- Product Details

- {{item.text}}

Quick Details

-

Model Number:

-

s-01

-

Material:

-

Material

-

Feature:

-

soundproof,Anti-collision

-

Size:

-

Universal,but can be customized as well

-

Colors:

-

black

-

Shape:

-

can be customized

-

Packing:

-

Carton Box

-

Specific gravity:

-

1.2 to 1.35 g/cm³

-

Temperature range:

-

-40°C -120°C

-

Manufacturing Process:

-

Rubber extrusion, hot air vulcanization, the mixing process

-

Tolerance:

-

RMA Standard Cross-sectional Tolerance E2, or per request

Quick Details

-

Processing Service:

-

Cutting

-

Place of Origin:

-

Shandong, China

-

Brand Name:

-

SEASHORE

-

Model Number:

-

s-01

-

Material:

-

Material

-

Feature:

-

soundproof,Anti-collision

-

Size:

-

Universal,but can be customized as well

-

Colors:

-

black

-

Shape:

-

can be customized

-

Packing:

-

Carton Box

-

Specific gravity:

-

1.2 to 1.35 g/cm³

-

Temperature range:

-

-40°C -120°C

-

Manufacturing Process:

-

Rubber extrusion, hot air vulcanization, the mixing process

-

Tolerance:

-

RMA Standard Cross-sectional Tolerance E2, or per request

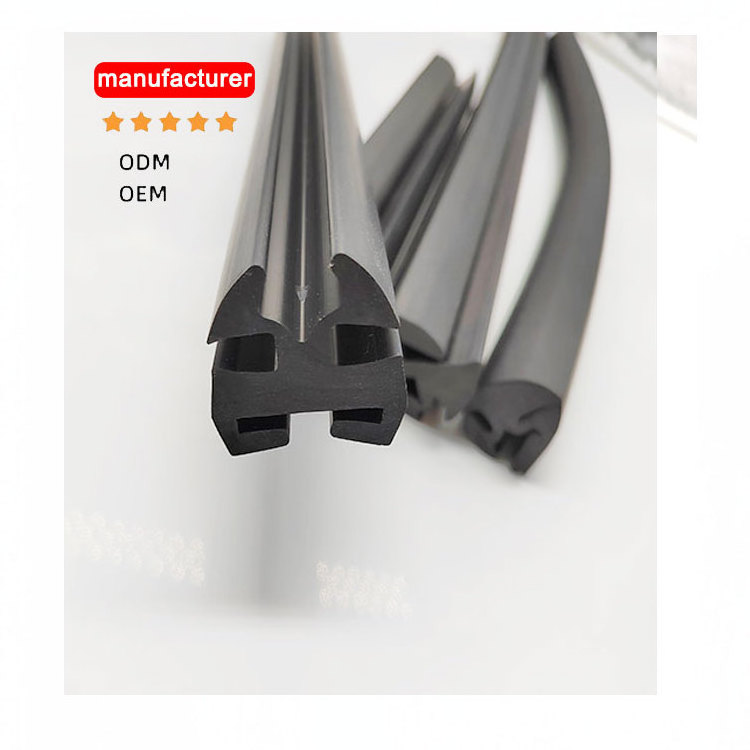

China EPDM windshield boat window rubber seal

Product Description

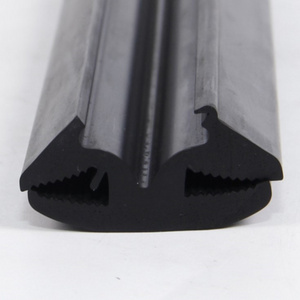

The windshield rubber seal for automotive is made of EPDM rubber and foam compound materials. It is an essential component installed in the windshield for automobile and industrial electrical industries. The universal windshield rubber seal is highly versatile. And it is suitable for a vast majority of vehicles. So that requires rubber seal strips to shield against heat, wind, dust, noise, impact, corrosion, weathering, aging, etc. We can manufacture universal weatherstripping for cars of different sizes and shapes to meet your expectations.

|

Material

|

EPDM and TPE compound rubber material

|

|

Color

|

Black, or available color on request

|

|

Hardness (Shore A)

|

70 ±5 as standard or per request

|

|

Specific gravity

|

1.2 to 1.35 g/cm³

|

|

Temperature range

|

-40°C – 120°C

|

|

Tensile strength

|

10MPA

|

|

Manufacturing Process

|

Rubber extrusion, hot air vulcanization, the mixing process

|

|

Tolerance

|

RMA Standard Cross-sectional Tolerance E2, or per request

|

GOOD RAW MATERIAL

The product uses new rubber raw materials Good flexibility, no odor durable.

Available in various sizes ,Support non-standard customization Special-shaped mold opening.

GOOD INSULATION

Elastic insulation,good wear resistance.

could stop air, water and dust enter the machine system, which could protect the machine or parts to be healthy and working well.

Product Advantages

* Good Sealing And Insulation Properites

Excellent resistance to weathering, sound, water, dust, ozone, radiation, hazardous chemicals, corrosion, abrasion, etc.

Effectively insulate outdoor wind noise or road noise, reduce vibration during driving.

* High Physically Stable Properites

Heat resistant and remain flexible and durable even at lower temperature.

High tear strength, low compression set, no shrinkage or cracking.

* Ecofriendly And Energy-saving Properties

Recyclable, odorless and non-toxic rubber materials.

Keep cold air in summer and warm air in winter, more enengy-efficient.

Excellent resistance to weathering, sound, water, dust, ozone, radiation, hazardous chemicals, corrosion, abrasion, etc.

Effectively insulate outdoor wind noise or road noise, reduce vibration during driving.

* High Physically Stable Properites

Heat resistant and remain flexible and durable even at lower temperature.

High tear strength, low compression set, no shrinkage or cracking.

* Ecofriendly And Energy-saving Properties

Recyclable, odorless and non-toxic rubber materials.

Keep cold air in summer and warm air in winter, more enengy-efficient.

Benefits of Universal Windshield Rubber Seal Strip For Automotive

Effectively insulate wind and road noise during driving, take your driving experience to a new level.

Prevent leakage of air-conditioning in summer and keep warm in winter.

Simple installation, durable in use.

Prevent objects falling off into the gap on the console of the vehicle.

Prevent water from seeping into the vehicle on rainy or snowy days.

Prevent debris from entering the gap of the front or rear windshield.

Ecofriendly and safe rubber material, meet your expectations in multiple applications.

Easy to clean and recyclable.

Decsigned for decorative and functional purpose.

Provide long-term shield against impact and wear and tear.

Highly versatile and for for a variety of vehicle models.

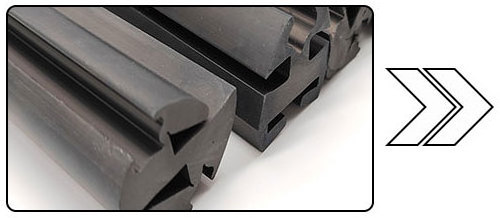

Qingdao Seashore Industrial Co., Ltd is a joint-stock private enterprise that produces seal strips and seals for automobiles, doors and windows, construction machinery, ships, and rails. Since its establishment in 2000, it has been committed to the rubber and plastic sealing and shock absorption industry. The company’s main products include rubber, plastic extrusion seal strip and seals, door and window seals, automotive rubber seal strip, marine hatch seals, waterstop, rubber tubes, etc., and also provides sealing and vibration damping systems solutions for global customers.

Our Seashore company is headquartered in Licang District, Qingdao, and has a production base in Jimo District. The company has more than 100sets rubber and plastice equipments such as rubber extrusion lines, plastic extrusion lines, three (four) composite microwave vulcanization production lines, salt bath vulcanization production lines, steel edge rubber waterstop vulcanization production line etc. Our company’s R&D center is equipped with Mooney viscometer, rotorless vulcanizer, tensile testing machine, density tester, hardness tester, aging test chamber, ozone resistance test chamber, low-temperature brittleness tester Testing equipment such as test chambers and a complete set of chemical material analysis experimental instruments can conduct chemical analysis of purchased raw materials and test the performance of finished products.

FAQ

Q1: How soon can I get a precise quotation for custom rubber extrusion?

Please send us your inquiry by email or Alibaba TM message. Once we confirm the design (Feature details with parameters),material, color, qty, we can provide quotation within 24 HOURS.

Q2: Can I get a free sample, how long will it take?

a. For standard products we have in stock, YES for free sample, but the express fee will be charged in advance. Mostly, it takes 3-10 days.

b. For custom products, sample fee is determined by the detailed sample requirements. Normally, it takes 7-15 days.

Q3: Can you make custom parts based on my sample?

Yes, you can send the sample to us by express and we will evaluate the sample, scan the features and draft 3D drawing for production.

Q4: What does your OEM service include?

We follow up your request from the design idea to the mass production.

1. You can provide 3D drawing to us, then our engineers and production teams evaluate the design and quote you the precise cost.

2. If you don’t have 3D drawing, you can provide 2D drawing or draft with features details with full dimensions, we can draft 3D drawing for you with fair charge.

3. You can also customize Logo on the product surface, package, color box or carton.

4. We also provide assembly service for the OEM parts.

Hot Searches