- Product Details

- {{item.text}}

Quick Details

-

Filling Accuracy:

-

±1mm

-

Voltage:

-

220V/110V

-

Place of Origin:

-

Jiangsu, China

-

Brand Name:

-

Fill Pack

-

Dimension(L*W*H):

-

800*300*500mm

-

Weight:

-

40 KG

-

After-sales Service Provided:

-

Engineers available to service machinery overseas

-

Key words:

-

pneumatic beverage filling machine

-

Material:

-

High quality stainless steel

-

Filling material:

-

Various material

-

Filling range:

-

25-250ml / 50-500ml / 100-1000ml / 200-2000ml

-

Air power:

-

0.6MPa

-

Working pressure:

-

0.1-0.5MPa

-

Filling precision:

-

±1%

-

Filling speed:

-

10-30 bottles/min

-

Air consumption:

-

0.015-0.025m3/min

Quick Details

-

Machinery Capacity:

-

1800BPH

-

Packaging Material:

-

Glass, Metal, Plastic

-

Filling Material:

-

Other, Milk, Water, Oil, Juice

-

Filling Accuracy:

-

±1mm

-

Voltage:

-

220V/110V

-

Place of Origin:

-

Jiangsu, China

-

Brand Name:

-

Fill Pack

-

Dimension(L*W*H):

-

800*300*500mm

-

Weight:

-

40 KG

-

After-sales Service Provided:

-

Engineers available to service machinery overseas

-

Key words:

-

pneumatic beverage filling machine

-

Material:

-

High quality stainless steel

-

Filling material:

-

Various material

-

Filling range:

-

25-250ml / 50-500ml / 100-1000ml / 200-2000ml

-

Air power:

-

0.6MPa

-

Working pressure:

-

0.1-0.5MPa

-

Filling precision:

-

±1%

-

Filling speed:

-

10-30 bottles/min

-

Air consumption:

-

0.015-0.025m3/min

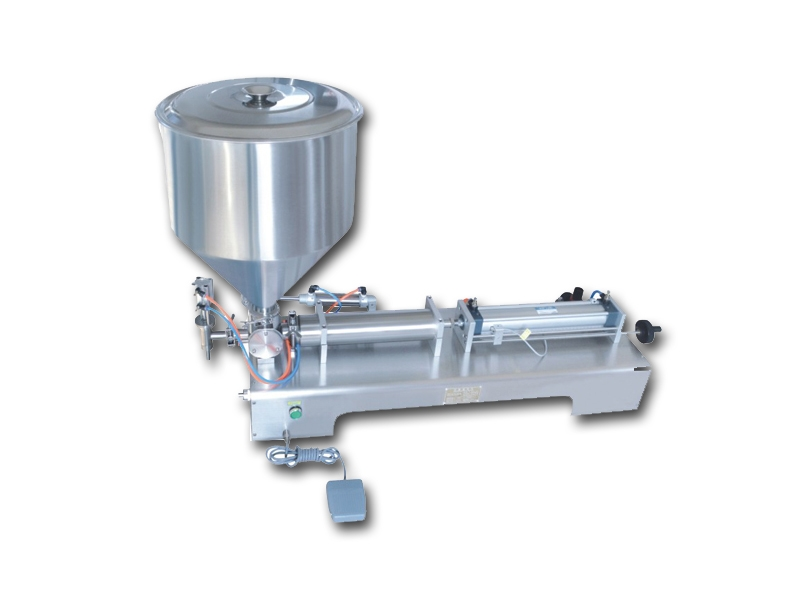

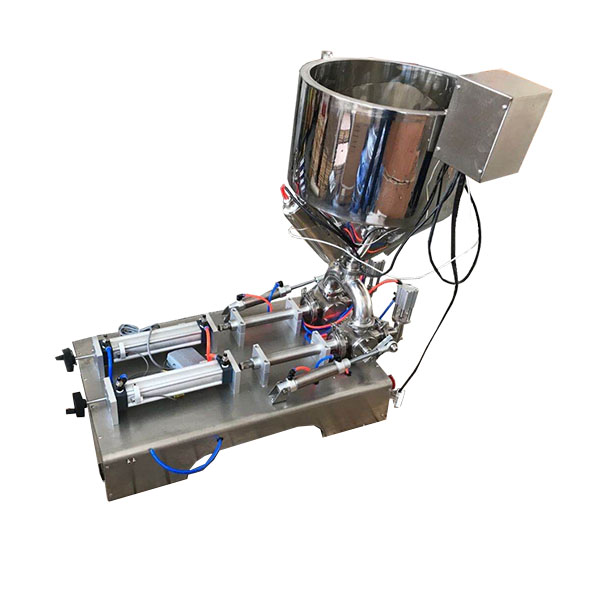

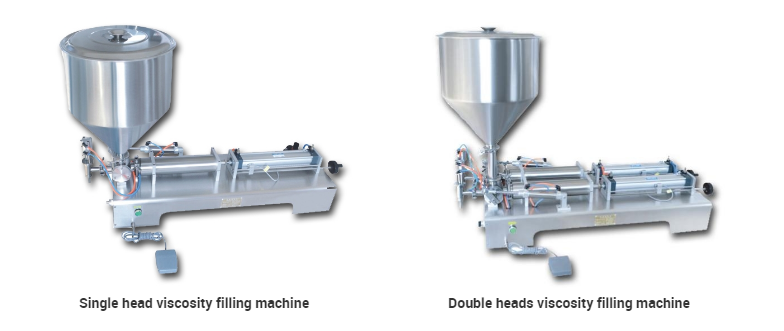

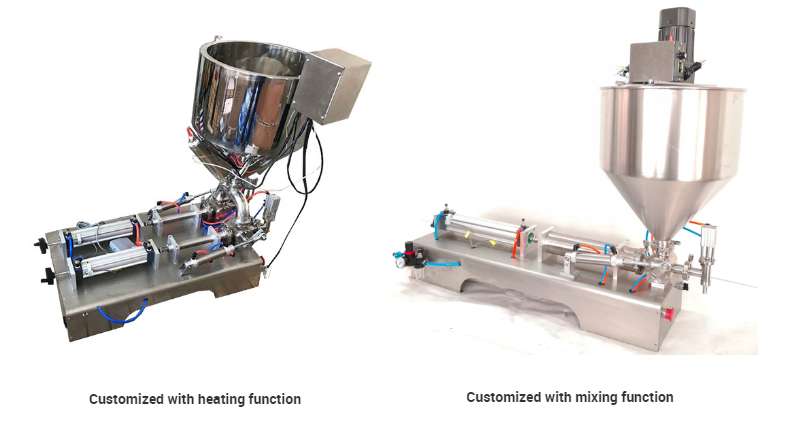

semi-auto pneumatic filling machine / equipment / line for water / liquid / condense canned / meat / sauce / milk

Parameters Table of pneumatic filling equipment, details as follows :

Usage:

The pneumatic filling line is used to filling food industry such as jam, meat sauce,It can be used to filling for all kinds of paste.

Principle:

The pneumatic filling machine adopts pneumatic working principle, simple operation, high filling precision, is a certain concentration or certain size granular materials ideal filling equipment.

The machine is equipped with foot switch, it can stop working at any time.

Remark:

The pneumatic filling machine has round and square hopper, can be customized as customer’s requirements.

|

Type

|

QDG-250

|

QDG-500

|

QDG-1000

|

QDG-2000

|

|

Filling volume

( ml )

|

25 - 250

|

50 - 500

|

100 - 1000

|

200 - 2000

|

|

Filling accuracy

( FS )

|

+/- 1%

|

+/- 1%

|

+/- 1%

|

+/- 1%

|

|

Filling speed

( bottles/min)

|

10-30

|

10-30

|

10-30

|

10-30

|

|

Air consumption

( m3 / min )

|

0.015-0.025

|

0.015-0.025

|

0.015-0.025

|

0.015-0.025

|

|

Application pressure

( Mpa )

|

0.1-0.5

|

0.1-0.5

|

0.1-0.5

|

0.1-0.5

|

|

Exterior size

( mm )

|

800*300*500

|

800*300*500

|

800*300*500

|

800*300*500

|

|

Net weight

( kg )

|

40

|

40

|

40

|

40

|

QDG-2 model one head semi-auto manual pneumatic filling machine for liquid canned meat sauce milk

1. this

pneumatic liquid filling

machine is made of High quality stainless steel , therefore, it is rustless and corrosion resistant.

2. filling volume regulation hand wheel could adjust filling speed , improve the work efficiency.

3. charging hopper makes charging convenience.

The features of pneumatic condense filling equipment , details as follows:

1.The pneumatic filling machine has simple and reasonable structure, high filling precision, it is easy to operate.

2.It is the ideal equipment to filling liquid,for example, beverage、chemical and medical.

3.The pneumatic parts adopt famous brand pneumatic elements.

4.The material of the machine which contact the condenseare all made of stainless steel. It meets the GMP standard.

5.It equipped with the regulating handle, which can adjust the filling speed freely, the filling precision is high.

6.The pneumatic filling machine drip-proof, avoid drawing, and equipped filling lifting device.

1. the machine is packed by wooden case.

2. The delivery date is within 30 days after payment.

500 / 1000 / 1500 / 2000 LPH Pure mineral Drinking water RO Reverse Osmosis purifying treatment machine / system

water purification system

2000BPH A-Z Soft / carbonated drink / cola / sparkling water mixing processing bottling filling labeling packing line

Customer's service:

1. FILL-PACK

company

can provide turn-key project for you, only you have any idea to start beverage factory plant.

2. FILL-PACK company have pro

fessio

nal design team, our engineer can draw bottle samples and flow chart ofworkshop for you .

3. FILL-PACK company give you the best quotation for all kinds of beverage production, only you can tell me whichkind of drink you want to product, what is your capacit

y(how many bottles one ho

ur) what is you bottle material, pet or glass,etc

After service:

1. We send the engineers to help installing, commissioning and training, the engineers start from our factory area.

2. We supply below necessary documents with the machine:

a. Machine layout

b. Electricity diagram

c. Machine certificate

d. General manual book/maintenance book

3. After one year guarantee, the seller provides payable spare parts and technician's VISITING maintenance service.