- Product Details

- {{item.text}}

Quick Details

-

Voltage:

-

380V

-

Power:

-

200KW

-

Weight:

-

1000 KG

-

Dimension(L*W*H):

-

Depends on customer's need

-

Product name:

-

Mini dairy milk processing plant

-

After-sales Service Provided:

-

Engineers available to service machinery overseas

-

Material:

-

SUS304/316L

-

Control:

-

Automatic control

-

Energy consumption:

-

Low consumption

-

PLC control:

-

Siemens

-

Effeciency:

-

High effeciency

-

Processing Types:

-

Complete Processing Line

-

Heating:

-

Electric Heating

Quick Details

-

Marketing Type:

-

New Product 2024

-

Place of Origin:

-

Shanghai, China

-

Brand Name:

-

Beyond

-

Voltage:

-

380V

-

Power:

-

200KW

-

Weight:

-

1000 KG

-

Dimension(L*W*H):

-

Depends on customer's need

-

Product name:

-

Mini dairy milk processing plant

-

After-sales Service Provided:

-

Engineers available to service machinery overseas

-

Material:

-

SUS304/316L

-

Control:

-

Automatic control

-

Energy consumption:

-

Low consumption

-

PLC control:

-

Siemens

-

Effeciency:

-

High effeciency

-

Processing Types:

-

Complete Processing Line

-

Heating:

-

Electric Heating

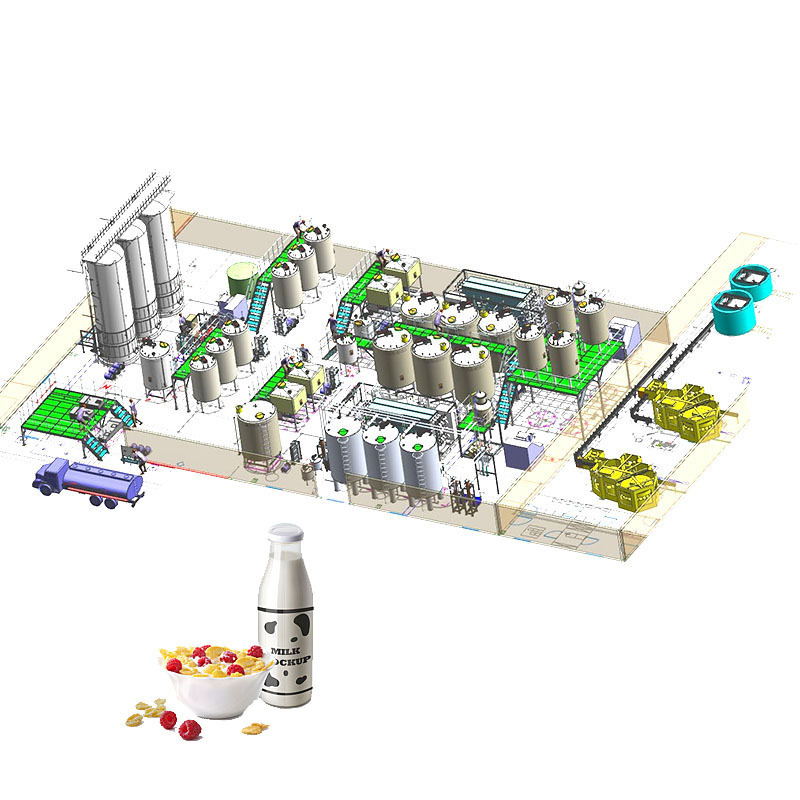

Hot sale mini turnkey dairy processing line / pasteurized milk/yogurt/cheese/butter

This small yogurt production line capacity is 2T/H, it can produce several types of flavored pasteurized milk products, i.e. whole milk, skimmed milk and standardized milk of various fat contents, meanwhile with options to produce yogurt, cheese, cream and butter etc.

This small yogurt production line raw milk can be fresh milk or powder milk or both , this small milk production line milk normally stored at low temperature about 4-5 degree, which can maintain the nutrition at maximum.

End product package of this small milk processing line can be plastic pouches, plastic cups, plastic bottles, glass bottles, roof top box etc . For this dairy production line according to different end product and package type, the production technology is differently designed but commonly include the following steps.

Equipment list sample of dairy processing line

| Equipment list of dairy processing line | |||

| No. | Name | Size | Main parameter |

| 1 | Milk reception and storage unit | ||

| 2 | Milk acceptor | 300L | SUS304 stainless steel, single layer, CIP spraying ball |

| 3 | Milk pump | 3T/H | SUS304, p ump lift 24m, h ard alloy mechanical seal, i nner shell mirror polished |

| 4 | Single piping filter | 3T/H | SUS304, single pipe, stainless steal filter element of 100 mesh |

| 5 | Milk storage tank | 1000L | SUS304, heat insulated, dimple pad jacket, vertical agitator, CIP spraying ball, breather valve, digital show thermometer, sampling point |

| 6 | Milk pump | 3T/H | SUS304, p ump lift 24m, h ard alloy mechanical seal, i nner shell mirror polished |

| 7 | Blending unit | ||

| 8 | Storage tank | 500L | SUS304, heat insulated, dimple pad jacket, vertical agitator, CIP spraying ball, breather valve, digital show thermometer, sampling point |

| 9 | Milk pump | 3T/H | SUS304, p ump lift 24m, h ard alloy mechanical seal, i nner shell mirror polished |

| 10 | Single piping filter | 3T/H | SUS304, single, stainless steal filter element of 100 mesh |

| 11 | Plate-type exchanger | 1.5T/H | SUS304, double pipes |

| 12 | High pressure homogenizer | 500L/H | 40MPa |

| 13 | Cream separtor unit | ||

| 14 | Milk separator | 500L/H | The content of dried skim milk ( % ) <0.03, the speed of rotator is 8000rpm |

| 15 | Buffer container | 100L | SUS304, with a cover, single layer |

| 16 | Buffer & cooling container | 100L | SUS304, with a cover, single layer |

| 17 | Milk pump | 3T/H | SUS304, with a cover, heat insulated, dimple pad jackets |

| 18 | Butter churner | 100L | SUS304 |

| 19 | Yogurt storage, ferment and filling unit | ||

| 20 | Temporary and ferment storage tanks | 500L | SUS304, heat insulated, dimple pad jacket, vertical agitator, CIP spraying ball, breather valve, digital show thermometer, sampling point |

| 21 | Milk pump | 3T/H | SUS304, p ump lift 24m, h ard alloy mechanical seal, i nner shell mirror polished |

| 22 | Rotor pump | 1T/H | SUS304, h ard alloy mechanical seal, adjustment speed by manual |

| 23 | Plastic pouch filling machine | ||

| 24 | Plastic cup-shaped filling machine | ||

| 25 | CIP system unit | ||

| 26 | Manual CIP system | 3×500L | SUS304, single clening circulation, with CIP pump of connected tanks |

| 27 | CIP return pump | 10T/H | SUS304, pump lift 24m ,hard alloy mechanical seal, inner shell mirror polished |

| 28 | Power system unit | ||

| 29 | Cold water equipment | 7000 kcale per hour, air cooling refrigeration | |

| 30 | Hot water boiler | 1000Kg/h, outlet temperature is 90 °C | |

| 31 | Installation system | Stainless steel piping system,power piping system, electric controlling box, electric installation material, installation and commissioning | |

A mini dairy milk processing plant is a compact and efficient facility designed for small-scale production of various milk products. Here are some key highlights of such a plant:

1. Modular Design: Mini dairy plants typically feature a modular design, allowing for easy installation, expansion, and customization according to specific needs and space constraints. Components are often pre-fabricated and can be assembled on-site quickly.

2. Compact Footprint: These plants are specifically engineered to occupy minimal space, making them suitable for urban or rural settings where land availability may be limited. They can be set up in a small building, a modified container, or even a purpose-built mobile unit.

3. Integrated Processing Lines: A mini dairy plant integrates multiple processing stages into a single, streamlined system, including reception, standardization (fat and solids adjustment), pasteurization or sterilization, homogenization, chilling, and packaging. This ensures efficient handling of milk from raw material receipt to finished product output.

4. Automated Control Systems: To enhance efficiency and minimize human error, mini dairy plants often incorporate advanced automation and control systems. These may include PLC (Programmable Logic Controller) controls, touch-screen interfaces, and data logging capabilities for monitoring critical process parameters like temperature, pH, and flow rates.

5. Energy Efficiency: Given their smaller scale, mini dairy plants can be designed with energy-saving features such as heat recovery systems, which capture and reuse heat generated during processing (e.g., from pasteurization) to preheat incoming milk or for other purposes within the plant. Energy-efficient equipment and insulation also contribute to reduced energy consumption and operating costs.

6. Flexibility in Product Range: Despite their size, mini dairy plants can handle a variety of milk products, such as pasteurized milk, UHT (Ultra High Temperature) milk, flavored milk, yogurt, cheese, cream, and butter. The ability to switch between different recipes and packaging formats allows producers to cater to diverse market demands and capitalize on seasonal trends.

7. Adherence to Regulatory Standards: Mini dairy plants are designed to comply with local and international food safety regulations, including HACCP (Hazard Analysis and Critical Control Points) principles. Sanitary design, regular cleaning and maintenance procedures, and built-in quality control measures ensure that the final products meet the required microbiological and nutritional standards.

8. Sustainable Practices: Many mini dairy plants prioritize sustainable operations by minimizing water usage through recycling and reusing processes, implementing waste management strategies (e.g., solid waste utilization for animal feed or composting), and utilizing eco-friendly materials in construction and packaging.

9. Economies of Scale for Small Producers: By providing an affordable entry point into the dairy industry, mini dairy plants enable small farmers, cooperatives, or entrepreneurs to process their own milk locally, reducing dependence on large processors and potentially increasing profit margins through value-added product development and direct-to-consumer sales.

10. Training and Technical Support: Manufacturers of mini dairy plants offer comprehensive training programs, user manuals, and ongoing technical support to ensure operators can effectively run and maintain the equipment, maximizing its performance and longevity.

In summary, a mini dairy milk processing plant combines compactness, modularity, and advanced technology to provide small-scale producers with a versatile, efficient, and regulatory-compliant solution for transforming raw milk into a variety of high-quality dairy products.

Pre sales services

Post sales services

1.

Equipment warranty period

: We provide a one-year free warranty service for mechanical equipment. If any non-human caused problems occur during the warranty period, we will provide free repair or replacement services.

2.

Maintenance and upkeep services

: We provide regular or irregular equipment maintenance and upkeep services to ensure the normal operation of the equipment. We will provide 24-hour online technical support services.

3.

Accessory supply

: We guarantee to provide original factory accessories in a timely manner in case of equipment damage or replacement of parts.

4.

Training services

: In order to enable customers to effectively operate and maintain equipment, we will provide equipment operation and maintenance training.

5.

Installation and debugging

: We will provide equipment installation and debugging services to ensure that the equipment is installed correctly and can operate normally.