- Product Details

- {{item.text}}

Quick Details

-

Brand Name:

-

E.P

-

Voltage:

-

380v/400v/415v

-

Dimension(L*W*H):

-

1.4*0.8*1.45(m)

-

Motor Power (Kw):

-

30kw

-

Power (kW):

-

30kw

-

Applicable Industries:

-

Wood Pellet Machine

-

Weight (KG):

-

770 KG

-

Model:

-

HSKL-R400

-

Type:

-

Flat Die Biomass Pellet Mill

-

Application:

-

Make Biomass Pellets

-

Raw material:

-

Sawdust\straw\rice Husk\wood Waste

-

After-sales Service Provided:

-

Online support

-

After Warranty Service:

-

Field maintenance and repair service

-

Local Service Location:

-

None

-

Showroom Location:

-

None

-

Certification:

-

CE ISO

-

Color:

-

Customizable

Quick Details

-

Pellet Diameter (mm):

-

2.5 - 8

-

Output (kg/h):

-

350 - 450 kg/h

-

Place of Origin:

-

Henan, China

-

Brand Name:

-

E.P

-

Voltage:

-

380v/400v/415v

-

Dimension(L*W*H):

-

1.4*0.8*1.45(m)

-

Motor Power (Kw):

-

30kw

-

Power (kW):

-

30kw

-

Applicable Industries:

-

Wood Pellet Machine

-

Weight (KG):

-

770 KG

-

Model:

-

HSKL-R400

-

Type:

-

Flat Die Biomass Pellet Mill

-

Application:

-

Make Biomass Pellets

-

Raw material:

-

Sawdust\straw\rice Husk\wood Waste

-

After-sales Service Provided:

-

Online support

-

After Warranty Service:

-

Field maintenance and repair service

-

Local Service Location:

-

None

-

Showroom Location:

-

None

-

Certification:

-

CE ISO

-

Color:

-

Customizable

Product Description

Roller-driven pellet mills are specially designed equipment for pelletizing powdery biomass materials, including wood dust, crop stalk, bamboo dust, rice husk, peanut shells, bagasse, alfalfa and so on. E.P flat-die roller-driven pellet mills are efficient equipment. You can adjust the compression ratio of the pellet making machine to fit different materials.

|

Model

|

Power

|

Capacity

(for feed pellets)

|

Capacity

(for wood pellets)

|

Size

|

|

HSKL-R200

|

7.5kw

|

180-290kg/h

|

80-120kg/h

|

1.46*0.95*1.1(m)

|

|

HSKL-R300

|

22kw

|

570-850kg/h

|

250-350kg/h

|

1.35*0.75*1.4(m)

|

|

HSKL-R400

|

30kw

|

800-1100kg/h

|

350-450kg/h

|

1.4*0.8*1.45(m)

|

Structure & Principle

Components

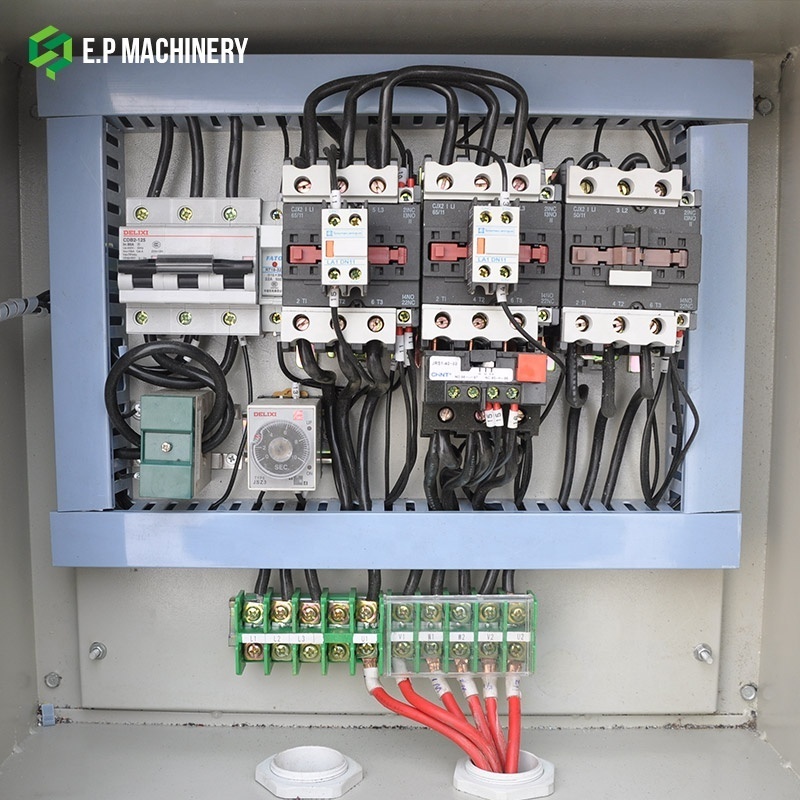

Electric control cabinet :

The safety electric control system in the cabinet is totally approved by CE standard; Emergency stop button can be used for emergency operation;

Gear box : It is made of superior steel. It won’t make much noise when it works. It has good shock absorption function. Compared with traditional belt-driving device, it is more efficient;

Mould and rollers : those are made of high-quality alloy steel, whose hardness is up to 55-60HRC.

Gear box : It is made of superior steel. It won’t make much noise when it works. It has good shock absorption function. Compared with traditional belt-driving device, it is more efficient;

Mould and rollers : those are made of high-quality alloy steel, whose hardness is up to 55-60HRC.

Working principle

Firstly, the powdery biomass material is fed into the feeding port of the pellet mill and falls on the mould. Then, the motor

drives the main shaft to rotate and the rotating shaft will drive the rollers to rotate. In the rotating process of the rollers,

powdery material will be squeezed in to the cylinder holes in mould. After some time, the pressed material will come out from the holes in the mould. At this time, the rotating cutter under the mould will cut off the pressed material and finished pellets appear.

drives the main shaft to rotate and the rotating shaft will drive the rollers to rotate. In the rotating process of the rollers,

powdery material will be squeezed in to the cylinder holes in mould. After some time, the pressed material will come out from the holes in the mould. At this time, the rotating cutter under the mould will cut off the pressed material and finished pellets appear.

Features & Advantages

Advantages

1. The mould is reversible. Besides, the rollers are made of high-hardness 55-60 RC alloy steel;

2. Different moulds matches with different compression ratio. A pellet mill can be equipped with several different moulds;

3. The pelleting rate and output of E.P pellet making machines are both high;

4. The pellet mill adopts gear driving. The gears are made of high quality alloy steel which is quenched;

5. Stable running, low noise, large capacity, long service life;

6. With safe and CE-approved electrical control system;

7. There is an emergency stop button on the pellet making mill. Once emergent accidents happened, you could press the button to stop the machine.

Certifications

Why choose us

Our Advantages

1. We have a wealth of project experience and can provide complete technical guidance.

2. Provide integrated installation and complete guidance services

Strong Technical Team

Customized service:

customize equipment according to your requirements.

Installation service: send our workers to your country to install the production line.

Installation service: send our workers to your country to install the production line.

Packaging & Shipping

Packaging Specification:

Outside Package : Wooden Packing as Exported Standard.

Inner Package : Stretch Film

About Shipping

We can be responsible for the shipping according to the customers's requirments to ship the machines by sea, express or air. Besides, we can cooperate with your agent if you have shipping forwarder in China.

Hot Searches