- Product Details

- {{item.text}}

Quick Details

-

Voltage:

-

3PH~220V/380/415V~50HZ/60HZ

-

Dimension(L*W*H):

-

4978mmx2260mmx2375mm

-

Weight:

-

4886 KG

-

Warranty:

-

1 Year

-

After-sales Service Provided:

-

Engineers available to service machinery overseas

-

Certification:

-

ce

-

Name:

-

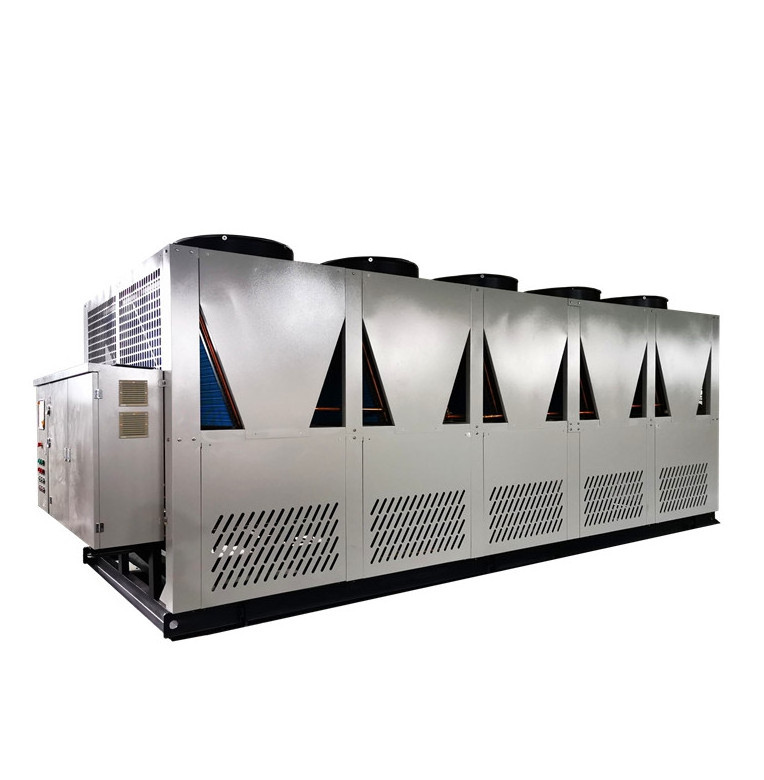

KCA water Chiller

-

Product name:

-

Water Cooled Chiller

-

Cooling capacity:

-

140TON-375TON

-

Compressor:

-

Horizontal semi-closed double screw compressor

-

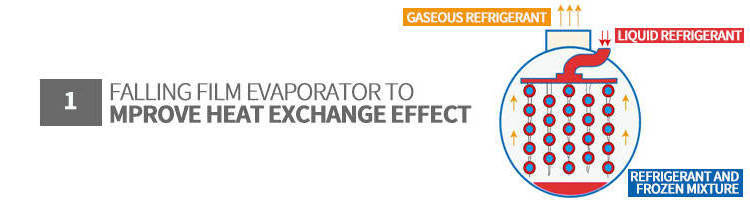

Evaporator:

-

shell tube type(failing film)

-

Application:

-

Industrial Cooling Solutions

-

Refrigerant:

-

R134a

-

Compressor type:

-

Semi-enclosed Twin-screw Compressor

Quick Details

-

Condition:

-

NEW100%

-

Place of Origin:

-

Jiangsu, China

-

Brand Name:

-

TOBEL

-

Voltage:

-

3PH~220V/380/415V~50HZ/60HZ

-

Dimension(L*W*H):

-

4978mmx2260mmx2375mm

-

Weight:

-

4886 KG

-

Warranty:

-

1 Year

-

After-sales Service Provided:

-

Engineers available to service machinery overseas

-

Certification:

-

ce

-

Name:

-

KCA water Chiller

-

Product name:

-

Water Cooled Chiller

-

Cooling capacity:

-

140TON-375TON

-

Compressor:

-

Horizontal semi-closed double screw compressor

-

Evaporator:

-

shell tube type(failing film)

-

Application:

-

Industrial Cooling Solutions

-

Refrigerant:

-

R134a

-

Compressor type:

-

Semi-enclosed Twin-screw Compressor

Product Description

Specification

Field of Application

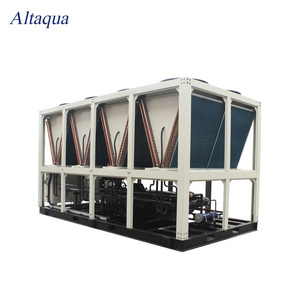

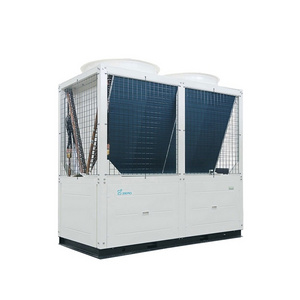

1.Air cooling type chiller products are widely used in the production and manufacturing industry of vacuum equipment.these air cooled chillers are mostly used in two groups of compressor heads,which can be used alone or in common use.the air-cooled chiller can meet the production requirements of high quality vacuum equipment,such as molecular pump,small vacuum coating machine and so on.All the production requires air-cooled chillers to provide professional refrigeration.

2.The air cooling water chiller also has many applications in the manufacture of medical machinery and equipment.the refrigeration environment provided by the cold water chiller is more conducive to the production of medical equipment.therefore,air-cooled chiller products have become the ideal matching equipment for medical laser equipment.at the same time,aie-cooled chiller products are also wodely used in atomic absorption spectrometry,fermentation equipment,reaction kettle,elctrophoresis apparatus and other feilds.

PRODUCT FEATURES

1.Primary pump variable flow(VPF) on the side of evaporator

the primary pump variable flow rate(VPF) is used to reduce investment from pipeline connect (material,manpower),electrial services

and so on,thus greatly dsaving costs.energy saving is an important reason foe the owner to choose a pump variable flow system.the application of Trace 700,Trace system analyzerTM analysis software can determine whether a pump variable flow system can achieve the expected energy saving effect. as long as the water flow exceeds the minimum limit,the evaportor side of KCA type chiller can bear 50% of water flow reduction.the advanced control logic of the CH530 cntroller can make the evaporator withstand the maximum flow rate of 10% per minute.at the same time,the water temperature deviation is precisely controlled at ‡0.28C°.for the system enargy saving needs.when the evaporator measured the water temperature deviation at ±1.1C°,the rate of change of flow per minute can be high as 30%.

1.Primary pump variable flow(VPF) on the side of evaporator

the primary pump variable flow rate(VPF) is used to reduce investment from pipeline connect (material,manpower),electrial services

and so on,thus greatly dsaving costs.energy saving is an important reason foe the owner to choose a pump variable flow system.the application of Trace 700,Trace system analyzerTM analysis software can determine whether a pump variable flow system can achieve the expected energy saving effect. as long as the water flow exceeds the minimum limit,the evaportor side of KCA type chiller can bear 50% of water flow reduction.the advanced control logic of the CH530 cntroller can make the evaporator withstand the maximum flow rate of 10% per minute.at the same time,the water temperature deviation is precisely controlled at ‡0.28C°.for the system enargy saving needs.when the evaporator measured the water temperature deviation at ±1.1C°,the rate of change of flow per minute can be high as 30%.

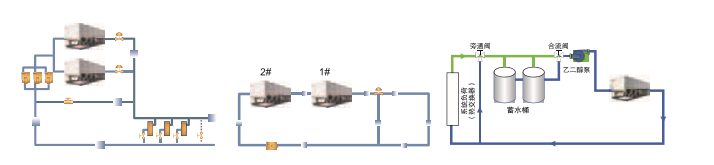

2.Tandem arrangement

the water chiller with a series arrangement is more efficient than the parallet unit.because the system has a higher water cooler in and out of the temperature difference,it can effectively reduce the design temperature and design flow of the frozen water,thus saving the cost of installation and operation.the excellent performance of the screw compressor can effectively support evaporator side energy saving design.figure 4 is a plan for each chiller to achieve the set value of the system design.if the cooling load is less than 50% of the cooling capacity of the system,any chiller can meet the demand.with the increase of the system load,the 2#unit tries to achieve the set point of the temperature of the outlet water of the chiller water and takes full load operation.the 1#unit will reduce the effluent temperature from 2#unit to the setting value of the system design. stagger the set point of the unit is another effective control method,that is ,1#unit with priority load.if the cooling load is less than 50% system cooling capacity,the 1#unit can fully meet the cooling capacity requirements.with the increase of system load,the 2# unit starts to run to meet the load that 1# unit can not meet.

the water chiller with a series arrangement is more efficient than the parallet unit.because the system has a higher water cooler in and out of the temperature difference,it can effectively reduce the design temperature and design flow of the frozen water,thus saving the cost of installation and operation.the excellent performance of the screw compressor can effectively support evaporator side energy saving design.figure 4 is a plan for each chiller to achieve the set value of the system design.if the cooling load is less than 50% of the cooling capacity of the system,any chiller can meet the demand.with the increase of the system load,the 2#unit tries to achieve the set point of the temperature of the outlet water of the chiller water and takes full load operation.the 1#unit will reduce the effluent temperature from 2#unit to the setting value of the system design. stagger the set point of the unit is another effective control method,that is ,1#unit with priority load.if the cooling load is less than 50% system cooling capacity,the 1#unit can fully meet the cooling capacity requirements.with the increase of system load,the 2# unit starts to run to meet the load that 1# unit can not meet.

3.Ice storage application

In addition to conventional air conditioning conditions,the KCA unit can meet the operational requiements of ice storage after ce making.it mainly uses the lower cost of electricity at night to make ice,thereby effectively reducing the operating cost of unit.besides the ice making inthe evening,the KCA unit can meet the normal cooling load requirements during the daytime with high effeciency.the optimized control logic of the CH530 controller enables the unit to aotomatically switch betwwen two operating modes,which greatly improves the operation efficiency.the ice storage system can operate in six different modes:

1)cold water cooler provides comfortable cooling mode

2)ice provides a comfortable cooling mode

3)cold water machine and ice provide cozy cooling mode together.

4)freezing ice storage tank model

5)ice storage tank mode when required for comfortable cooling

6)closingmode

Annual refrigeration:after adding low temperature components,the KCA unit can normally refrigerate at -18C° ambient temperature to meet the user's annual refrigeration needs.

In addition to conventional air conditioning conditions,the KCA unit can meet the operational requiements of ice storage after ce making.it mainly uses the lower cost of electricity at night to make ice,thereby effectively reducing the operating cost of unit.besides the ice making inthe evening,the KCA unit can meet the normal cooling load requirements during the daytime with high effeciency.the optimized control logic of the CH530 controller enables the unit to aotomatically switch betwwen two operating modes,which greatly improves the operation efficiency.the ice storage system can operate in six different modes:

1)cold water cooler provides comfortable cooling mode

2)ice provides a comfortable cooling mode

3)cold water machine and ice provide cozy cooling mode together.

4)freezing ice storage tank model

5)ice storage tank mode when required for comfortable cooling

6)closingmode

Annual refrigeration:after adding low temperature components,the KCA unit can normally refrigerate at -18C° ambient temperature to meet the user's annual refrigeration needs.

Customer Photos

Packing & Delivery

Hot Searches