- Product Details

- {{item.text}}

Quick Details

-

Place of Origin:

-

Guangdong, China

-

Brand Name:

-

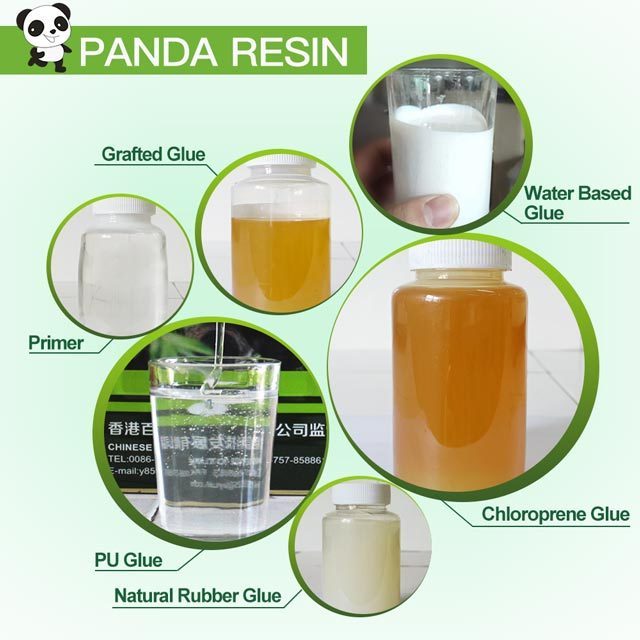

PANDA

-

Model Number:

-

31T-12kg

-

Type:

-

Primer

-

Appearance:

-

Liquid

-

Color:

-

Light yellow

-

MOQ:

-

10 barrel

-

Packing:

-

14 Liter /barrel

-

Application:

-

TPR TR shole

-

Pot life:

-

2hrs(After mixing hardener)

-

Delivery time:

-

10 Days

-

Shelf life:

-

6-12 Months

-

Characteristics:

-

Exellent effect

Quick Details

-

CAS No.:

-

N/A

-

Other Names:

-

cleaner

-

EINECS No.:

-

N/A

-

Place of Origin:

-

Guangdong, China

-

Brand Name:

-

PANDA

-

Model Number:

-

31T-12kg

-

Type:

-

Primer

-

Appearance:

-

Liquid

-

Color:

-

Light yellow

-

MOQ:

-

10 barrel

-

Packing:

-

14 Liter /barrel

-

Application:

-

TPR TR shole

-

Pot life:

-

2hrs(After mixing hardener)

-

Delivery time:

-

10 Days

-

Shelf life:

-

6-12 Months

-

Characteristics:

-

Exellent effect

We are the supplier of various kinds of shoe making chemicals, please do not hesitate to contact us, if you have any inquiry.

TPR Primer for treating tpr ,tr shoe sole with excellent effect 31T-12KG

| Product information | |

| Main Component | Synthetic rubber |

| Shelf Life | 6-12 months |

| Appearance | Light yellow liquid |

| PH | 6-8 |

| Packaging | 14 Liter /barrel or according to your advance request |

| Pot life |

2hrs (After mixing hardener) Add 3-5% hardener: Used within 2 hours for best bonding performance. |

| Other models | 01P 02P 04U 05U 03P 11L 21R 22R 23R/A 23R/B 25R/A 25R/B 31T 33T 51E 52E UV60 15L 18L 90N 91W |

Tpr glue primer for tpr material 31T

APPLICATIONS & CHARACTERISTICS

1. 32T is a toluene-free cement for TPR injection process.

2. Excellent yellowing resistance performance.

|

Applications |

TPR rubber Primer for shoes surface before bonding NOTICE

1. Keep away from flame, store in cool, dry, well-ventilated place.

2. Operator must wear PPE.

Tpr bonding primer for adhesive OPERATION METHOD

1.Shoe materials → pre-treatment → 32T+ 5%Hardener → Drying→ cement

2.Drying Condition: Traditional Oven : (55 ℃ ± 5 ℃) X 3’-5’

NIR : (55 ℃ ± 5 ℃) X 2’-4’

NIR+MIR oven condition:(50℃ ~ 65℃) X 90"~180"

PS:

Drying condition is suggested to set according to the operation of different materials, and special models.

Note: Recommended Hardener is RC.

1. NIR oven drying condition is suggested to set according to the operation of different models, and special models.

2. For special models with NIR oven, the operation needs to be adjusted according to factories’ condition

(e.g. oven,

Layout…).

When the drying condition is continuous two sections:

Recommended the first section Low-temperature drying (35-45℃x3’-4’) and the second section drying (50-60℃x3’-4’)

The thickness of the adhesive on the materials should be enough and even to make sure its adhesion effect.

3. Before factories adjust the drying condition based on the different types of NIR+MIR ovens, must make

sure the bonding

test is passed. For adhesive's film-forming ability, when adjust the drying condition, time-no less than 90",temperature- no

higher than 65℃.

4. For special shoe types or porous material such as mesh, factories can adjust the NIR+MIR oven time (if necessary, prolong

it)and temperature depending on actual inner trial test for bonding and drying with FTY

CEs. By no means should the

temperature be higher than 65℃.