- Product Details

- {{item.text}}

Quick Details

Quick Details

-

Technique:

-

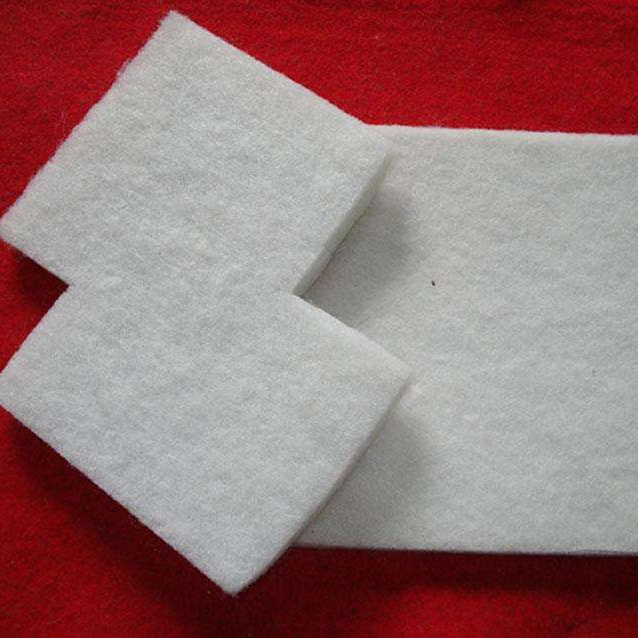

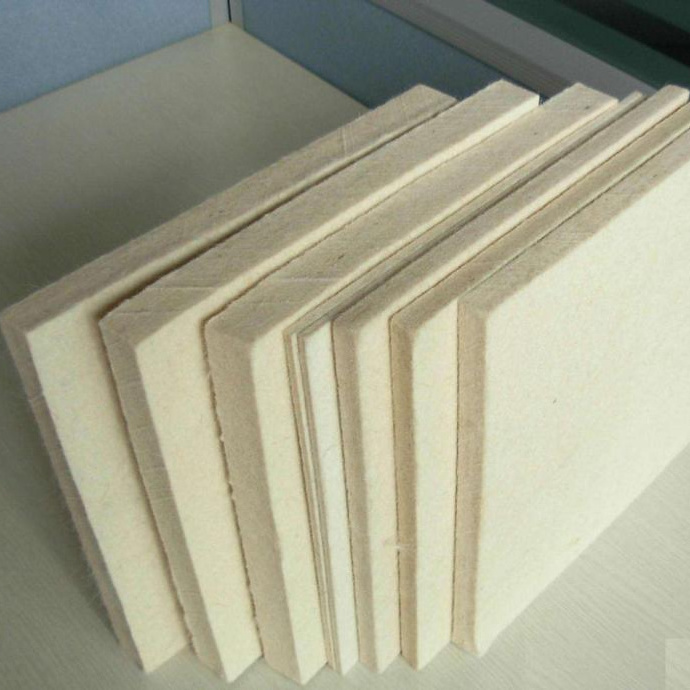

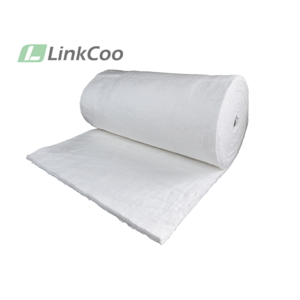

Needle Mat

-

Place of Origin:

-

Shandong, China

Silica fiberglass needled mat

Silica fiberglass is inorganic fiber that contents more than 96% of SiO2, it’s resistant to high temperature, soft point 1700℃, long term service temperature 900℃, and it can work 10 minutes at 1450℃ and keeps good state at 1600℃ for 15 seconds. For it’s properties of chemical stability, high temperature resistance and obtain resistance, it widely used in aviation and aerospace, metallurgy, chemical, building material and fire fighting industry, etc...

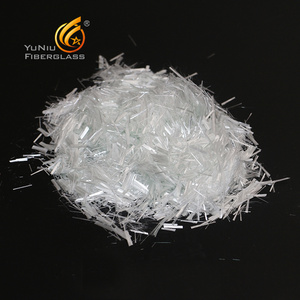

We have silica fiberglass products ate available in forms if needled mat, fabric, scrim, staple yarn, chopped strand, cord, etc.

Properties

- SiO2≥96%

-Soft point nearly 1700℃, long-period service at 900℃

-Low thermal conductivity

-Good chemical stability

-Good electrical insulation

-Low thermal shrinkage

-Non-asbestos product without pollution

-Good process performance

Application

-High temperature resistant, insulation and sealing maerial

-High temperature ablation resistant material

-Fireproof material (for fireproof protective clothe, fireproof curtain, fire blanket)

-Dust collecting in media if high temperature gas and filtration in media if high temperature liquid

-Filter for molten metal

-Distinguisher, insulation material, filtration of automobile and motorcycle

|

Style |

Thickness

|

Width

|

Weight

|

Breaking strength

|

thermal shrinkage % |

SiO2 content

|

remark |

|

|

Warp |

Weft |

|||||||

|

J-SNM1/4” |

6.3 7.9 |

91.5-92 |

890±80 |

≥15 |

≥10 |

≤13.0 |

≥96 |

Base mat |

|

J-SNM1/2” |

12.7 15.9 |

91.5-92 |

2000±200 |

≥40 |

≥20 |

≤13.0 |

≥96 |

Base mat |

|

J-SNM1” |

21-24 |

91.5-92 |

3660±360 |

≥80 |

≥40 |

≤13.0 |

≥96 |

Base mat |

|

remark test condition of thermal shrinkage 980℃ 30 minutes |

||||||||