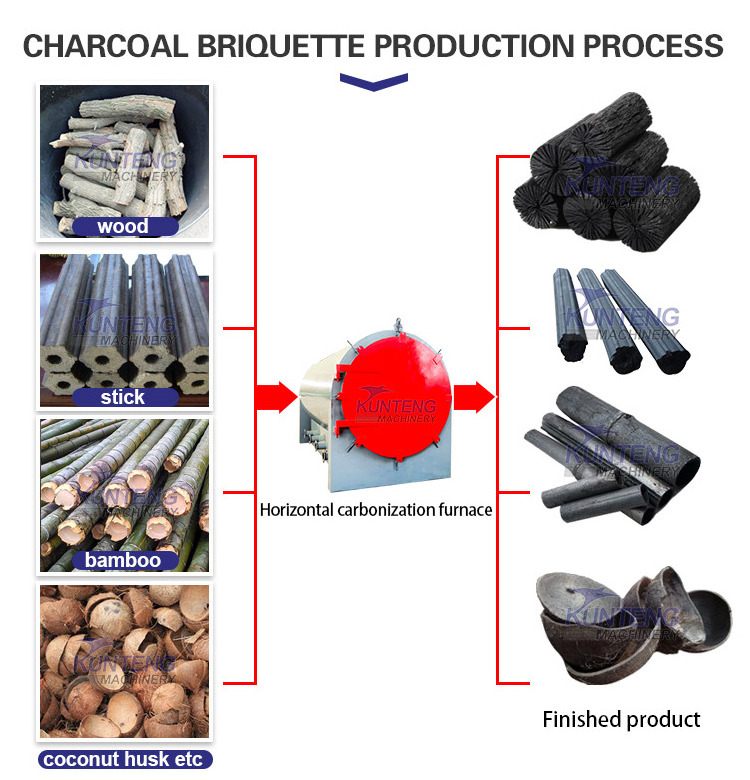

Raw materials could be any biomass, such as wood, coconut shell, palm shell, bamboo, some crops, rice husk, corncob, peanut shell, furfural residue, semi-coke, waste wood like branches, trunks, logs, bark, stumps, roots, miscellaneous wood, wood board, wooden pallet, sawdust, shavings, wood chips, fruit wood, poplar etc. All those materials could use our charcoal carbonization furnace to carbonize into charcoal.

- Product Details

- {{item.text}}

Quick Details

-

Brand Name:

-

KUNTENG

-

Effective Volume:

-

2-15m³

-

Dimension(L*W*H):

-

2.1*2.3*1.9m

-

Voltage:

-

110/220/380/415

-

Power:

-

2.5kw

-

Weight (KG):

-

4500

-

Applicable raw materials:

-

Wood, coconut shell, bamboo and any biomass material

-

Function:

-

Carbonize wood, coconut shell, bamboo etc into charcoal

-

Product name:

-

Lump charcoal making machine

-

Advantage:

-

High Carbonization Rate

-

Fuel:

-

Coal, charcoal, firewood, natural gas or biomass pellets

-

Final product:

-

Biochar

-

Capacity:

-

1T-5T

-

Carbonization time:

-

6-12 Hours

-

Color:

-

Customer's Request

-

Weight:

-

1T-6T

Quick Details

-

Place of Origin:

-

Henan, China

-

Marketing Type:

-

Hot Product 2022

-

Core Components:

-

Furnace

-

Brand Name:

-

KUNTENG

-

Effective Volume:

-

2-15m³

-

Dimension(L*W*H):

-

2.1*2.3*1.9m

-

Voltage:

-

110/220/380/415

-

Power:

-

2.5kw

-

Weight (KG):

-

4500

-

Applicable raw materials:

-

Wood, coconut shell, bamboo and any biomass material

-

Function:

-

Carbonize wood, coconut shell, bamboo etc into charcoal

-

Product name:

-

Lump charcoal making machine

-

Advantage:

-

High Carbonization Rate

-

Fuel:

-

Coal, charcoal, firewood, natural gas or biomass pellets

-

Final product:

-

Biochar

-

Capacity:

-

1T-5T

-

Carbonization time:

-

6-12 Hours

-

Color:

-

Customer's Request

-

Weight:

-

1T-6T

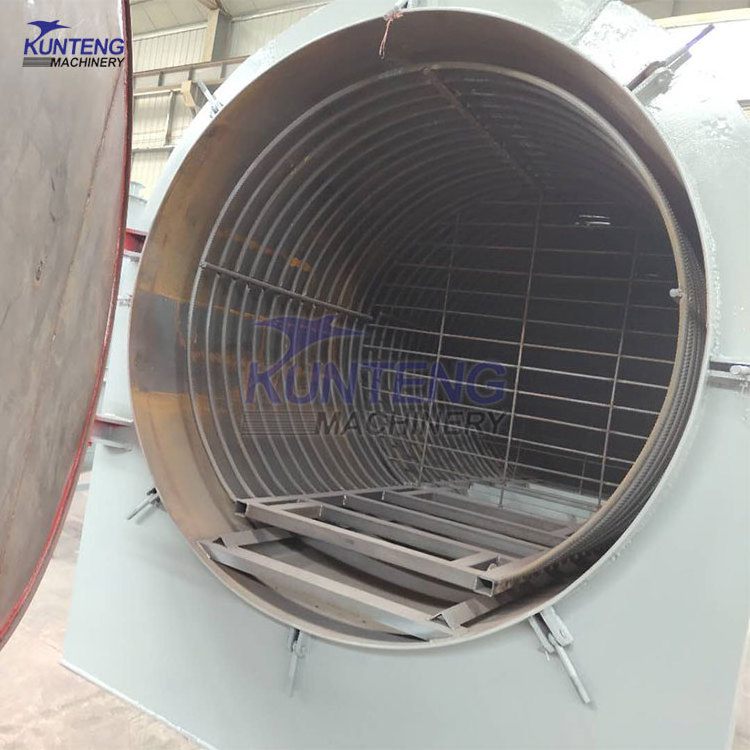

PRODUCT OVERVIEW

Biochar machine

is also called Horizontal carbonization furnace,

it is used to carbonize wood, coconut shell,

palm shell, waste wood, bamboo and any biomass into charcoal. The price of charcoal on the market is five times higher than that of wood and biomass.

Applicable raw materials

Biochar machine

is very easy to operate, just put the raw material into the furnace, few hours later take it out, it will all become charcoal.

CUSTOMER SITES

Below are Installation Sites of Our Customers

After reach deals, KUNTENG Engineer will fly to your address, install and adjust machine for you for free. Also train you operation skills, until you are satisfied.

Our team have more than 20 years export experience for carbonization furnace. We can help optimize the drying process according to the property of different materials, production scale, application requirements, cost control, automation level and site condition.

|

TYPE

|

SIZE

|

CAPACITY(kg)

|

GROSS WEIGHT(kg)

|

THICKNESS OF STEEL

|

|

KT1500-1000

|

1.5*φ1m

|

700

|

400

|

6mm

|

|

KT1500-1200

|

1.5*φ1.2m

|

850

|

500

|

6mm

|

|

KT1500-1400

|

1.5*φ1.4m

|

1000

|

700

|

6mm

|

|

KT1500-1700

|

1.5*φ1.7m

|

1600

|

1000

|

8mm

|

|

KT2000-1700

|

2*φ1.7m

|

2200

|

1300

|

8mm

|

|

KT3000-1500

|

3*φ1.5m

|

3100

|

2500

|

12mm

|

|

KT3000-1700

|

3*φ1.7m

|

4000

|

2700

|

12mm

|

|

KT3000-1700

|

4.5*φ1.7m

|

6300

|

3200

|

12mm

|

|

KT4500-2000

|

4.5*φ2m

|

9600

|

3700

|

12mm

|

SIMILAR PRODUCTS

We also have other types of carbonization furnaces to meet the different needs of our customers.

Hoisting carbonization furnace

Features of hoisting carbonization furnace is many of it could connect and work together, also can play the foundation to put underground.

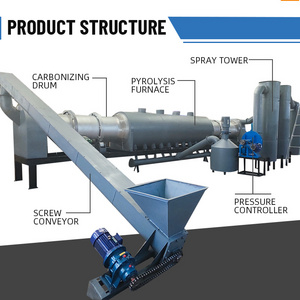

Continuous carbonization furnace

Continuous carbonization furnace is suitable for carbonization of small pieces materials, such as sawdust, wood chip, wood dust, jujube stone, walnut shell, apricot shell, peanut shell, coffee husk, straw, etc. You could put those small pieces materials directly in to the furnace and it won't burned. The advantages of Continuous carbonization furnace is zero pollution, zero emission, save labor, high capacity, energy-saving consumption, the high degree of automation and advanced technology, which is suitable for large-scale production.

PRODUCTION LINE

The process of making charcoal

Firstly, wood, coconut shell, palm shell, bamboo and other biomass are carbonized into charcoal by carbonization furnace. According to customer's raw material, you can choose continuous carbonization furnace, horizontal carbonization furnace and hoisting carbonization furnace.

Secondly, charcoal can be crushed into charcoal powder by dust-free grinder.

Thirdly, charcoal powder are stirred by Mixer.

At the end, charcoal powder can be shaped by Punching press charcoal machine.

The whole charcoal briquette machine production line are fully automatic.

CUSTOMER VISIT

KUNTENG Group Advantage:

1. Over 100 employees, 98% professional technical personnel; 2. Factory size over 10,000 square meters;

3. Exported over 80 countries, 300 global partners;

4. Customize Production Line;

5. More than 20 years experience for charcoal briquette machine production line.

3. Exported over 80 countries, 300 global partners;

4. Customize Production Line;

5. More than 20 years experience for charcoal briquette machine production line.

Package and Shipment

Biochar machine

will be wrapped up with plastic film first (including the motor). The plastic film bag wrapped machine, according to the size and weight to make wooden or iron box, put machine in and fixed the box after loading. (The box material can be made as your requirements) The carbonization furnace parts need to be put in a fixed container, should be fixed well, lest collision and wear or lost.

COMPANY PROFILE

Henan Kunteng Machinery Manufacture Co., Ltd aims to build a brand enterprise with satisfaction of customers. Our company will provide satisfactory products with the latest technology, reliable quality favorable price and perfect service,we welcome friends from all circles. Our factory mainly produces

Biochar machine biomass wood charcoal making machine price for charcoal making machine

.

FAQ

Q1: Why should you buy from us not from other suppliers?

A1: We have more than twenty years experience of making carbonization furnace, we always focus on improving the quality, use the best materials and high technology for making our products. We also have the most perfect after-sales service. All customers who have purchased our products will come back buy our equipment again.

Q2 : How can we guarantee quality?

A2 : Always a pre-production sample before mass production. Always final Inspection before shipment.

Q3: May I visit your company?

A3: Warmly welcome you to visit our company, consultation, sample testing, please contact us before making an appointment.

Q4: How much is the shipment charge?

A4: It depends on your import port and the number of machines, different sizes, different quantities, different port shipping costs.

Q5: How to install and operate the machine?

A5: We will provide the installation and operation manual, you can follow the manual for installation and operation, can also provide you with video or online support.

Other information and services we could provide

Accepted Delivery Terms: EXW, Express Delivery;

Accepted Payment Currency: USD, EUR, JPY, CAD, AUD, HKD, GBP, CNY;

Accepted Payment Type: T/T, L/C, Money Gram, Cash, Escrow;

Feel free to contact us if you have any questions.

Hot Searches