-

Material:

-

Copper Gravity Separation Plant

-

The Machines classification:

-

Mining Equipment

-

Quality:

-

Advanced Technology

-

Function:

-

Stone crushing

-

Factory visit:

-

Welcomed Warmly

-

Usage:

-

industry use

-

Output size:

-

Customizable

-

Service:

-

24 Hours Online-service

Quick Details

-

Production Capacity:

-

Customizable

-

Place of Origin:

-

Jiangxi, China

-

Brand Name:

-

EASTMANT

-

Voltage:

-

Customizable

-

Dimension(L*W*H):

-

Customizable

-

Weight:

-

10000 KG

-

Name:

-

Mineral Separator Flotation Machine

-

Installation:

-

Engineer Guide

-

Material:

-

Copper Gravity Separation Plant

-

The Machines classification:

-

Mining Equipment

-

Quality:

-

Advanced Technology

-

Function:

-

Stone crushing

-

Factory visit:

-

Welcomed Warmly

-

Usage:

-

industry use

-

Output size:

-

Customizable

-

Service:

-

24 Hours Online-service

Product Description

Description

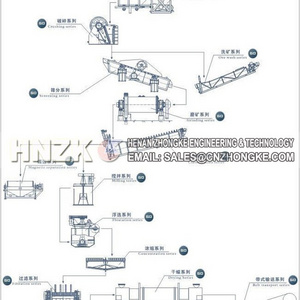

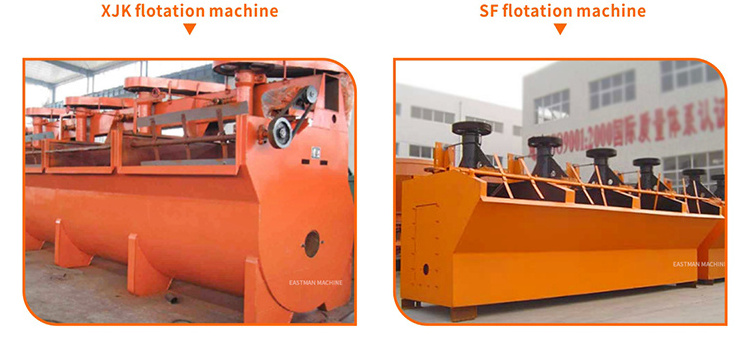

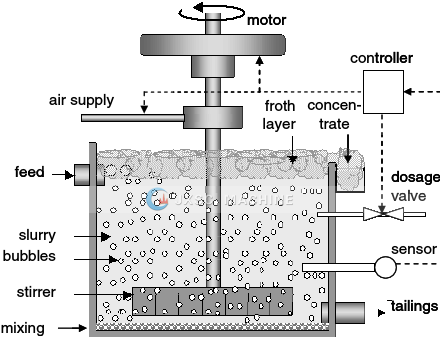

Flotation machine, in the ore dressing, mainly used for separating copper, zinc, lead, nickel, gold and other Non-ferrous metal, can also be used for Ferrous, non-metallic crude and selected.

After mixing the crushed ore with water and flotation reagent, the ore is mixed into a slurry tank, which is filled with air to form a large number of air bubbles. Some mineral particles which are not easily wet by water attach to the air bubbles and float to the surface of the pulp together with the air bubbles The formation of mineralized bubble layer, some easy to be water wet, hydrophilic mineral particles not attached to the bubble, and stay in the pulp, will contain specific minerals mineralized bubble discharge, so as to achieve the goal of mineral processing.

|

Model

|

Volume

|

Cell size

|

Impeller Dia.

|

Impeller speed

|

Capacity

|

Power

|

Singe cell weight

|

|

Unit

|

m3

|

mm

|

mm

|

r/min

|

m3/min

|

kw

|

kg

|

|

XJK-3A

|

0.35

|

700×700×700

|

300

|

483

|

0.18-0.4

|

2.2/0.55

|

430

|

|

XJK-4A

|

0.62

|

820×900×850

|

350

|

400

|

0.3-0.9

|

3/1.1

|

755

|

|

XJK-5A

|

1.1

|

1100×1100×1000

|

500

|

330

|

0.6-1.6

|

5.5/1.1

|

1416

|

|

XJK-6A

|

2.8

|

1750×1600×1100

|

600

|

280

|

1.5-3.5

|

11/1.1

|

2113

|

|

XJK-7A

|

5.8

|

2200×2200×1200

|

750

|

240

|

3–7

|

22/1.5

|

3400

|

|

SF-0.37

|

0.37

|

700×700×750

|

296

|

386

|

0.2-0.4

|

1.5/0.55

|

468

|

|

SF-0.7

|

0.7

|

820×900×950

|

350

|

400

|

0.3-0.9

|

3/1.1

|

805

|

|

SF-1.2

|

1.2

|

1100×1100×1100

|

450

|

312

|

0.6-1.2

|

5.5/1.1

|

1373

|

|

SF-2.8

|

2.8

|

1700×1600×1150

|

550

|

268

|

1.5-3.5

|

11/1.5

|

2138

|

|

SF-4

|

4

|

1850×2050×1200

|

650

|

220

|

2–4

|

15/1.5

|

2582

|

|

SF-8

|

8

|

2200×2900×1400

|

760

|

191

|

4–8

|

30/1.5

|

4129

|

|

SF-10

|

10

|

2200×2900×1700

|

760

|

191

|

5–10

|

30/1.5

|

4486

|

|

SF-16

|

16

|

2850×3800×1700

|

760

|

191

|

5–16

|

30×2/1.5

|

8320

|

|

SF-20

|

20

|

2850×3800×2000

|

760

|

191

|

5–20

|

30×2/1.5

|

9828

|

Product Structure

The metallurgist flotation mainly made up of slurry-supporting Trough, mixing device, aeration device, mineralized bubble discharging device and motor. Flotation cell is mainly used to select nonferrous metals such as copper, zinc, lead, nickel, gold, etc., and also be used for coarse selection and selection of black metal and nonmetal.

With the poor, fine, hybridized primary mineral resources and the increasing complexity of mineral processing technology, energy consumption and production costs, it is necessary to strengthen the research of flotation equipment in the following aspects. EASTMAN focus on the mineral equipment business since 1985, CE, SGS certified.

Products Details

Successful cases

China 100TPH Tin Processing Plant with Flotation Cell

We EASTMAN can design the whole processing line according to clients mineral info & requirement. In China, there are full of Tin, Tungsten ore. Many clients use flotation processing way for concentration.

Mexico 60TPH copper Processing Plant with Flotation Cell

Processing Ore: copper

Processing capacity: 60tph

Packing & Delivery

●Ways Of Packing

1.Small parts packed in the wooden cases.

2.Big parts packed by plastic membrane.

3.The whole big machine is loaded in the container.

● Shiping by sea/air freight

or any way the customer requires.

Company Introduction

1.Inquiry and consulting support.

2.Ore sample testing support.

3.View our Factory.

4.Design Flowchart.

1.Training how to instal the machine, training how to use the machine.

2.1 year warranty .

3.Engineers available to service machinery overseas.

FAQ

Questions customers asked

1.Q:How is the quality of your products?

A: Our products are manufactured strictly according to national and international standard, and we will take a test on every grinder before delivery.

2.Q:How about the Guaranteed?

A : All of our products are guaranteed for one year. If products quality is not consistent with the description as we described or the promise before you place order, we promise 100% refund.

3.Q:How about price?

A: For the complete same machine, we can promise our quality is the best when the price same as other competitors, and our price can be lowest when the quality at standard level.

4.Q:How about the service and payment terms?

A: We can accept T/T or other payment ways you request; 30% deposit, 70% balance before delivery, which is international trade practice; Finished product pictures will provide to customers before delivery.

1.Q:How is the quality of your products?

A: Our products are manufactured strictly according to national and international standard, and we will take a test on every grinder before delivery.

2.Q:How about the Guaranteed?

A : All of our products are guaranteed for one year. If products quality is not consistent with the description as we described or the promise before you place order, we promise 100% refund.

3.Q:How about price?

A: For the complete same machine, we can promise our quality is the best when the price same as other competitors, and our price can be lowest when the quality at standard level.

4.Q:How about the service and payment terms?

A: We can accept T/T or other payment ways you request; 30% deposit, 70% balance before delivery, which is international trade practice; Finished product pictures will provide to customers before delivery.

Hot Searches