- Product Details

- {{item.text}}

Quick Details

-

Power:

-

depends

-

Dimension(L*W*H):

-

depends

-

Weight:

-

211 kg

-

After-sales Service Provided:

-

No overseas service provided

-

color:

-

yellow, white, blue, red, orange, grey

-

usage:

-

sand washing, dewatering, grading, recycling

-

new tech:

-

combine the sand washing and screening and recycling machines as one

-

model:

-

standard and customized

-

market:

-

Indonesia,India,Malaysia,Philippines,Sri Lanka, Australia, UAE...

-

preference:

-

first order with free spare parts

-

sales service:

-

sales man, engineers and technician all at your service

-

superiority:

-

manufacturer guards you the good quality and low price

-

motor type:

-

AC

Quick Details

-

Place of Origin:

-

China

-

Brand Name:

-

LZZG

-

Voltage:

-

depends

-

Power:

-

depends

-

Dimension(L*W*H):

-

depends

-

Weight:

-

211 kg

-

After-sales Service Provided:

-

No overseas service provided

-

color:

-

yellow, white, blue, red, orange, grey

-

usage:

-

sand washing, dewatering, grading, recycling

-

new tech:

-

combine the sand washing and screening and recycling machines as one

-

model:

-

standard and customized

-

market:

-

Indonesia,India,Malaysia,Philippines,Sri Lanka, Australia, UAE...

-

preference:

-

first order with free spare parts

-

sales service:

-

sales man, engineers and technician all at your service

-

superiority:

-

manufacturer guards you the good quality and low price

-

motor type:

-

AC

LZZG Sand Washing & Recycling Machine Is The Best Machine In China !

The First Brand Of Sand Washer In China —— LZZG !

Product Overview

LZ Sand Washing & Recycling Machine

Working Principle

*Washing:

The bucket is driven by the motor through the reducer and rotates in circle. There are many sand storage web grooves and bucket screen for sand storage and primary dewatering. When the bucket moves, sand can be put out by sand storage web groove after being cleaned in the cleaning tank and primary dewatered on the bucket screen.

*Recycling: Flowing slurry water is extracted by slurry pump, fine sand is collected by the centrifugal force of the cyclone, then fed to the polyurathane screen from the apex spray. The 0.16-3mm fine sand and water are efficiently separated through the vibration screen.

*Dewatering: coarse sand (3-10mm) and fine sand (0.16-3mm) are fed onto polyurathane vibrating screen for dewatering.

*Recycling: Flowing slurry water is extracted by slurry pump, fine sand is collected by the centrifugal force of the cyclone, then fed to the polyurathane screen from the apex spray. The 0.16-3mm fine sand and water are efficiently separated through the vibration screen.

*Dewatering: coarse sand (3-10mm) and fine sand (0.16-3mm) are fed onto polyurathane vibrating screen for dewatering.

Technical Parameters

|

Model

|

Capacity (t/h)

|

Dianater Impeller (mm)

|

Hydrocyclone (mm)

|

Screen Panel (mm)

|

Power (kw)

|

Weight (kg)

|

Overall Size

(mm)

|

|

LZ1808-55-1224

|

20-40

|

1800*800

|

250*2

|

1200*2400

|

29.4

|

4800

|

5800*5000*1950

|

|

LZ2612-65-1530

|

30-60

|

2600*1200

|

300*2

|

1500*3000

|

40

|

5390

|

5800*5560*2750

|

|

LZ3016-65-1842

|

40-80

|

3000*1600

|

300*2

|

1800*4200

|

46.5

|

10500

|

7950*6200*3700

|

|

LZ3016-75-1842J

|

60-100

|

3000*1600

|

350*2

|

1800*4200

|

57.5

|

11200

|

7950*6200*3700

|

|

LZ3620-120-2442J

|

100-150

|

3600*2000

|

300*4

|

2400*4200

|

89.5

|

15150

|

8500*6800*3700

|

|

LZ3624-140-3048J

|

120-200

|

3600*2400

|

350*4

|

3000*4800

|

115

|

16990

|

7950*7400*4100

|

|

LZ3624-140-3060J

|

120-200

|

3600*2400

|

350*4

|

3000*6000

|

122

|

18620

|

7950*7400*4100

|

|

LZ4230-180-3660J

|

160-250

|

4200*3000

|

300*6

|

3600*6000

|

149

|

24600

|

8580*8020*4860

|

Features & Benefits

1.Higher sand quality, lower moisture content.

2.Recycled fine size 0.16-3mm sand, lower mud content.

3.Compact structure and easy installation.

4.High productivity and 95% of fine particles kn the material can be recycled.

5.Solve cleaning problem of seclimentation tank and improve economic performance at the same time.

2.Recycled fine size 0.16-3mm sand, lower mud content.

3.Compact structure and easy installation.

4.High productivity and 95% of fine particles kn the material can be recycled.

5.Solve cleaning problem of seclimentation tank and improve economic performance at the same time.

Product Display

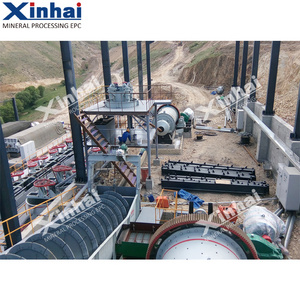

Successful Project

Project in Thailand

Project in India

Project in Sri Lanka

Certifications

Our Service

Pre-sale:

Passionate We offer you the early planing of the project,the best process flow design,choose the best appropriate

equipment model to design products according to your special needs.

equipment model to design products according to your special needs.

Sale

:

Integrity All products are strictly inspected with the drawings and process flow according to the contract before they delivery from storage.We assigned the technicians to the producing spot to provide installation guide, testing and training.

After-sale

:Considerate To establish good business relationship,we always periodical visit to the users.We could give you the definite reply during 24 hours when the users meet some problems in the producing process.

FAQ

1

.Does your product in stock?

Yes,once you place the order,the delivery will be done within one week.

2.Can the machine parts be replaced?

Yes,You can get them directly from us in a low price, and we make sure the easy maintenance and replacement .

3.How is the quality of your products?

Our products are manufactured strictly according to national and international standard, and we take a test on every product before delivery.Please check our working site. If our quality is not good, i don't think we can sell so well.

4.Guaranteed?

Yes. If products'quality is not consistent with the description as we described or the promise before you place order, we promise 100% refund.

5.How about price?

Yes, we are factory and be able to give you the lowest price than market one, and we have a policy that " for saving time and absolutely honest business attitude,we quote as low as possible for any customer, and discount can be given according to quantity".

Please contact us for more details and discount !

Hot Searches