- Product Details

- {{item.text}}

Quick Details

-

Voltage:

-

380V/415V/440V

-

Power:

-

Customized

-

Dimension(L*W*H):

-

Customized

-

Weight (KG):

-

300

-

Certification:

-

BV/TUV/ISO

Quick Details

-

Place of Origin:

-

Shandong, China

-

Machine Type:

-

Sand molding machine

-

Brand Name:

-

Antai

-

Voltage:

-

380V/415V/440V

-

Power:

-

Customized

-

Dimension(L*W*H):

-

Customized

-

Weight (KG):

-

300

-

Certification:

-

BV/TUV/ISO

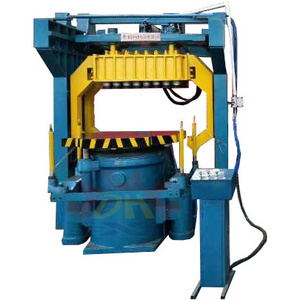

Foundry green sand jolt squeeze molding machine

Brief introduction

Jolt Squeeze Molding Machine is suitable for mass production of single molding plate or single molding box of medium and small sized castings, which can produce cope or drag. The machine adopts micro vibration compaction mechanism, large shock force and compaction strength. So it can meet simple or complex molding requirements withour pre-shock. It is one of the indispensable tools for mechanized molding and has gradually replaced traditional manual moldling.

This machine consisits of machine body, pattern stripping mechanism, jolting compaction mechanism, rocker arm pressure head part and pneumatic piping system.

Application range

Z143W, Z144W and Z145W models are the ideal choice for production of small castings lighting accessories, machine parts, furniture hardware and heating equipment. Z146W, Z147W and Z147Q models are usually for castings of various mechanical parts such as textile parts, plumbing fittings, valve parts and sewing machine casings. Z148W and Z149Q are suitable for foundry workshops such as auto parts, tractor parts, mining, machine tools, light industrial textile machinery industry.

We can also accept customzed requipment based on customers' exact requirements.

Advantages

1. Pneumatic components, long service life and convenient operatoin, effectively improves production efficiency.

2. Optimized structure design. The square box frame structure greatly improves the rigidity of machine body.

3. Micro vibration compaction process can greatly improve compaction strength and surface roughness to stabilize product quality. The hardness of sand molding can reach above HB90.

4. The shock part is equipped with a buffer spring to effectively reduce the impact of the machine on the foundation.

5. The pattern stripping mechanism adopts the cylinder, the crank, the connecting rod and the synchronous shaft to realize the synchronous lifting.

6. Fully adopt pneumatic parts to achieve overall function of the controll part, easy operation and convenient maintenance.

Technical Specifications

| Item | Z143W | Z144W | Z145W | Z146W | Z147W | Z147Q | Z148W | Z149Q |

|

Max size of

|

500×400×100 | 500×400×180 | 500×450×200 | 600×500×200 | 650×550×250 | 750×650×300 | 800×600×300 | 1000×800×320 |

|

Worktable size (mm) |

560×420 | 560×465 | 620×520 | 700×550 | 750×600 | 850×700 | 900×730 | 1100×850 |

|

Compressed air (Mpa) |

0.5 | 0.6 | 0.6 | 0.6 | 0.6 | 0.6 | 0.6 | 0.6 |

|

Compression force(kgf) |

4000 | 4200 | 6300 | 7000 | 8000 | 9500 | 10000 | 15000 |

|

Jolt load(kgf) |

250 | 280 | 300 | 300 |

400

|

500 | 600 |

800

|

|

Compaction stroke(mm) |

100 | 120 | 120 | 160 | 200 | 200 | 200 | 250 |

|

Molding stroke (mm) |

160 | 160 | 160 | 200 | 220 | 250 | 350 | 350 |

|

Distance from

pressure head to worktable (mm) |

200~370 | 300~400 | 300~450 | 350~450 | 450~600 | 550~650 | 600~700 | 700~800 |

|

Distance from jolt platfrom to ground(mm) |

520

|

620 | 780 |

800

|

800

|

850 | 860 | 900 |

|

Productivity (mold/hour) |

40~60 | 40~60 | 40~60 | 40~60 | 40~60 | 40~60 | 40~60 | 40~60 |

|

Overall size (L*W*H)(mm) |

950×680×1330 | 1000×800×1420 | 1200×1000×1700 | 1400×1000×1700 | 1200×1100×1800 | 1250×1100×1900 | 1800×1300×2300 | 1060×1660×2300 |

Jolt Squeeze Moulding Machine Shipment

Manhole Cover Jolt Squeeze Moulding Machine

Brake Drum&Wheel Hub Jolt Squeeze Moulding Machine