- Product Details

- {{item.text}}

Quick Details

-

Place of Origin:

-

Shandong, China

-

Brand Name:

-

SH

-

Model Number:

-

SH-50

-

Product name:

-

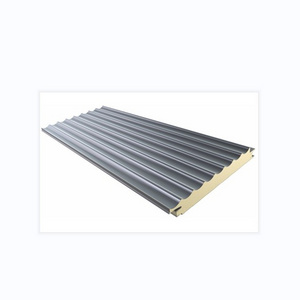

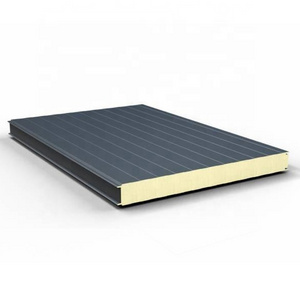

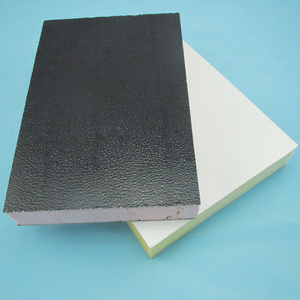

Rock Wool Sandwich Panel

-

Keyword:

-

thickened corrugated rock wool sandwich panels

-

MOQ:

-

200 Square Meters

-

engineering solution ability:

-

Cross Categories Consolidation

-

application scenario:

-

Warehouse

-

design style:

-

Industrial

-

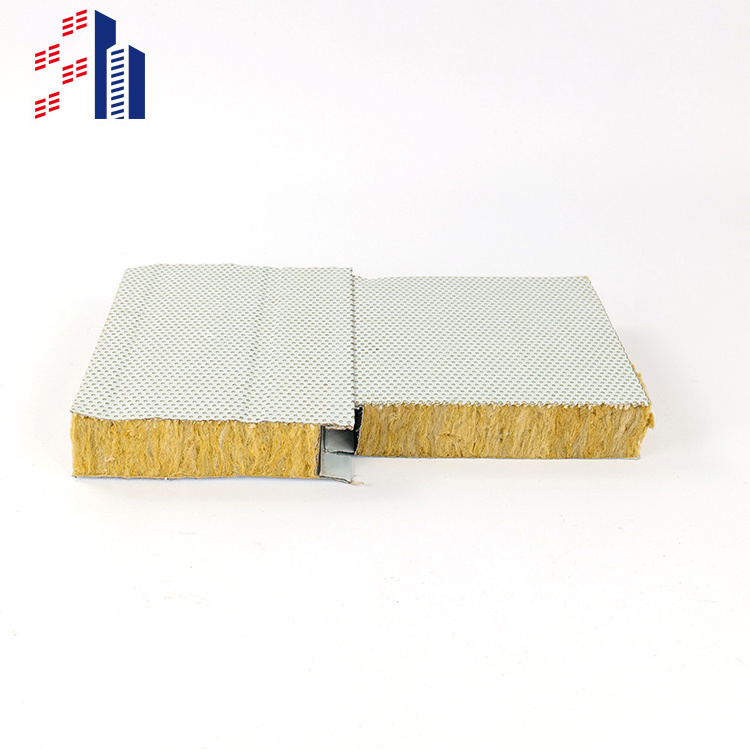

Surface material:

-

Al-zn Alloy Coated Steel Sheet

-

Core material:

-

Rock Wool Board

-

Package:

-

Shrink Package

-

Main market:

-

ARCHITECTURE

Quick Details

-

Project Solution Capability:

-

graphic design, 3D model design, total solution for projects, Cross Categories Consolidation, Others

-

Application:

-

Hotel/Villa/Apartment/Office Building

-

Design Style:

-

Industrial

-

Place of Origin:

-

Shandong, China

-

Brand Name:

-

SH

-

Model Number:

-

SH-50

-

Product name:

-

Rock Wool Sandwich Panel

-

Keyword:

-

thickened corrugated rock wool sandwich panels

-

MOQ:

-

200 Square Meters

-

engineering solution ability:

-

Cross Categories Consolidation

-

application scenario:

-

Warehouse

-

design style:

-

Industrial

-

Surface material:

-

Al-zn Alloy Coated Steel Sheet

-

Core material:

-

Rock Wool Board

-

Package:

-

Shrink Package

-

Main market:

-

ARCHITECTURE

SH Black Steel Building Kit Polyurethane Thermocol FRP XPS Cladding Sandwich Panels Wall Roof Screw China

Product introduction

The paint coating on the surface of the plate is made from high weather-resistant polyester paint or fluorocarbon paint, and the color of the paint surface will not fade for 15 years. Galvanized steel plate is made of 55% aluminum and 43% zinc, which can last for 45 years without rusting.

It is mainly used for ceiling isolation of movable roofs, walls and air purification rooms, with beautiful appearance, moderate price, resource saving, thermal insulation, fire prevention and flame retardant, and in line with national standards.

Product Details

Advantages of new model rock wool:

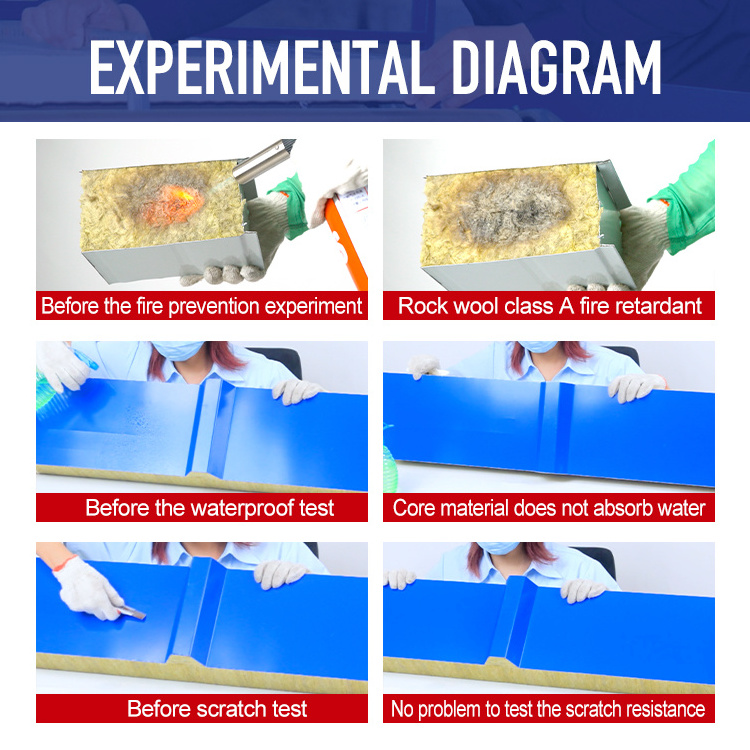

1.Non inflammability and Level A fireproof performance

2.Excellent performance in thermal insulation

3.Biodegradable and environment-friendly

4.Hydrophobic property and high ageing resistance

5.Sound absorption and noise reduction

6.High acidity coefficient can greatly reduce the corrosive action on metals.

2.Excellent performance in thermal insulation

3.Biodegradable and environment-friendly

4.Hydrophobic property and high ageing resistance

5.Sound absorption and noise reduction

6.High acidity coefficient can greatly reduce the corrosive action on metals.

|

Compressive strength

|

|

85kpa

|

|

|

|||

|

Shear strength

|

|

60kpa

|

|

|

|||

|

Tensile strength

|

|

170kpa

|

|

|

|||

|

Slag ball content

|

|

<5 (size of coarse slag ball>0.25mm)

<30 ( size of coarse slag ball>63μm)

|

|

|

|||

|

Thermal conductivity of rock wool panel

|

|

0.038(average temperature 20℃)

|

|

|

|||

|

Fireproof rating

|

|

Noninflammable material

|

|

|

|||

|

Reaction to fire

|

|

Grade A

|

|

|

|||

|

Fire-resistant limit(FRL)

|

|

According to the structure and thickness of sandwich panel,FRL is between 30mins and 240mins.

|

|

|

|||

|

Hydroscopicity

|

|

<1

|

|

|

|||

|

Hydrophobicity(specific to hydroph-obic products)

|

|

≧98

|

|

|

|||

|

Aging and expansion rate

|

|

≦5(thickness change rate after 24 hours under the state of 65℃)

|

|

|

|||

|

Melting temperature

|

|

>1000℃

|

|

|

|||

|

Fiber diameter

|

|

≦7μm

|

|

|

|||

Note:usually the material with low thermal conductivity is regarded as thermal insulation material ( it is stipulated that all the materials with a thermal conductivity no more than 0.12W/(m.K) when the temperature is lower than 350℃ called thermal insulation materials in national standard.),and the materials with a thermal conductivity less than 0.05w/m.K is named high-efficient thermal insulation material.

|

Product name

|

|

Polyurethane Edge Rock Wool

|

|

|

|||

|

Effective Coverage

|

|

400-1000mm

|

|

|

|||

|

Steel Thickness

|

|

0.4-0.7

|

|

|

|||

|

Surface Pattern

|

|

Small Pipple,Middle Groove,Pure Flat

|

|

|

|||

|

Stock Color

|

|

White Gray,Silver,Sea Blue,Etc.

|

|

|

|||

|

Recommended Coating

|

|

Fluorocarbon Coating Pvdf,Smp Coating,Hdf Coating,Polyester Pe Coating,Etc

|

|

|

|||

|

Core Thickness

|

|

50,75,100,Etc.

|

|

|

|||

|

Core Material Name

|

|

Polyurethane

|

Polyurethane Edge Glass Wool

|

Polyurethane Edge Rock Wool

|

|||

|

Thermal Conductivity

|

|

0.019-0.024w/m.k

|

0.035-0.041w/m.k

|

0.037-0.043m.k

|

|||

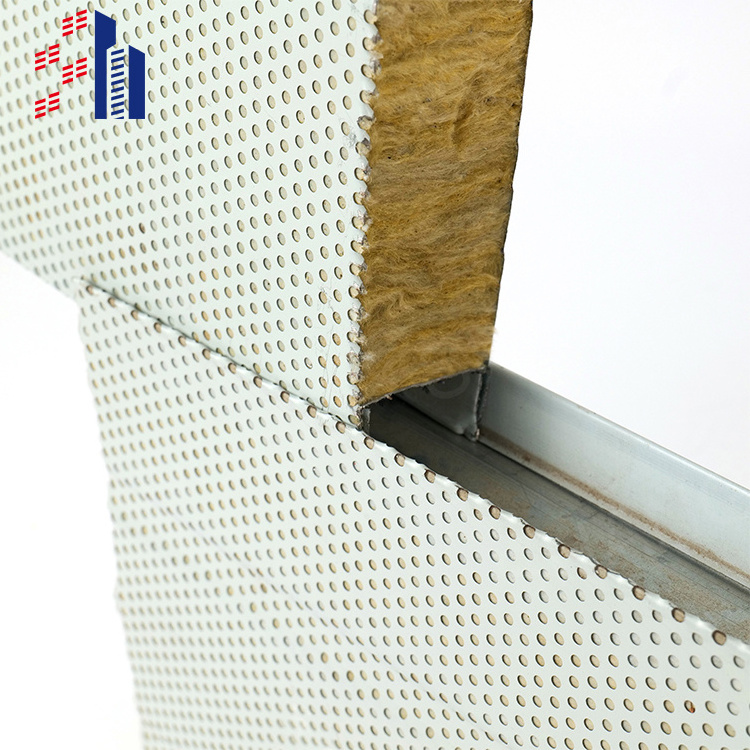

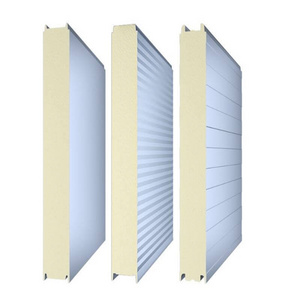

The application of exclusive fireproof PIR side sealing technology increases the air-tightness and water-tightness in lap-joints,thus preventing the cold bridge from happening,and at the same time,the separation of steel sheets from core materials is avoided while transportation and installation.

ROCK WOOL Sandwich panels can suffer from high temperature of 600℃,it won't burn when the flame

extinguished.Also our products have a good performance of water resistant and scratches prevention .

Welcome to consult us.

We supply the service of customized

.

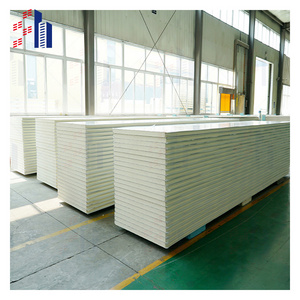

Production Process

1. The conveyance of rock wool/glass wool is a major highlight in the whole production line.The rigidity of sandwich panels increases greatly and the flatness and beauty of sandwich panels are guaranteed through loading,lifting,cutting,conveying,lateral moving,90° rotation arraying,edge milling and other links.

The rock wool/glass wool core material strips are cross-butted ,thus the strength and tear resistance of composite plates increase greatly.

2.After intensive mixing,under certain pressure,components of chemical materials are sprayed onto the upper and lower steel sheets evenly.The guaranteed spraying thickness,the widened bonding surface between rock wool and steel sheet as well as the stronger bond enhance the strength of sandwich panels greatly.

3.To further improve the panel's performance ,such as metal skins' peel strength,no cold bridge and no dewing,50 mm polyurethane edge sealing is added to both sides in the production process.

4.The application of double crawler machine changes the traditional production process in which rolls keep a linear contact with steel sheets. By this way, rolls keep a plane contact with steel sheets,run synchronously with sandwich panels and solidify completely in double crawlers,thus the flatness of sandwich panels and the bonding stability between core materials and steel sheets are ensured

We pay full attention to every step in production:

2.After intensive mixing,under certain pressure,components of chemical materials are sprayed onto the upper and lower steel sheets evenly.The guaranteed spraying thickness,the widened bonding surface between rock wool and steel sheet as well as the stronger bond enhance the strength of sandwich panels greatly.

3.To further improve the panel's performance ,such as metal skins' peel strength,no cold bridge and no dewing,50 mm polyurethane edge sealing is added to both sides in the production process.

4.The application of double crawler machine changes the traditional production process in which rolls keep a linear contact with steel sheets. By this way, rolls keep a plane contact with steel sheets,run synchronously with sandwich panels and solidify completely in double crawlers,thus the flatness of sandwich panels and the bonding stability between core materials and steel sheets are ensured

Raw material Producing Warming Cutting Sanding machine cutting choosing,packaging, Loading.

Product application

Product features :

Screw concealed fixed appearance,without exposed screws on surface;

Elegant and smooth building wall,smooth and even surface substituting the decorative effect of aluminum curtain wall; Extreme high bending resistant capacity and superior mechanical property,reducing the dependence auxiliary steel structures.

Screw concealed fixed appearance,without exposed screws on surface;

Elegant and smooth building wall,smooth and even surface substituting the decorative effect of aluminum curtain wall; Extreme high bending resistant capacity and superior mechanical property,reducing the dependence auxiliary steel structures.

Metal sandwich panels are easy to install, fast in construction, lower in material and maintenance costs than other materials, sound-proof, shock-proof, heat-insulating and moisture-proof, beautiful and durable, and can be used all the year round without exception.

Hot Searches