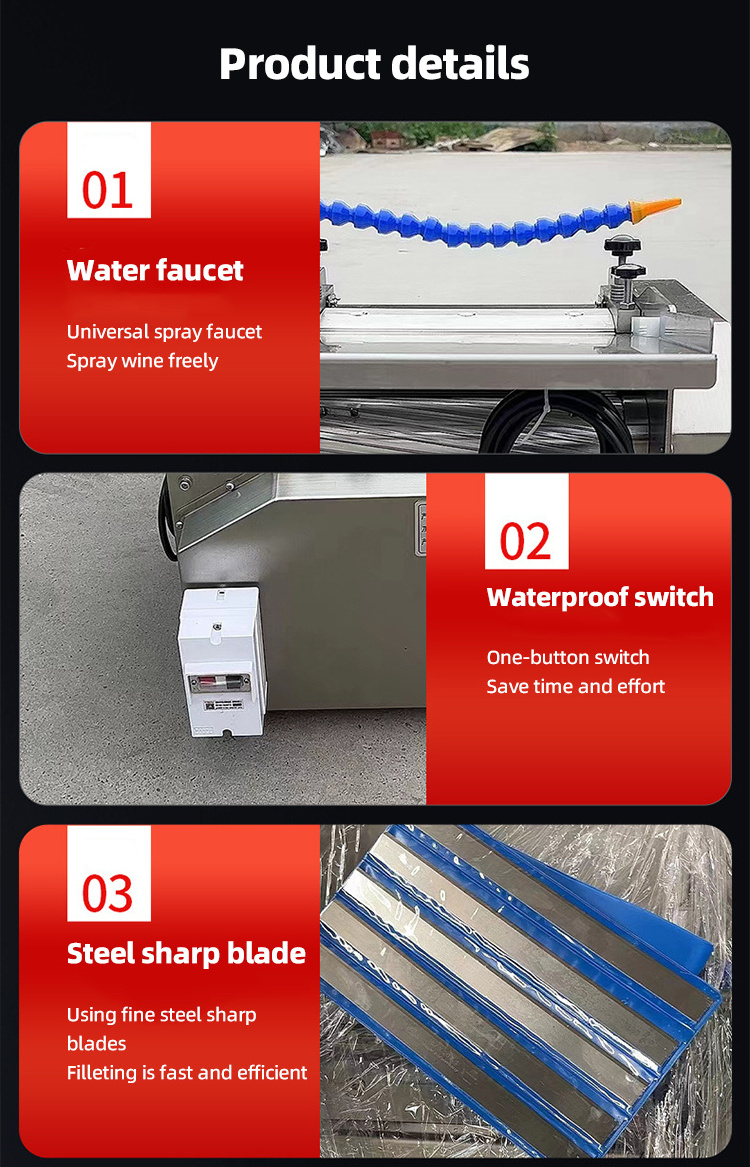

- Product Details

- {{item.text}}

Quick Details

-

Brand Name:

-

YuQing

-

Voltage:

-

110V/220V/380V

-

Power:

-

750w+120w

-

Dimension(L*W*H):

-

1520*930*1140mm

-

Weight:

-

180 KG

-

Product name:

-

Professional Fish Peeling Machine

-

Application:

-

commercial Restaurant fish skin removing

-

Usage:

-

fish Food Skinner Cleaning

-

Material:

-

Stainless Steel

-

Feature:

-

goog quality Large Capacity

Quick Details

-

Marketing Type:

-

Hot Product 2023

-

Production Capacity:

-

60-90pc/min

-

Place of Origin:

-

Henan, China

-

Brand Name:

-

YuQing

-

Voltage:

-

110V/220V/380V

-

Power:

-

750w+120w

-

Dimension(L*W*H):

-

1520*930*1140mm

-

Weight:

-

180 KG

-

Product name:

-

Professional Fish Peeling Machine

-

Application:

-

commercial Restaurant fish skin removing

-

Usage:

-

fish Food Skinner Cleaning

-

Material:

-

Stainless Steel

-

Feature:

-

goog quality Large Capacity

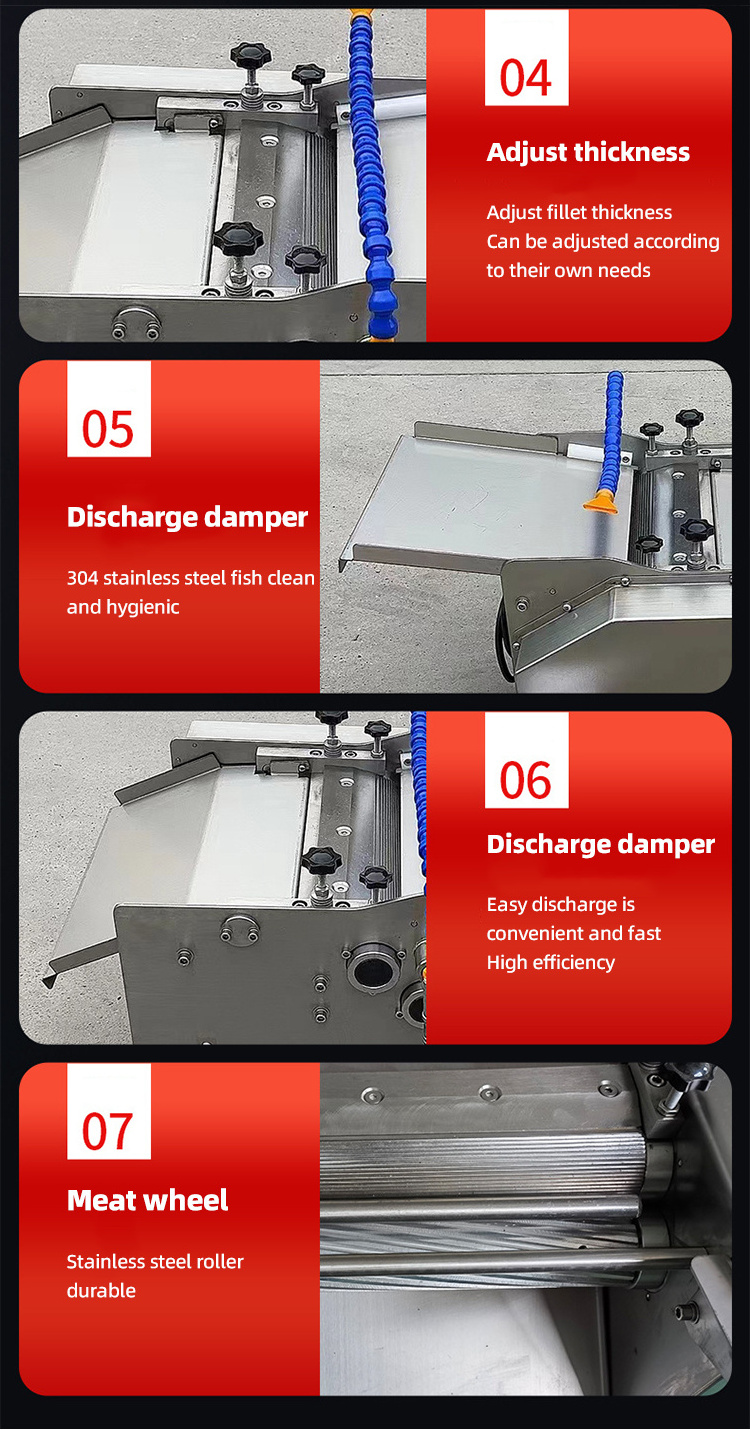

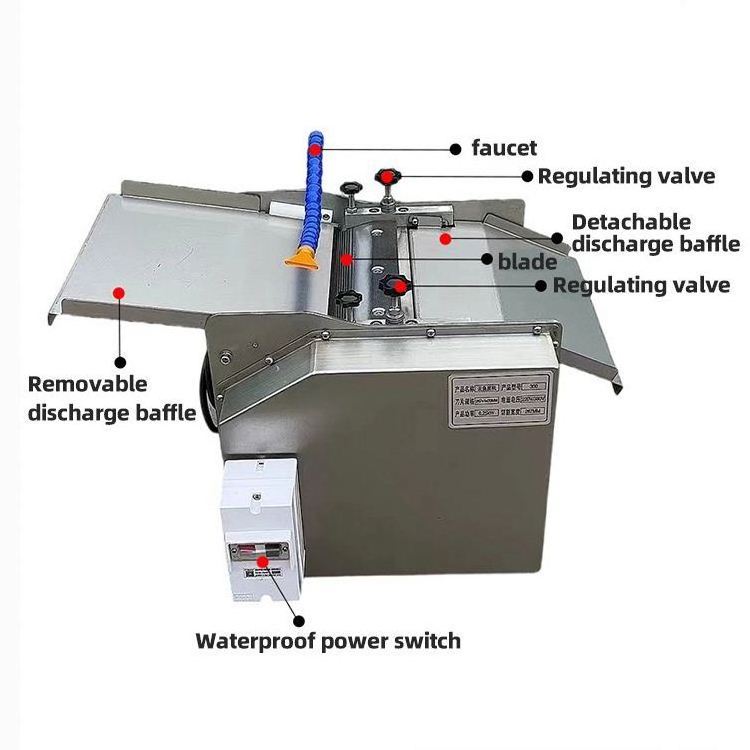

The fish skinning machine places the fish fillets with open edges (skin down) at the feed inlet, and the machine automatically peels the skin. It has large output and high production efficiency. The skinning yield is as high as 99% and the loss is small. The automatic peeling machine with conveyor belt is equipped with a feeding conveyor belt adjustment device and a loading hopper adjustment device. The operation mode can be switched at will. It uses imported high-quality 304 stainless steel, Korean knives and electronic components. It has a professional waterproof design and is easy to clean. It is suitable for fish peeling operations in various aquatic product processing plants, fishery companies, food processing plants, large catering and other units. It has large output, high efficiency and good peeling effect.

The automatic fish skinning machine can directly place the fish fillets on the feeding conveyor belt, and the conveyor belt enters the knife edge of the knife holder for self-peeling effect, which can avoid and reduce the work-related injuries caused by manual direct alignment of the knife edge, and the finale simulates human hands to pull the fish. fillets, thus improving the yield rate of fish fillets and meat.

The fish skinning machine places the fish fillets with open edges (skin down) at the feed inlet, and the machine automatically peels the skin. It has large output and high production efficiency. The skinning yield is as high as 99% and the loss is small. The automatic peeling machine with conveyor belt is equipped with a feeding conveyor belt adjustment device and a loading hopper adjustment device. The operation mode can be switched at will. It uses imported high-quality 304 stainless steel, Korean knives and electronic components. It has a professional waterproof design and is easy to clean. It is suitable for fish peeling operations in various aquatic product processing plants, fishery companies, food processing plants, large catering and other units. It has large output, high efficiency and good peeling effect.

The automatic fish skinning machine can directly place the fish fillets on the feeding conveyor belt, and the conveyor belt enters the knife edge of the knife holder for self-peeling effect, which can avoid and reduce the work-related injuries caused by manual direct alignment of the knife edge, and the finale simulates human hands to pull the fish. fillets, thus improving the yield rate of fish fillets and meat.

Features

1. Wide range of uses: It can extract the skins of a variety of fish, including squid, tilapia, catfish, cod, plaice, mullet, snapper and other fish.

2. High efficiency: One machine can meet the operating capacity of 30-50 people, and the equipment cost can be recovered in the short term.

3. Good effect: good peeling effect, clean and neat peeling.

4. High yield: higher yield than manual peeling.

5. Easy to clean: The equipment is all made of stainless steel, with humanized design and easy to disassemble and clean.

|

Model |

FPM-07270 |

FPM-07400 |

|

Capacity |

15-30pc/min |

60-90 pc/min |

|

Rotating speed |

14m/min |

44m/min |

|

Blade length |

270mm |

400mm |

|

Power |

0.2KW |

0.75kw+0.12kw |

|

Weight |

48KG |

180KG |

|

Size |

540*420*410mm |

1520×930×1140mm |

|

Voltage |

380/220/110V |

380/220/110V |