- Product Details

- {{item.text}}

Quick Details

-

Heating Model:

-

directly heating

Quick Details

-

Place of Origin:

-

Henan, China

-

Output:

-

Fuel oil

-

Work Model:

-

batch-type

-

Heating Model:

-

directly heating

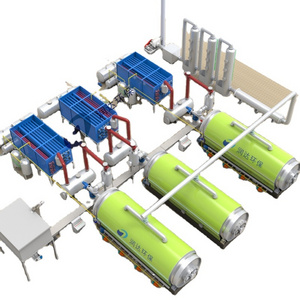

waste plastic pyrolysis oil refining system

The advantages of waste tire pyrolysis plant:

a) the material of the reactor is 16mm boiler plate,and it’s more useful than the 12mm and 14mm one.

b)The cooling tubes we use is 10tubes,the diameter is 220mm,no jamming concerns and easy to maintenance.

c)The horizontal cooling pool without electricity machine can save more electricity than vertical one.

d)3 parts to clean the waste in the gas,no pollution to the environment.

e)Recycling the waste gas as fuel to burn after 2hours.

f)Big draft fan take away the smoke slao keep the temperature in the reactor.

g)With safety valve to control the pressure to make sure the safety.

The principle introduction of

waste tire pyrolysis plant

:

Pyrolysis is thermochemical decomposition of tyre and plastic polymer, since waste tyre and plastic are long chain polymers containing more than 50,000 carbon atoms. The process will require an initial fuel source of coal, wood or oil. Oil gas produced flows through several successive condensers where the gas is cooled and oil gas is condensed into oil.

Process description of

waste tire pyrolysis plant

:

Oil equipment is suitable for degumming,de-acidifying,decoloring and deodorization treatment Animal oil refinery equipment.

1.Oil equipment is suitable for degumming, deacidification, decoloring

and deodorization treatment. According to the client, the products come up to

the high grade cooking oil.

The first and the second class of the state standard of china.

2. Main machines: Lye tank,hot water tank,water Ejector,water and steam

Ejector, Steam header, Soap stock

Vessel, refining tank,decolorizing tank, deodorizing vessel, oil separating tank,

clay tank,filter, Alkali dissolving tank, decolorizing oil tank, oil pump, etc.

3. Flow chart: rude oil ---- neutralize ---- degumming ---- decoloring ---- deodorizing ---- cooling ---- winterization ---- final oil

Capacity:2T-20T/D crude oil

4. Process:physical refining,chemical refining

5. Refining ways: batch type,semi-continuous

6. Raw materials:peanut oil,peanut oil,soybean oil,sunflower oil,rapeseed oil,

cottonseed oil,maize oil,rice bran oil,tea seed oil, sesame oil, castor oil, tung oil, walnut oil, pine nut oil, grape stone kernel, sallow thorn oil, fish oil, lard, tallow, chicken fat.

7. Product oil grade(kinds):

First, second, third,fourth grade oil of national standards,blend oil,special

fragrance oil and faint scent oil.

8. The price of winterization part covers 40% of the total price.

3.Technical parameters:

| NO. | ITEM | Technical Parameter |

| 1 | Suitable Raw Materials<=5cm | Small pieces of Waste tyre,rubber,waste plastic<=10cm |

| 2 | Operating Mode | Fully Continuous Opreation |

| 3 | Structure | Horizontal Type |

| 4 | Loading and discharging | Fully automatic feeding and discharging under high temperature at same time |

| 5 | Capacity(24h) | 10-30 Mt |

| 6 | Work Pressure | Slightly Negative Pressure |

| 7 | Oil Yield of tyres | 40%-45% |

| 8 | Reactor Rotation Speed | 1R/M |

| 9 | Power | 50-60kw/h |

| 10 | Cooling Method | Cycle water |

| 11 | Type of Drive | Sprocket Wheel |

| 12 | Heating Method | Hot Air |

| 13 | NoisedB(A) | <=85 |

| 14 | Main Reactor Weight(Mt) | 25 Mt |

| 15 | Total Weight(Mt) | 30-40Mt |

| 16 | Installation Space Required | 48 m* 20 m |

| 17 | Manpower | 2/shift |

Packing Details: in wooden packaging ,according to customer's requirements