- Product Details

- {{item.text}}

Quick Details

-

Place of Origin:

-

Anhui, China

-

Brand Name:

-

Junshuo

-

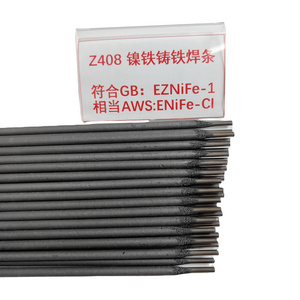

Model Number:

-

ENi-CI

-

Operating Current:

-

International Standard

-

Application:

-

repairing gray cast iron and ductile iron

-

Product Name:

-

Cast Iron Welding Electrode

-

Color:

-

Black

-

Keyword:

-

Ni99

-

Standard:

-

AWS A5.15

-

MOQ:

-

100kgs

-

Samples:

-

1 pieces of Sample Fee

-

OEM:

-

Accept OEM

-

Delivery Time:

-

Within 7 Days

-

Packing:

-

1kg/plastic tube 10kgs/CTN

-

Advantage:

-

high strength, good plasticity

Quick Details

-

Material:

-

Ni99

-

Welding Current:

-

50-150A International Standard

-

Operating Temperature:

-

MIN 150°C International Standard

-

Place of Origin:

-

Anhui, China

-

Brand Name:

-

Junshuo

-

Model Number:

-

ENi-CI

-

Operating Current:

-

International Standard

-

Application:

-

repairing gray cast iron and ductile iron

-

Product Name:

-

Cast Iron Welding Electrode

-

Color:

-

Black

-

Keyword:

-

Ni99

-

Standard:

-

AWS A5.15

-

MOQ:

-

100kgs

-

Samples:

-

1 pieces of Sample Fee

-

OEM:

-

Accept OEM

-

Delivery Time:

-

Within 7 Days

-

Packing:

-

1kg/plastic tube 10kgs/CTN

-

Advantage:

-

high strength, good plasticity

PRODUCTS DESCRIPTION

Nickel-Based Electrodes for Cast Iron

Nickel-based cast iron electrodes for welding cast iron belong to cold welding electrodes for heterogeneous welds. The coating is strongly reducing graphite type, AC and DC dual-purpose, good process performance, and can be welded in all positions. The weld metal has good workability and the ability to withstand plastic deformation. In order to reduce the adverse effect of the hard and brittle structure in the fusion zone on the post-weld processability, so that the white layer is as small as possible, thinner and discontinuous, the cold welding process regulations should be strictly followed during welding.

|

Trade Mark

|

Equivalent to National Standard

|

Equivalent to AWS A5.15

|

|

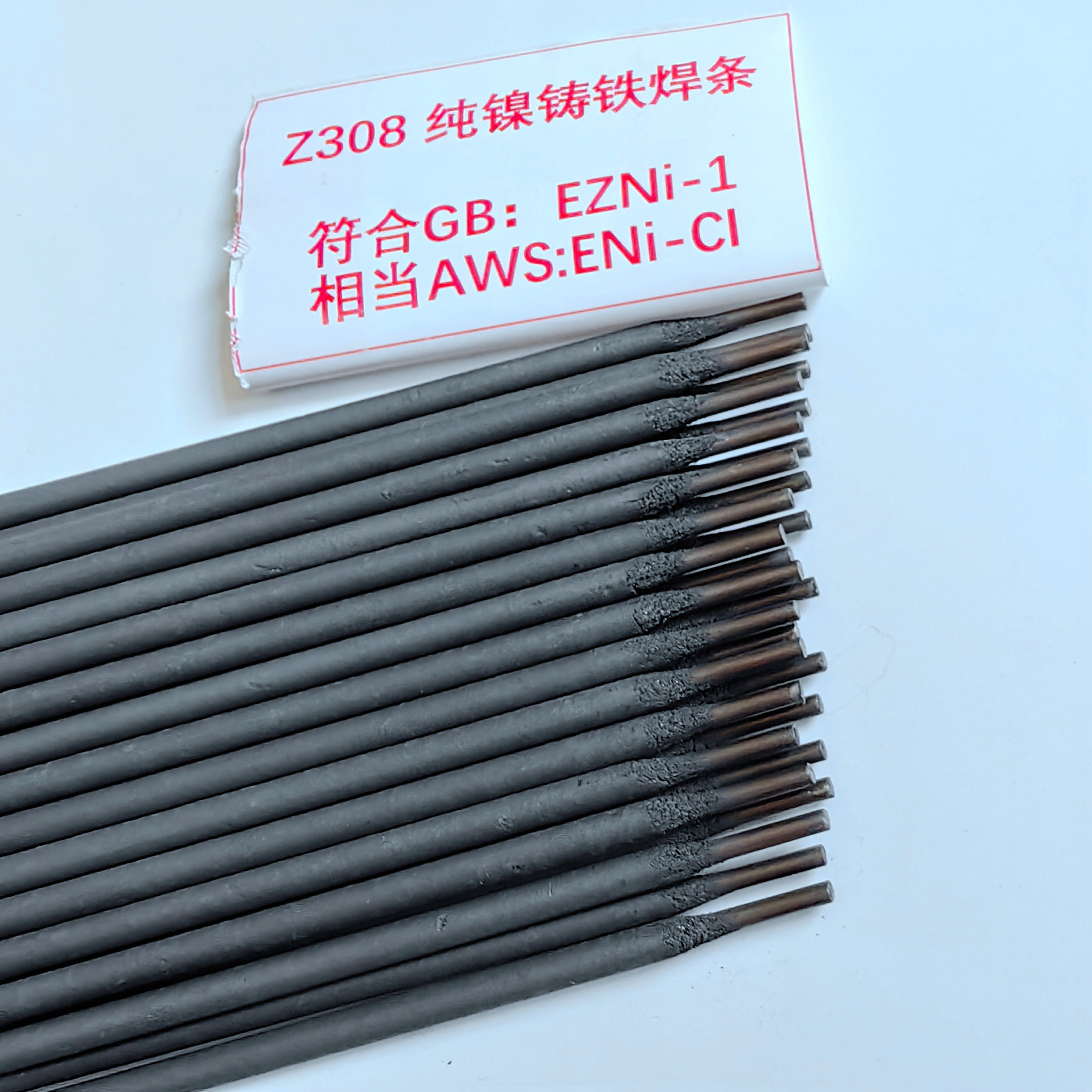

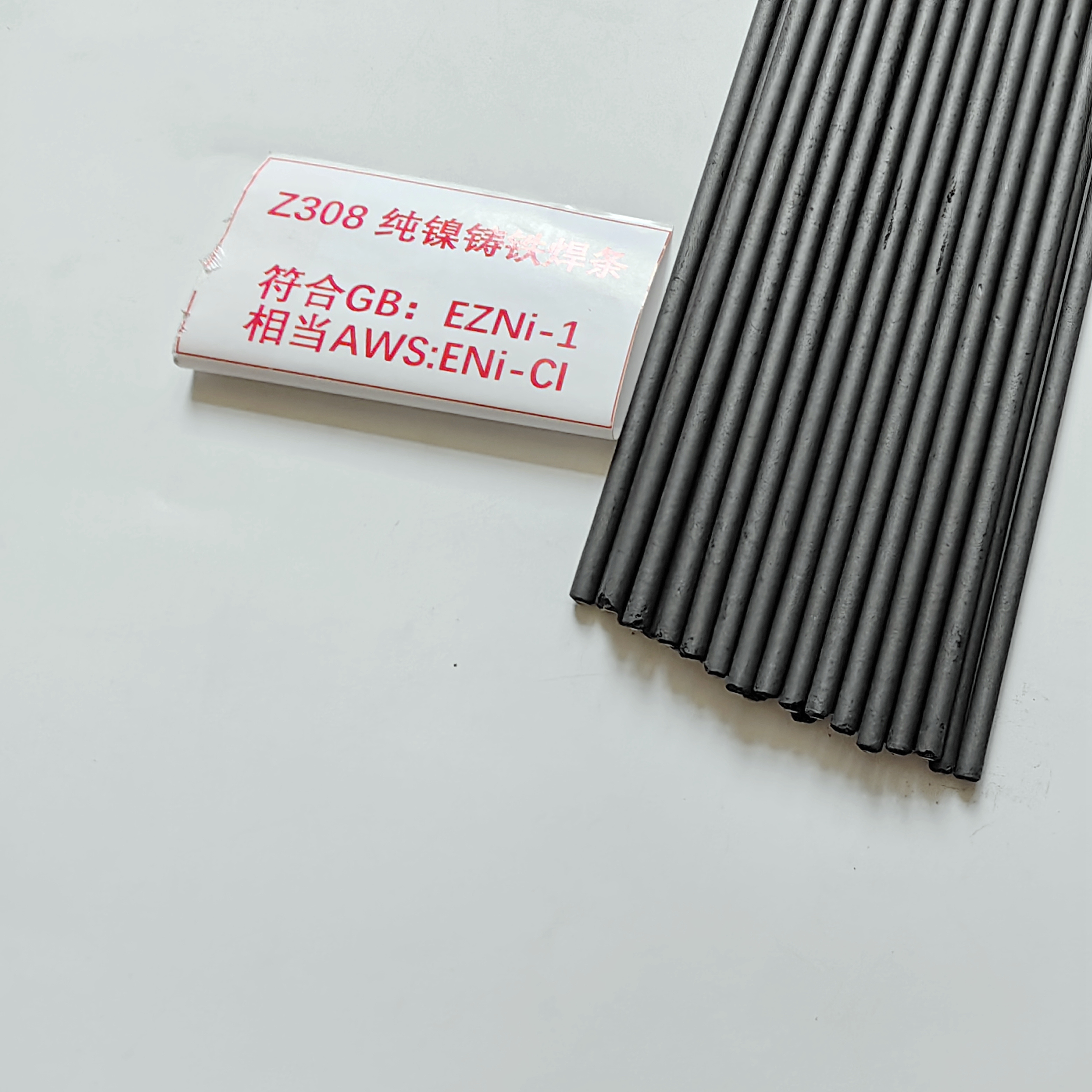

Z308

|

EZNi-1

|

ENi-CI

|

|

Z408

|

EZNiFe-1

|

ENiFe-CI

|

|

Z508

|

EZNiCu-1

|

ENiCu-B

|

Pure Nickel Cast Iron Welding Rod

Standard:

Conforms to GB EZNi-1

Comparable to AWS ENi-CI

Description:

Z308 is a cast iron electrode with pure nickel core and strong reducing graphite coating, which can be used for both AC and DC.The arc is stable during welding, the operation is convenient, and the weldment does not need to be preheated. It is an electrode with better comprehensive properties such as crack resistance, machinability, and weld strength among cast iron cold welding electrodes.

Purpose:

It can be used for important gray cast irons at room temperature or slightly preheated (to about 200°C), such as: processing surfaces of thin cast iron parts, welding of cylinder heads, engine blocks, gearboxes, machine tool guide rails, mechanical parts made of cast iron, etc. ,repair.

|

Chemical composition of deposited metal (%)

|

|

|

|

|

|

|||||

|

C

|

Si

|

Mn

|

Fe

|

Ni

|

S

|

|||||

|

≤2.0

|

≤2.5

|

≤1.0

|

≤8.0

|

≥90.0

|

≤0.03

|

|||||

|

Reference current: AC or DC

|

|

|

|

|

||||

|

Diameter(mm)

|

2.5

|

3.2

|

4.0

|

5.0

|

||||

|

Welding current (A)

|

50~80

|

80~100

|

110~140

|

150~180

|

||||

Precautions:

1. First remove the oil, sand, water, rust and other dirt from the welding part, and depending on the type of defect, take preparatory measures such as bevelling, cracking stop hole and molten pool shape.

2 If a large gap is to be filled, a layer of surfacing welding should be started from the surroundings first, and then gradually filled to the middle.

3 In order to avoid excessive melting of the base metal and reduce the white layer, during welding, try to use small current, short arc, narrow path, short path, and dispersed segmental welding. The length of each weld bead generally does not exceed 50mm. Continue welding until it is not hot. And hammer the weld immediately after welding to relax the stress and prevent cracks.

4 Before welding, theelectrode should be baked at about 150°C for one hour.

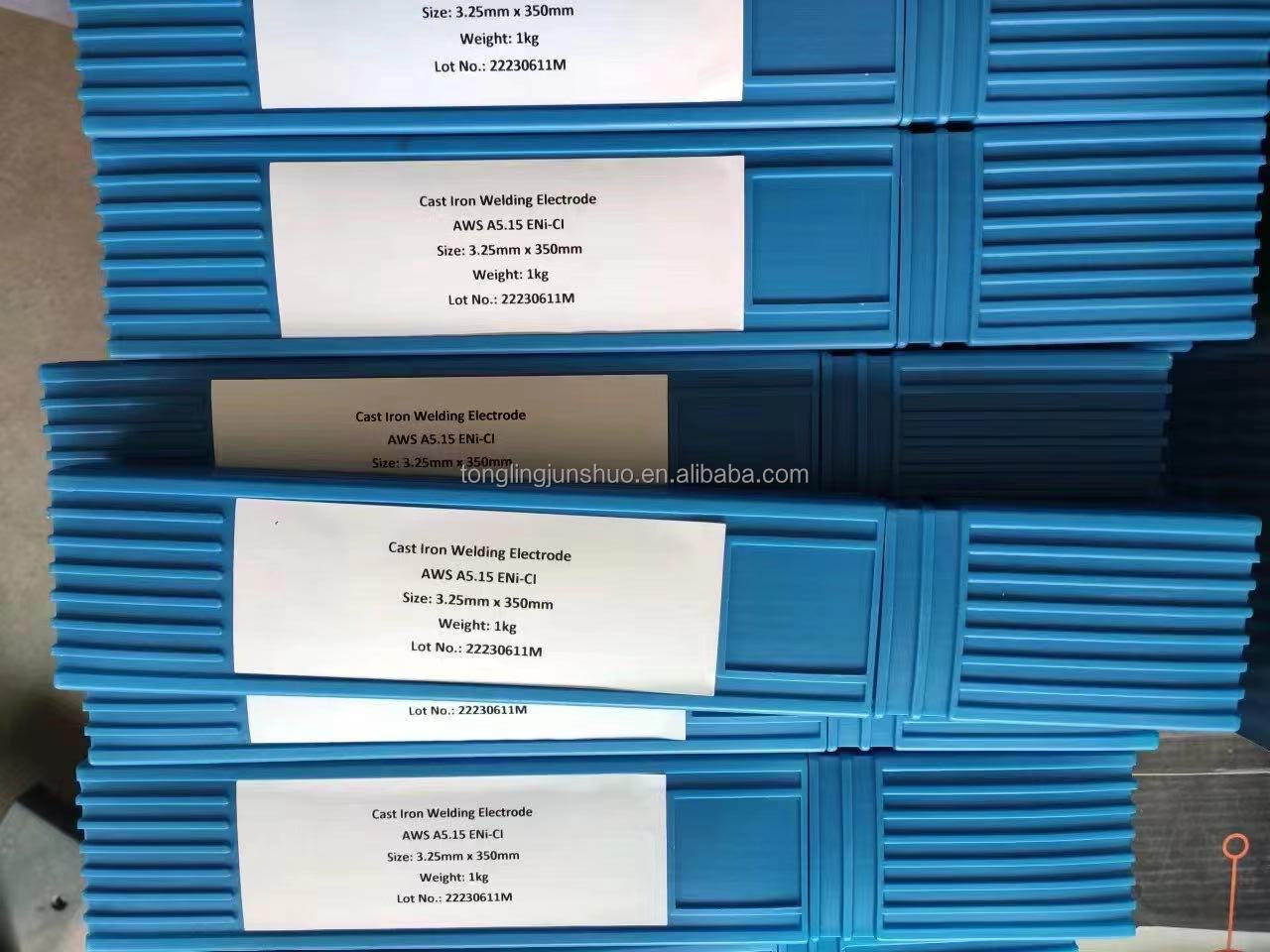

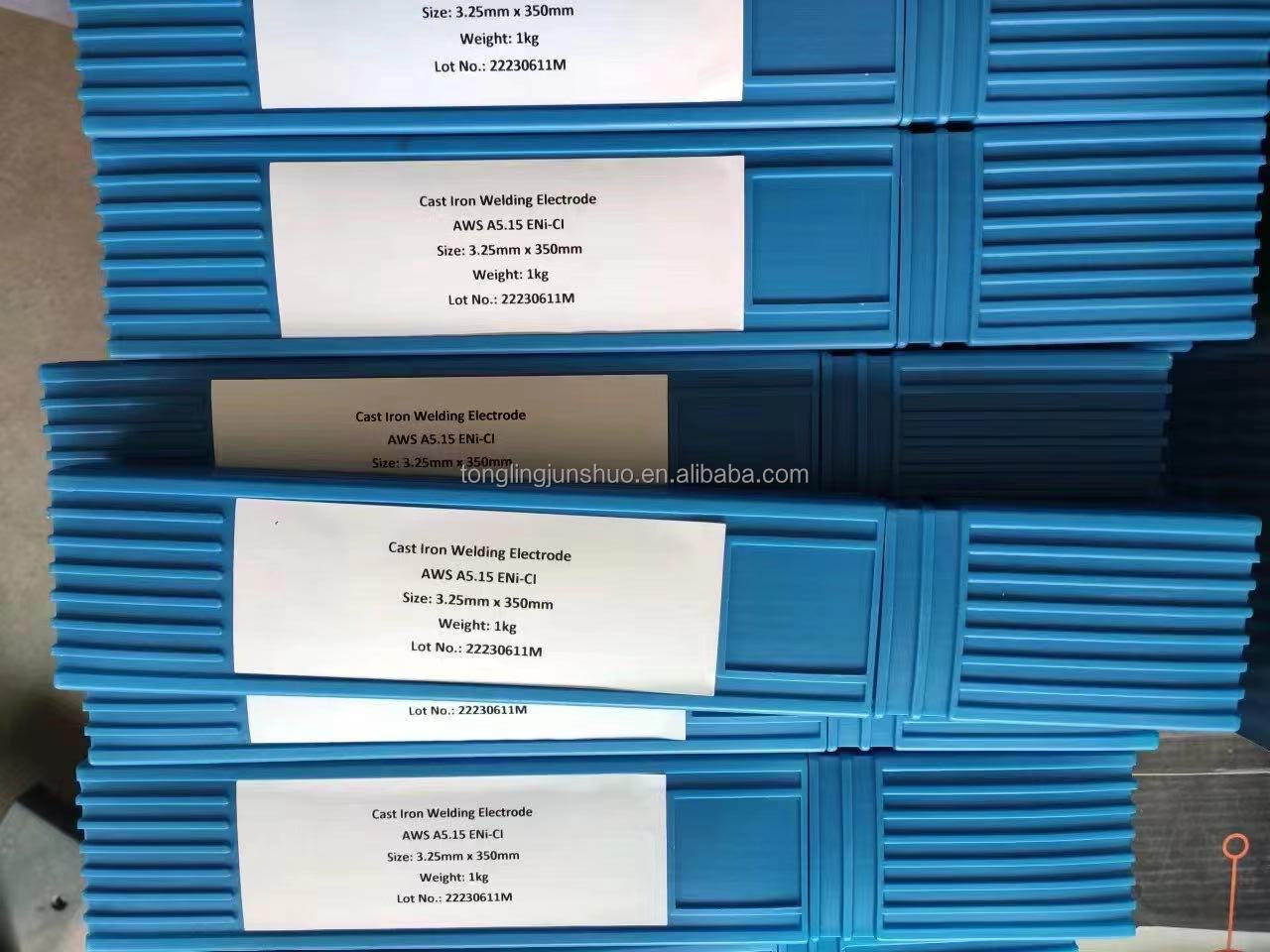

PACKING & SHIPPING

1kg in a blue plastic box

Can be customized according to customer needs

1kg in a Vacuum package

Can be customized according to customer needs

Or 2kg in a yellow plastic box

Can be customized according to customer needs

Then 10 boxes or 20 boxes in a CTN

Can be customized according to customer needs

Or 10LB in a red plastic box

Can be customized according to customer needs

T hen in a wooden case

Can be customized according to customer needs

RELATED PRODUCTS

PRODUCTS APPLICATION

Our products are suitable for automobile casting, high pressure valve iron, hydraulic rod, marine casting,aerospace casting, ocean exploration, precision machinery, deep sea scale, marine water scale, high pressure valve, etc, Our company is a world leader in the field of copper alloys, and has made outstanding contributions to the field of copper alloy welding in the world. Our company has been to Arabia, Dubai, Germany, the United States, France, the Middle East, and Vietnam for many times to conduct academic exchanges and promote the world. Development in the field of copper alloy welding.

ABOUT US

Tongling Junshuo New Materials Co., Ltd. is a professional manufacturer of welding

materials. To build a supply chain in the field of welding materials and provide customers with efficient quality services, the company adopts the latest production processes of continuous casting and rolling, mid-level traction and online annealing inaccordance with GB/T9460, BS EN14640, AWS and DIN standards. The company has passed the ISO 9001:2015 international quality system certification, with leading product technology, complete production and testing equipment, outstanding product performance and quality assurance. The company's leading products are: various types and specifications of copper welding wire, stainless steel welding wire, aluminum welding wire, CO2 gas shielded welding wire, carbon steel welding wire, etc., suitable for sintering of MIG, MAG, TIG, submerged arc welding, flux-cored welding, and electroslag welding Flux. The company has cooperated with large-scale brands in various countries and exported to many countries in Europe, Africa, the Middle East, Southeast Asia, etc. The company is committed to building a complete supply chain of welding materials and providing customers with high standards of quality first and service first. The company sincerely recruits brand agents from various countries to negotiate business cooperation and open a new window for welding materials in the world .

materials. To build a supply chain in the field of welding materials and provide customers with efficient quality services, the company adopts the latest production processes of continuous casting and rolling, mid-level traction and online annealing inaccordance with GB/T9460, BS EN14640, AWS and DIN standards. The company has passed the ISO 9001:2015 international quality system certification, with leading product technology, complete production and testing equipment, outstanding product performance and quality assurance. The company's leading products are: various types and specifications of copper welding wire, stainless steel welding wire, aluminum welding wire, CO2 gas shielded welding wire, carbon steel welding wire, etc., suitable for sintering of MIG, MAG, TIG, submerged arc welding, flux-cored welding, and electroslag welding Flux. The company has cooperated with large-scale brands in various countries and exported to many countries in Europe, Africa, the Middle East, Southeast Asia, etc. The company is committed to building a complete supply chain of welding materials and providing customers with high standards of quality first and service first. The company sincerely recruits brand agents from various countries to negotiate business cooperation and open a new window for welding materials in the world .

FAQ

Hot Searches