- Product Details

- {{item.text}}

Quick Details

-

Blade Length (mm):

-

3300 mm

-

Backgauge Travel (mm):

-

20 - 600 mm

-

Throat Depth (mm):

-

120 mm

-

Brand Name:

-

KINGWELL

-

Power (kW):

-

7.5 kW

-

Weight (KG):

-

5500 KG

-

Place of Origin:

-

Jiangsu, China

-

Voltage:

-

By customer`s requirement

-

Dimension(L*W*H):

-

3880*1650*1800mm

-

Type:

-

Shearing Machine

-

Application:

-

Industrial Metal Cutting

-

Cutting material:

-

Metal Stainless Steel Carbon Steel Aluminum

-

Cutting mode:

-

Swing Beam Cutting Machine

-

Controller:

-

CNC

-

Color:

-

Blue / Red

-

Blade:

-

Alloy Steel

-

Cutting thickness:

-

0-6mm Carbon Steel

-

Cutting width:

-

3200mm

-

Electrical Equipment:

-

Siemens Germany

Quick Details

-

Max. Cutting Width (mm):

-

3200

-

Max. Cutting Thickness (mm):

-

6 mm

-

Shearing Angle:

-

1.5°

-

Blade Length (mm):

-

3300 mm

-

Backgauge Travel (mm):

-

20 - 600 mm

-

Throat Depth (mm):

-

120 mm

-

Brand Name:

-

KINGWELL

-

Power (kW):

-

7.5 kW

-

Weight (KG):

-

5500 KG

-

Place of Origin:

-

Jiangsu, China

-

Voltage:

-

By customer`s requirement

-

Dimension(L*W*H):

-

3880*1650*1800mm

-

Type:

-

Shearing Machine

-

Application:

-

Industrial Metal Cutting

-

Cutting material:

-

Metal Stainless Steel Carbon Steel Aluminum

-

Cutting mode:

-

Swing Beam Cutting Machine

-

Controller:

-

CNC

-

Color:

-

Blue / Red

-

Blade:

-

Alloy Steel

-

Cutting thickness:

-

0-6mm Carbon Steel

-

Cutting width:

-

3200mm

-

Electrical Equipment:

-

Siemens Germany

QC12Y-6x3200 Hydraulic Metal Plate Shearing Machine For Sale

Pro duct Application

QC12Y hydraulic swing beam shearing machine is the sheet metal industry under the cutting tool, Widely used in industrial machinery, metallurgical industry, automobile, shipbuilding, electrical appliances, engineering equipment, sheet metal processing, steel pipe welding, electronic industry, aerospace industry, agricultural machinery manufacturing, dining furniture machinery industry.

|

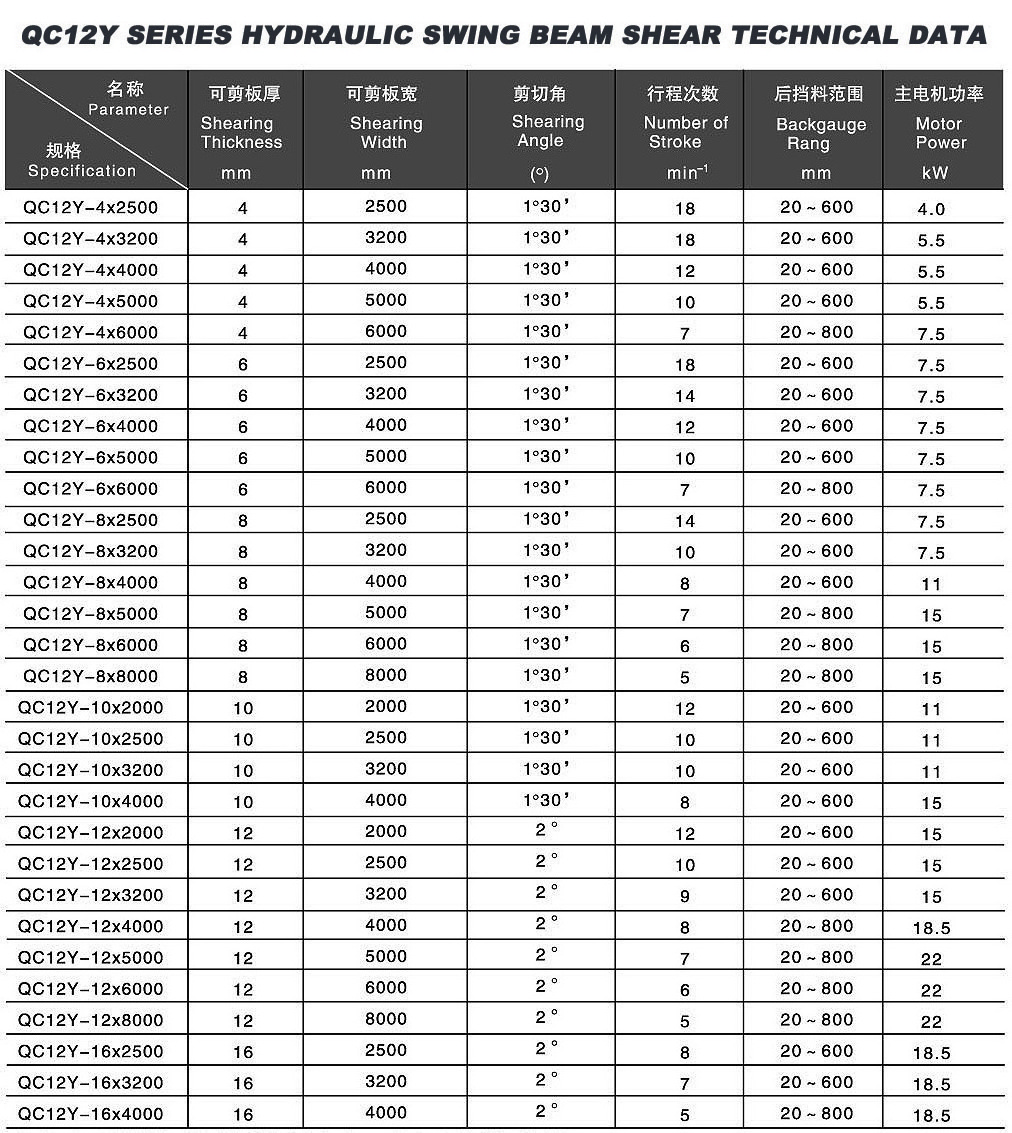

TECHNICAL PARAMETER

|

|

|

|

|||

|

1

|

Machine Model

|

QC12Y-6X3200

|

|

|||

|

2

|

Max Cutting Thickness

|

mm

|

6

|

|||

|

3

|

Max Cutting Length

|

mm

|

3200

|

|||

|

4

|

Strength

o

f shear

ing sheet

|

Mpa

|

ób≤450

|

|||

|

5

|

Shearing Angle

|

|

1.5°

|

|||

|

6

|

Max Length of Back Gauge

|

mm

|

20-600

|

|||

|

7

|

Stroke Number

|

n/min

|

14

|

|||

|

8

|

Blade Length

|

mm

|

3300

|

|||

|

9

|

Height of Worktable

|

mm

|

800

|

|||

|

10

|

Main Motor Power

|

KW

|

7.5

|

|||

Performance characteristics

1. Totally European design, streamlined looking. Monoblock steel welding frame and stress relief process by Annealing treatment.

2. This hydraulic shearing machine is a Swing Beam Action machine which is produced in a variety of cutting lengths and capacity options.

3. Triple support rolling guide to eliminate gaps of support and enhance shearing quality.

4. Sliding balls inserted into work table allowing material to be easily moved to the cut position and squaring arm.

5. All seals in cylinder is imported, the most famous brand, good quality and high performance

6. Overload overflow protection is outfitted to hydraulic system, which can assure no leakage

7. The distance of the backgauge is adjusted by the motor.

8. Digital display device for distance of back gauge and shearing times available.

9. Adopt handwheel to rapidly and accurately adjust the blade clearance

10. Adopt integrated hydraulic system, more reliable and easy for maintenance. The hydraulic system consists of motor, oil pump and valve groups and it is installed at the top of the oil box.

11. Hydraulic drive, return of knife beam is smooth and prompt by nitrogen cylinder.

12. Humanistic concern security design in all details and also the scientific details through KINGWELL standard.

Standard Equipment

2. High quality, hardened and grinded top and bottom blades. Top blades with two cutting edges and bottom blades with four cutting edges.

3. Counter of Strokes, Cutting Length Adjustment

4. Hydraulic and Electrical overload protection

5. Squaring Arm and Front Support Arms

6. Built-in Spring Pressure Cylinder

7. SIEMENS Motor or Chinese High Quality Motor (Because SIEMENS motor made in China has long delivery period, if the special voltage , we will not use SIEMENS unless the client can accept the long delivery period for machine also. Mostly the normal voltage , the delivery is 30-40 working days for motor. We also use a lot of Motor named CHINA HANNENG, its quality has been proved with several years working. )

8. Germany Bosch Rexroth Hydraulic System or CHINA Top Level Youtong Hydraulic System.

9. USA SUNNY Hydraulic Gear Pump or CHINA Shanghai YONGMING High Quality Hydraulic Gear Pump which is used for Chinese Aircraft Industry.

10. JAPAN VALQUA sealing parts .

11. Germany JS tubing connector

12. Germany SIEMENS or France SCHNEIDER Main Electric Elements.

13. HIWIN Ball screws & Polished rod

14. Estun E21S NC system or other NC controller system.

You can also choose other models from below sheet by your requirement.

We are involving in the technique innovation and technical improvement with the market, we have been offering, and will continue to supply alternatives quality assured metal processing machines.

In the past 20 years, we have established business relationships with customers from more than 40 countries, including Australia, Southeast Asia, Europe, Middle East , South America, North America, Africa and so on.

We here thanks all your trust. Your encouragement is the driving force of our progress.

Q2. How long about your machine guarantee period?

A: 12 months. Our machine comes with 1 year warranty, except for wearing parts and damage incurred by improper usage/negligence. After this period , you can still enjoy our service all the time.

Q3. Does your company have any certification?

A: Yes. We have CE , ISO 9001 and so on.

Q4. Do you have machine operating instruction?

A: Yes. We have English machine operating instruction together with the machine.

Q5. What's the delivery time?

A: Generally, it takes 15-25 working days to finish an order. Exact delivery time would be confirmed by further communication.

Q6. Can i put my own LOGO on the products?

A: Yes. You can put your own LOGO on the products.