- Product Details

- {{item.text}}

Quick Details

-

Model Number:

-

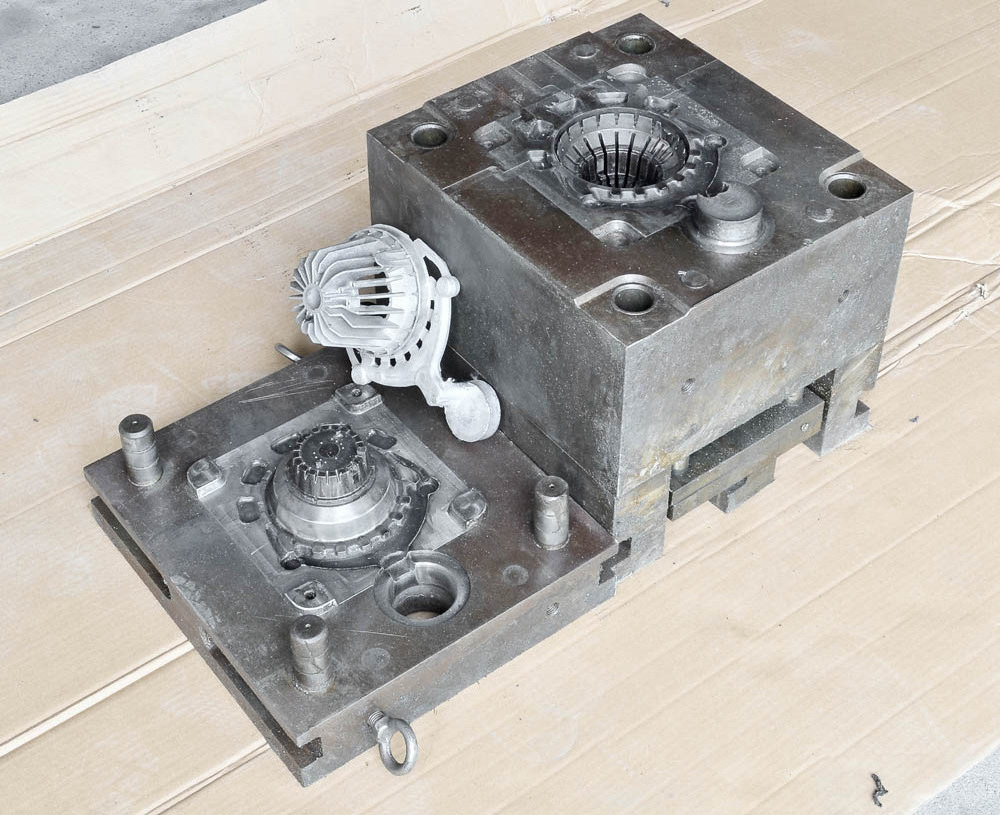

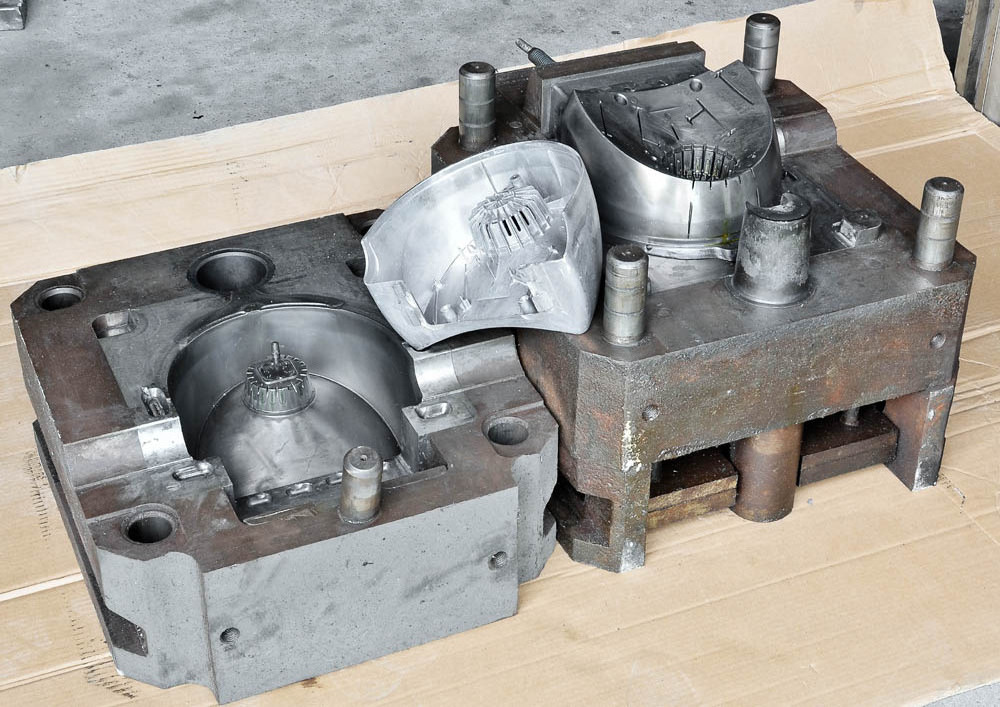

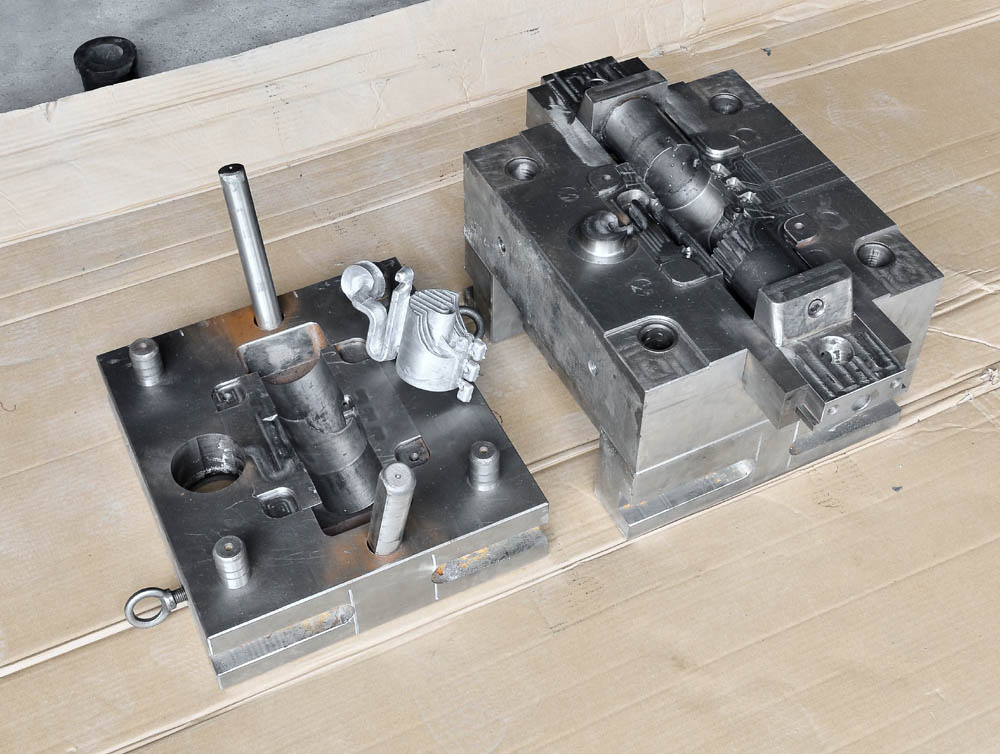

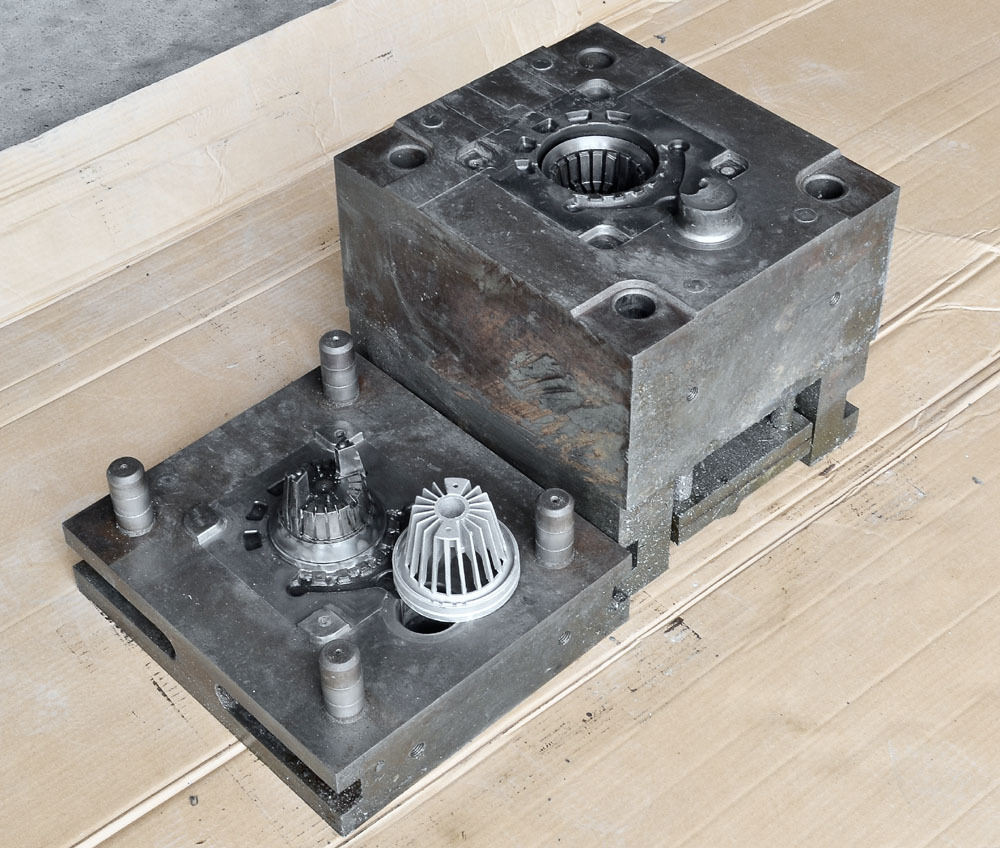

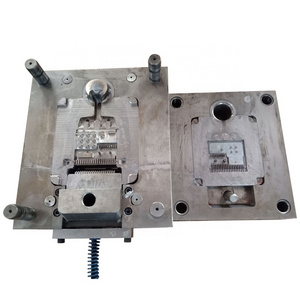

Zinc alloy product die casting mould

-

Name:

-

Zinc alloy product die casting mould

-

Material:

-

H13 steel core and 45 steel frame

-

Appilication:

-

mould for aluniumium alloy and zinc alloy

-

standard:

-

iso9001-2012

-

drawing file:

-

IGS , STEP , SLD , X_T . DXF .DWG. SAT. STL

-

Surface Treatment:

-

Polishing, Painting, Powder coating, or according your requests

-

Service:

-

OEM &ODM service

-

packing:

-

wood pallet

-

Dimension:

-

According to drawings or samples

Quick Details

-

Shaping Mode:

-

Die Casting

-

Place of Origin:

-

Zhejiang, China

-

Brand Name:

-

Hoteng

-

Model Number:

-

Zinc alloy product die casting mould

-

Name:

-

Zinc alloy product die casting mould

-

Material:

-

H13 steel core and 45 steel frame

-

Appilication:

-

mould for aluniumium alloy and zinc alloy

-

standard:

-

iso9001-2012

-

drawing file:

-

IGS , STEP , SLD , X_T . DXF .DWG. SAT. STL

-

Surface Treatment:

-

Polishing, Painting, Powder coating, or according your requests

-

Service:

-

OEM &ODM service

-

packing:

-

wood pallet

-

Dimension:

-

According to drawings or samples

|

Product

|

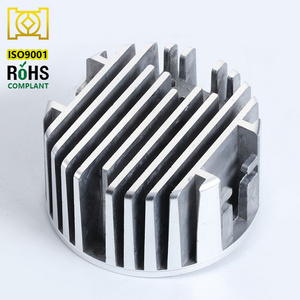

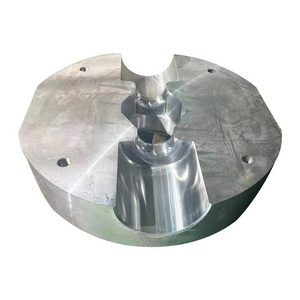

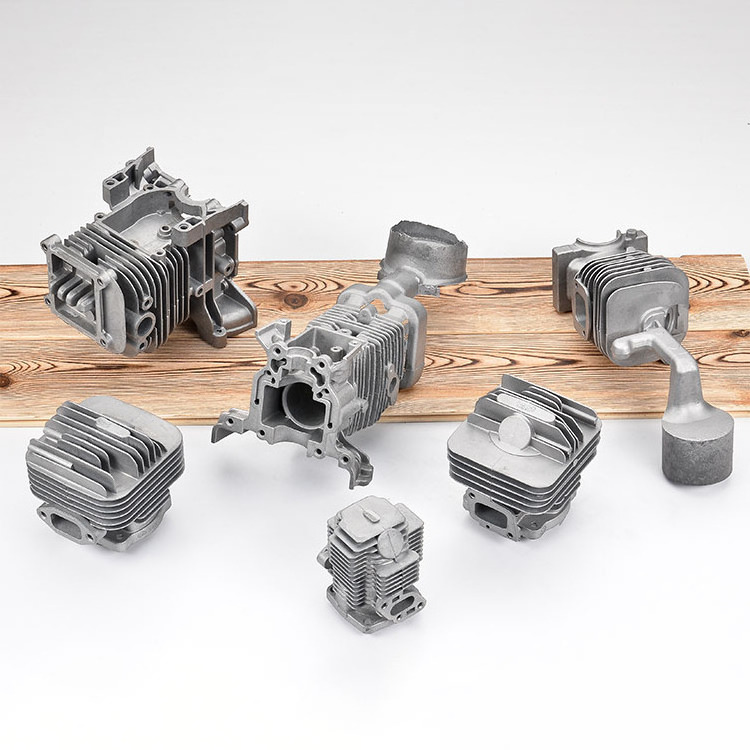

Aluminum & Zinc die casting parts /Moulds/ Auto parts/Motocycle parts

|

|

Machine

|

LK Brand Die casting machine 120 ton/280 ton/400 ton/500 ton/800 ton/1250 ton

|

|

Material

|

Aluminum alloy ADC10 . ADC12 . A 360 . A380 .

|

|

Process

|

Drawing & Samples→Mould making→ Die casting → Deburring →Drilling and threading → CNC Machining → Polishing → Surface treatment→ Assembly → Quality inspection → Packing →Shipping

|

|

Surface treatment

|

Polishing, Sandblasting, Painting, Powder coating, Galvanizing, Chrome plating

|

|

Application

|

Led light housing & Led Heatsink

|

|

|

Auto & motocyle & bicycle parts

|

|

|

Furniture accessories

|

|

|

Power tool housing

|

|

|

Pump housing

|

|

|

Mechanical parts

|

|

Drawing file

|

IGS , STEP , SLD , X_T . DXF .DWG. SAT. STL .

|

|

ISO Cetificate

|

ISO9001-2012

|

|

Our advantage

|

More than 10 years of experience in die casting field .

With talented and experienced engineers

|

About Us

Payment & Shipping

Q1: Are you a manufacturer or trading company?

A1: Hoteng is an OEM die casting and mould making factory

Q2:

What’s the

Process?

A2: Drawing & Samples→Mould making→ Die casting → Deburring →Drilling and threading → CNC Machining → Polishing → Surface treatment→Assembly → Quality inspection → Packing →Shipping

Q3:

What’s the

Surface treatment?

A3: Polishing, Sandblasting, Painting, Powder coating, Galvanizing, Chrome plating.

Q4:

What’s the

Drawing file?

A4: IGS , STEP , SLD , X_T . DXF .DWG. SAT. STL .

Q5: What’s the lead time of production samples?

A5: Usually 5 days after mould's done.

Homepage

Hot Searches