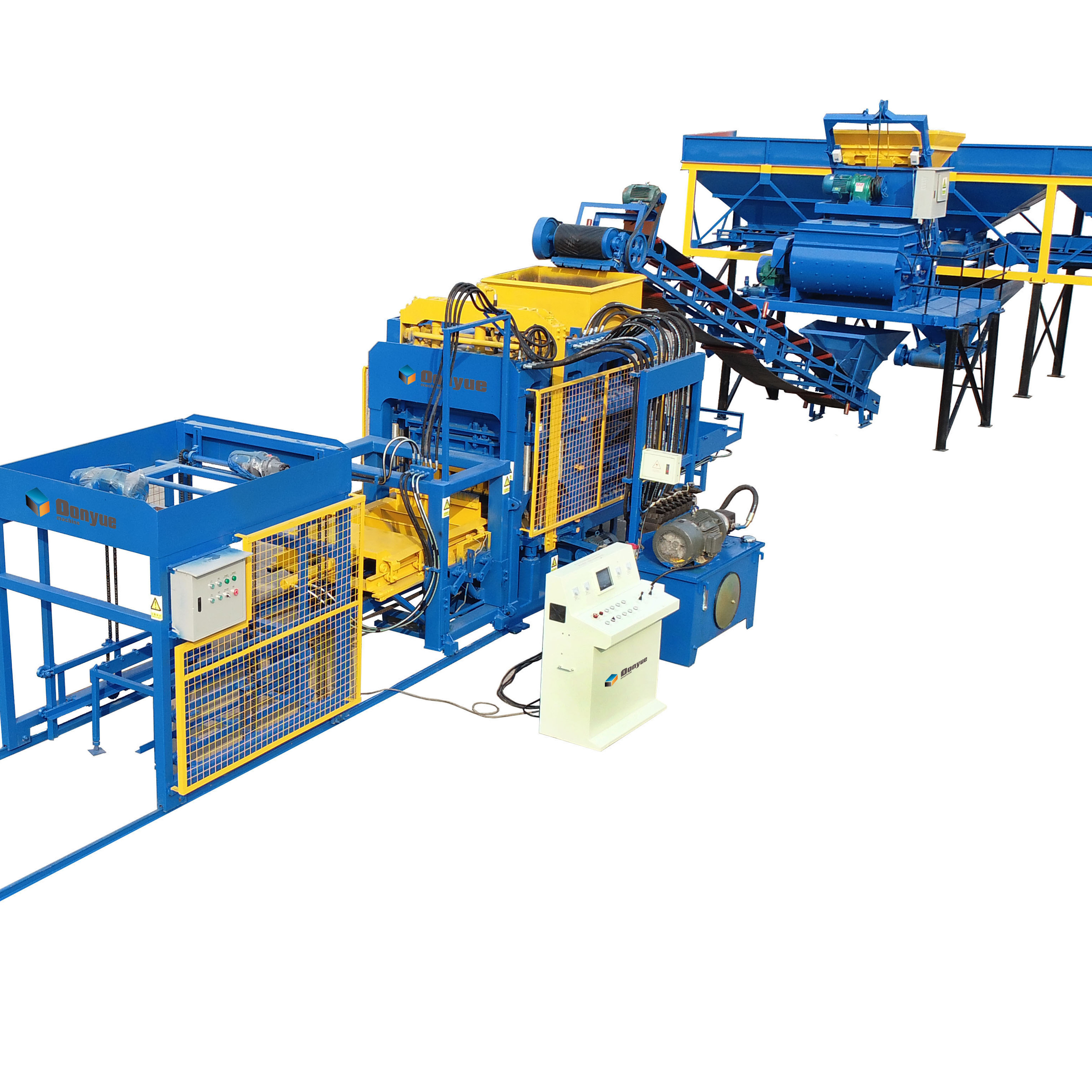

- Product Details

- {{item.text}}

Quick Details

-

Brick size:

-

400*100*200 mm, 400*150*200 mm, 400*200*200 mm

-

Place of Origin:

-

Shandong, China

-

Brand Name:

-

donyue

-

Voltage:

-

According to customer requirements

-

Dimension(L*W*H):

-

3200x2000x2750mm

-

Weight (KG):

-

10500 kg

-

Raw material:

-

cement

-

Block Type:

-

Paving Brick

-

Keywords:

-

Automatic Cement Block Moulding Machine

-

Model:

-

QT6-15

-

Mixer model:

-

JS500

-

Advantage:

-

Provide Technical Service

-

Pallet size:

-

1150X720X25mm

-

Weight:

-

10.5T

-

water consumption:

-

5-8Ton/day

-

Vibration force:

-

60-80 KN

Quick Details

-

Type:

-

Hollow Block Making Machine, Paving Block Making Machine, Interlock Block Making Machine

-

Brick Raw Material:

-

Cement

-

Production Capacity (Pieces/8 hours):

-

4480 pcs/8hours, 3400 pcs/8hours, 5760 pcs/8hours, 3000 pcs/8hours, 3200 pcs/8hours

-

Brick size:

-

400*100*200 mm, 400*150*200 mm, 400*200*200 mm

-

Place of Origin:

-

Shandong, China

-

Brand Name:

-

donyue

-

Voltage:

-

According to customer requirements

-

Dimension(L*W*H):

-

3200x2000x2750mm

-

Weight (KG):

-

10500 kg

-

Raw material:

-

cement

-

Block Type:

-

Paving Brick

-

Keywords:

-

Automatic Cement Block Moulding Machine

-

Model:

-

QT6-15

-

Mixer model:

-

JS500

-

Advantage:

-

Provide Technical Service

-

Pallet size:

-

1150X720X25mm

-

Weight:

-

10.5T

-

water consumption:

-

5-8Ton/day

-

Vibration force:

-

60-80 KN

Related Products

Product Description

SPECIFICATIONS

AS the molds are changeable, this concrete brick machine is able to produce different types of blocks/bricks, and this is a

hydraulic machine can produces a stronger block, due to the greater pound pressure applied by the hydraulic system.

The block manufacturer can also realize substantial savings by using less cement. A ratio from 8:1 to 11:1 sand/cement can be

achieved. This machine is designed for the manufacturer with a steady year turnover and with a certain number cash to make the

factory running.

hydraulic machine can produces a stronger block, due to the greater pound pressure applied by the hydraulic system.

The block manufacturer can also realize substantial savings by using less cement. A ratio from 8:1 to 11:1 sand/cement can be

achieved. This machine is designed for the manufacturer with a steady year turnover and with a certain number cash to make the

factory running.

|

Main Technical Parameter

|

|

|

|

|

||||

|

Host machine size

|

3200x2300x2750mm

|

|

Mixer model

|

JS500

|

||||

|

Vibration Force

|

60-80KN

|

|

Host Machine Power

|

45KW

|

||||

|

Host machine weight

|

8.5T

|

|

Pallet Size

|

1150x7200x25mm

|

||||

|

Production Capacity

|

|

|

|

|

||||

|

Name

|

Block size

|

pcs per mould

|

pcs per hour

|

pcs per 8 hour

|

||||

|

hollow block mould

|

400x200x200MM

|

6

|

1080-1440

|

8640-11520

|

||||

|

solid brick mould

|

240x115x53MM

|

40

|

8470-12000

|

67760-96000

|

||||

|

paver brick mould

|

200x100x60MM

|

27

|

4860

|

38880

|

||||

|

paver brick mould

|

200x163x60MM

|

18

|

3240

|

25020

|

||||

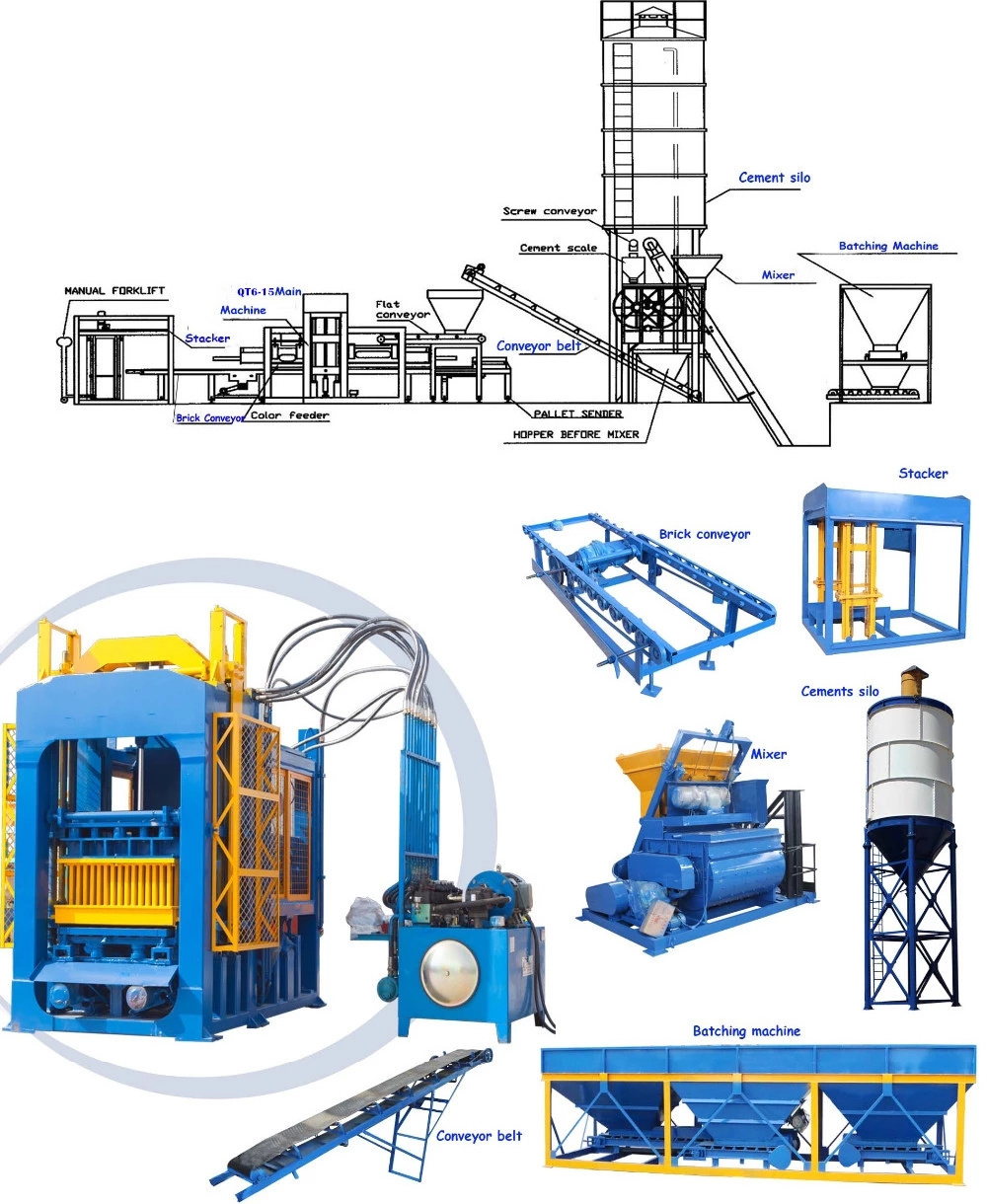

QT6-15 - Best selling automatic model

We provide complete technical support, including site planning, installation guidance, technical training and after-sales service.

1. Material and welding : All material and spare parts selected according to international CE standard, Carbon dioxide protection will assure whole line stable running.

2. Electric control system : We selected original Mitsubishi PLC combine with independent machine control system to assure stable and high-efficiency working status.

3. Switches and motor :Switched will use Japan Omron or France Schneider, motor will use Siemens or ABB band.

4. Hydraulic system : The machine adopting the advanced hydraulic molding technology, it can assure the block machine have stable and high-efficiency working status, and the blocks produced are of better quality,larger density and higher strength.

5. Block mould : Our block moulds are made of Q355R manganese steel.Besides the good raw material, precise line cutting technology and 900ºC carburizing heat treatment technology are all adopted in the process of brick moulds production.Then the mould size error can be controlled within 0.002mm . The surface layer of the brick moulds get higher hardness (achieving HRC54-58) and better wear resistance.

6. Vibration system: The machine adopts the special technology to optimize the vibration shaft, so that the proportion of

vibration is covered in the whole surface range, so the product quality is greatly improved and the noise is effectively reduced.

The machine's unique fixed platform design forms can improve the molding speed and dimensional accuracy.

We provide complete technical support, including site planning, installation guidance, technical training and after-sales service.

1. Material and welding : All material and spare parts selected according to international CE standard, Carbon dioxide protection will assure whole line stable running.

2. Electric control system : We selected original Mitsubishi PLC combine with independent machine control system to assure stable and high-efficiency working status.

3. Switches and motor :Switched will use Japan Omron or France Schneider, motor will use Siemens or ABB band.

4. Hydraulic system : The machine adopting the advanced hydraulic molding technology, it can assure the block machine have stable and high-efficiency working status, and the blocks produced are of better quality,larger density and higher strength.

5. Block mould : Our block moulds are made of Q355R manganese steel.Besides the good raw material, precise line cutting technology and 900ºC carburizing heat treatment technology are all adopted in the process of brick moulds production.Then the mould size error can be controlled within 0.002mm . The surface layer of the brick moulds get higher hardness (achieving HRC54-58) and better wear resistance.

6. Vibration system: The machine adopts the special technology to optimize the vibration shaft, so that the proportion of

vibration is covered in the whole surface range, so the product quality is greatly improved and the noise is effectively reduced.

The machine's unique fixed platform design forms can improve the molding speed and dimensional accuracy.

Details Images

production process

Materials

Two options for reference

1. 8%-10% cement, 30-40% sand, 50-60% crushed stone

2. 8-10% cement, 30% fly ash, 60% sand or stone powder

Other materials can also be used

Other materials can also be used

Finished products

Block samples

The machine can produce various hollow bricks, solid bricks and pavers by changing the moulds. The following bricks are somecommon brick types. At the same time, we can customize the brick moulds for you according to your specific requirements.

Our customers

Factory style

Hot Searches