Explore More Products

- Product Details

- {{item.text}}

Quick Details

-

Brand Name:

-

HF

-

Model Number:

-

1050/1060/1100/3003/5052

-

Application:

-

Decoration,roofing,ceiling,gutter,curtain wall

-

Width:

-

20-2400mm

-

Product Name:

-

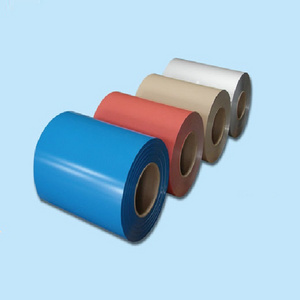

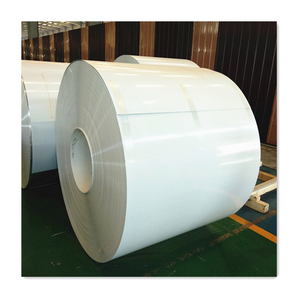

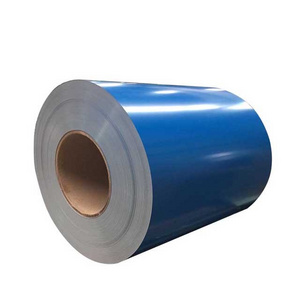

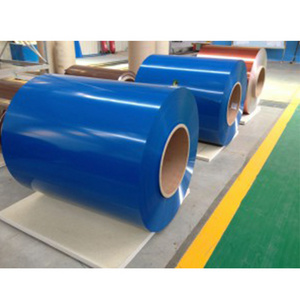

Color coated aluminum roll

-

Color:

-

as customers' request

-

Painting:

-

PE or PVDF

-

Surface treatment:

-

Mill finish,embossing, anodized, color coating, Polishing

-

Width of DC:

-

100-2600mm

-

Width of CC:

-

100-1700mm

-

Feature:

-

Mill Finish

-

Service:

-

ODM OEM

-

Standard:

-

Professional production standard

-

Sample:

-

Provide

Quick Details

-

Grade:

-

1000 Series

-

Tolerance:

-

±3%

-

Place of Origin:

-

Shandong, China

-

Brand Name:

-

HF

-

Model Number:

-

1050/1060/1100/3003/5052

-

Application:

-

Decoration,roofing,ceiling,gutter,curtain wall

-

Width:

-

20-2400mm

-

Product Name:

-

Color coated aluminum roll

-

Color:

-

as customers' request

-

Painting:

-

PE or PVDF

-

Surface treatment:

-

Mill finish,embossing, anodized, color coating, Polishing

-

Width of DC:

-

100-2600mm

-

Width of CC:

-

100-1700mm

-

Feature:

-

Mill Finish

-

Service:

-

ODM OEM

-

Standard:

-

Professional production standard

-

Sample:

-

Provide

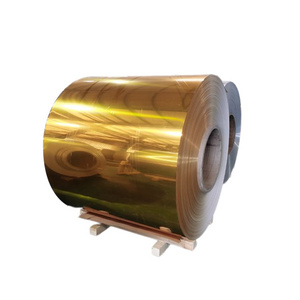

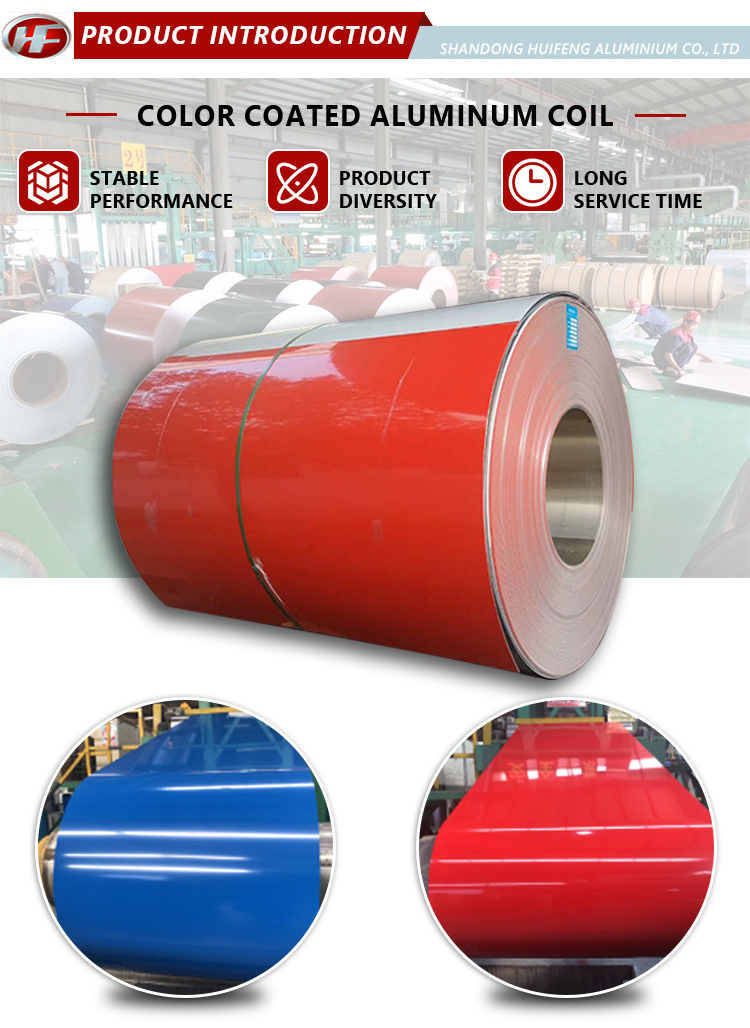

High Efficiency Mass Production Gold Brushed Coated Aluminum Gutter Coil 15 0.32 White Color Aluminum Coil For Curtain Wall

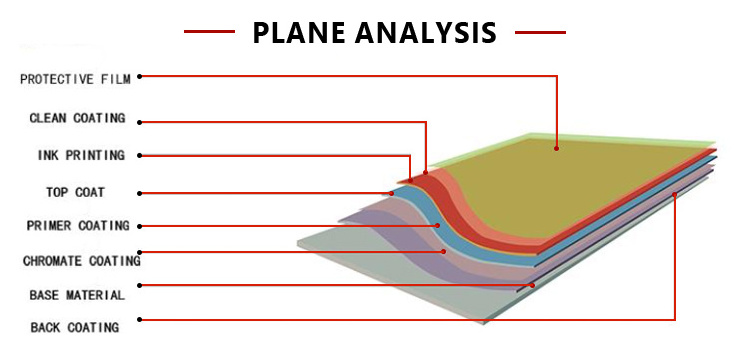

Color coated aluminum coil

is a salt with an excellent acid-resistant material. Coating to maintain a long light. It is an environmentally friendly, fire-resistant properties of the green and beautiful decorative.color coated aluminum coil are widely used in ACP,curtain panel honey comb panel,shutter,roofing and most of the decoration areas. We have introduced in most advanced computerized metal processing equipment, Pre-treatment by the German Henkel and Kenema Mittel, paint coatings using the PPG BECKER paint, PVDF perfluorocarbons can be divided into surface coatings, self-cleaning nano-Kang Wu fluorocarbon coating, coated polyester, acrylic coating.

It is produced by advanced roll coating process, with good PE coating and high performance aluminum coil. All the performance parameters have reached or far higher than the relevant national standards.

PVDF(fluorine-carbon) coating : made of fluorine carbon resin, pigment, ester solvent, after high temperature roasting and baking, the paint is solidified to dry film with super weather resistance. PVDF coating also can be classified as traditional PVDF and nanometer PVDF coating.

TEMPERATURE

RESISTANCE

The melting point of aluminum is 660 degrees, and the general temperature does not reach its melting point.

02

ENVIRONMENTAL

PROTECTION

Environmentally

friendly, non-toxic easy to recycle, in line with environmental protection requirements.

CORROSION

RESISTANCE

Due to its tight surface oxide film

it has strong adhesion, oxidation resistance and corrosion resistance.

04

SCRATCH

RESISTANT

High-quality aluminum, highhardness scratch resistance, surface hardness

equal to sapphire.

Specification

of aluminum coil

Alloy number:1060, 1070, 1100, 2A12, 2024, 3003,3004, 3105, 5052, 5083, 5754, 6061, 6063, 6082, 7075 etc

Temper:H32 H24 H16 H18 O H111 H112 T3 T351 T4 T42 T6 T651

Thickness:0.1-200mm

Width of DC:100-2600mm

Width of CC:100-1700mm

Length:coil

Surface treatment:Mill finish,embossing, anodized, color coating, Polishing

Alloy number:1060, 1070, 1100, 2A12, 2024, 3003,3004, 3105, 5052, 5083, 5754, 6061, 6063, 6082, 7075 etc

Temper:H32 H24 H16 H18 O H111 H112 T3 T351 T4 T42 T6 T651

Thickness:0.1-200mm

Width of DC:100-2600mm

Width of CC:100-1700mm

Length:coil

Surface treatment:Mill finish,embossing, anodized, color coating, Polishing

|

Item

|

Test Item

|

>Standard

|

National standard

|

Test Result

|

|

1

|

Color Difference

|

>ECCA T3

|

ΔE≤2.0

|

ΔE≤1.5

|

|

2

|

Gloss Difference

|

>ECCA T2

|

≤10

|

≤5

|

|

3

|

Coating Thickness

|

>ECCA T1

|

Min 14µm

|

≥16µm

|

|

4

|

Pencil Hardness

|

>ASTM D3363

|

≥HB

|

HB

|

|

5

|

T-bend

|

>ASTM D4145

|

≤3T

|

≤2T

|

|

6

|

Adhesion

|

>ASTM D3359

|

Grade 0

|

Grade 0

|

|

7

|

Impact

|

>ASTM D2794

|

≥20kg.cm

|

≥20kg.cm

|

|

8

|

Boiling water Resistance

|

>GB/T17748

|

2h no change

|

2h no change

|

|

9

|

Solvent Resistance

|

>ASTM D2248

|

200 times paint

remaining |

200 times paint

remaining |

|

10

|

Salt Resistance

|

>ASTM B117

|

720 hrs≤grade 1

|

720hrs≤grade 1

|

|

11

|

Dirt Resistance

|

>GB/T9780

|

≤5%

|

<5%

|

|

12

|

Color retaining

|

GB/T16259

|

600hrs △E≤2.0

|

△E≤2.0

|

|

13

|

Gloss weaken Level

|

|

600hrs ≤ grade 2

|

600hrs ≤ grade 2

|

|

14

|

Chalking

|

|

600hrs No Change

|

No Change

|

Shandong Huifeng aluminium Co., LTD.

restructured from state-run enterprise , located in China's "rose town "-PingYing county of Jinan city, covers an area of more than 600 acres, it has 3 production factory and a joint venture factory. The product range includes aluminum tube, aluminum rod, industry aluminum profiles, aluminum coils and plate. Aluminum extrusion equipment including 7500 tons, 3600 tons and 2800 tons extruder 1350 tons 1300 tons and 880 tons double-acting extruding machine, 800 tons reverse

extruding machine, 630 tons 500 tons extruding machine, tension straightening machine 11 rollers straighter, tube drawing mill,rod drawing machine, 400 KW vertical quench furnace and tube rolling mill production lines; Ancillary equipment including nitriding furnace, homogeneous furnace, and ageing oven, eight set of intermediate frequency induction furnace and oxidation ponds.Alloy including 1070 2024 2017 2011 2A21 2014 2A12 2618 3003 3004 3105 5052 5754 5083 6063 6061 6082 6005 7075 7A04 7005

7049 etcTemper: O T3 T4 T5 T6 T8 T651 T3511 etc. The aluminum coil equipment including 1850 mm hot rolling mill ,one sets of 1850 mm & two sets of 1450 mm cold rolling mill and 260 meters roller coating production line. We have passed the ISO9001, 2000 quality system authentication, and set up the professional testing laboratory, equipped with a spectrum analyzer, CNC tensile tester, high

magnification microscopy, hardness tester etc, with our qualified technical personnel together, to ensure the product quality completely meet customer's requirements.Meeting buyer's demands is always our objects. Integrated products range give us more advantages. Shandong Huifeng aluminium Co., Ltd will always insist on "provide best products satisfying customers, quick response and full service

extruding machine, 630 tons 500 tons extruding machine, tension straightening machine 11 rollers straighter, tube drawing mill,rod drawing machine, 400 KW vertical quench furnace and tube rolling mill production lines; Ancillary equipment including nitriding furnace, homogeneous furnace, and ageing oven, eight set of intermediate frequency induction furnace and oxidation ponds.Alloy including 1070 2024 2017 2011 2A21 2014 2A12 2618 3003 3004 3105 5052 5754 5083 6063 6061 6082 6005 7075 7A04 7005

7049 etcTemper: O T3 T4 T5 T6 T8 T651 T3511 etc. The aluminum coil equipment including 1850 mm hot rolling mill ,one sets of 1850 mm & two sets of 1450 mm cold rolling mill and 260 meters roller coating production line. We have passed the ISO9001, 2000 quality system authentication, and set up the professional testing laboratory, equipped with a spectrum analyzer, CNC tensile tester, high

magnification microscopy, hardness tester etc, with our qualified technical personnel together, to ensure the product quality completely meet customer's requirements.Meeting buyer's demands is always our objects. Integrated products range give us more advantages. Shandong Huifeng aluminium Co., Ltd will always insist on "provide best products satisfying customers, quick response and full service

Q1.CAN WE GET YOUR FREE SAMPLES?

Yes, you can. Our Samples are free for the customers. But the freight for express is on the buyer's

account

account

Q2.WHEN CAN I GET THE QUOTATION?

Within 24 hours after getting the inquiry. If you are very urgent to get the price please call us

to give complete specifications and the price will be sent soon

to give complete specifications and the price will be sent soon

Q3.HOW LONG IS YOUR DELIVERY TIME?

Usually within 15-30 working days after payment, mainly according to the quantity.

Q4.WHAT IS YOUR SHIPPING WAY?

We will help you to choose the best shipping way according to your detailed requirements.By sea, by air, or by express, by train, etc.

Q5.HOW DO YOU CONTROL THE QUALITY?

We have our own testing lab to ensure accuracy and speed. The can production process includes the following very important inspection steps: Video microscopemetrology (non-contact measurement), Leak testing, Light testing,Camera inspection Enamel testing.

Hot Searches