- Product Details

- {{item.text}}

Quick Details

-

Model Number:

-

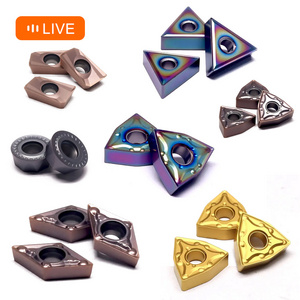

Carbide Cutting Tips

-

Particle:

-

Fine Grain

-

Type:

-

Power Tool Part

-

Material:

-

100% Virgin Raw Material

-

Grade:

-

K10, K20, K30, P10, P20, P30, P40, M10, M20 etc

-

Application:

-

Metal Working

-

Certificate:

-

ISO9001:2008

-

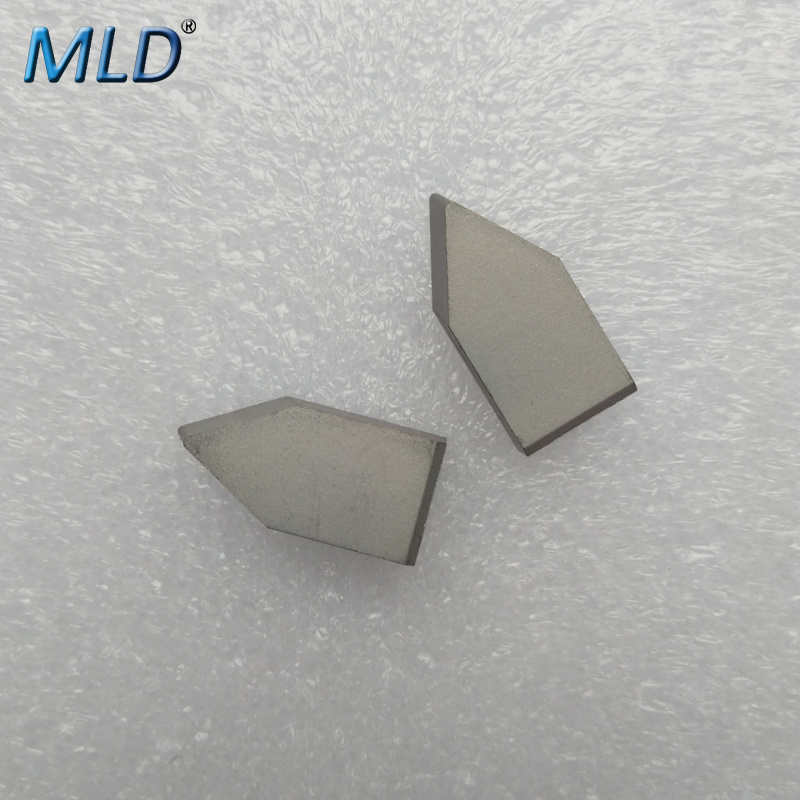

Surface:

-

Ground and Polished

-

Advantage:

-

High Wear Resistant

-

Service:

-

ODM OEM

-

Feature:

-

High Performance Cutting

Quick Details

-

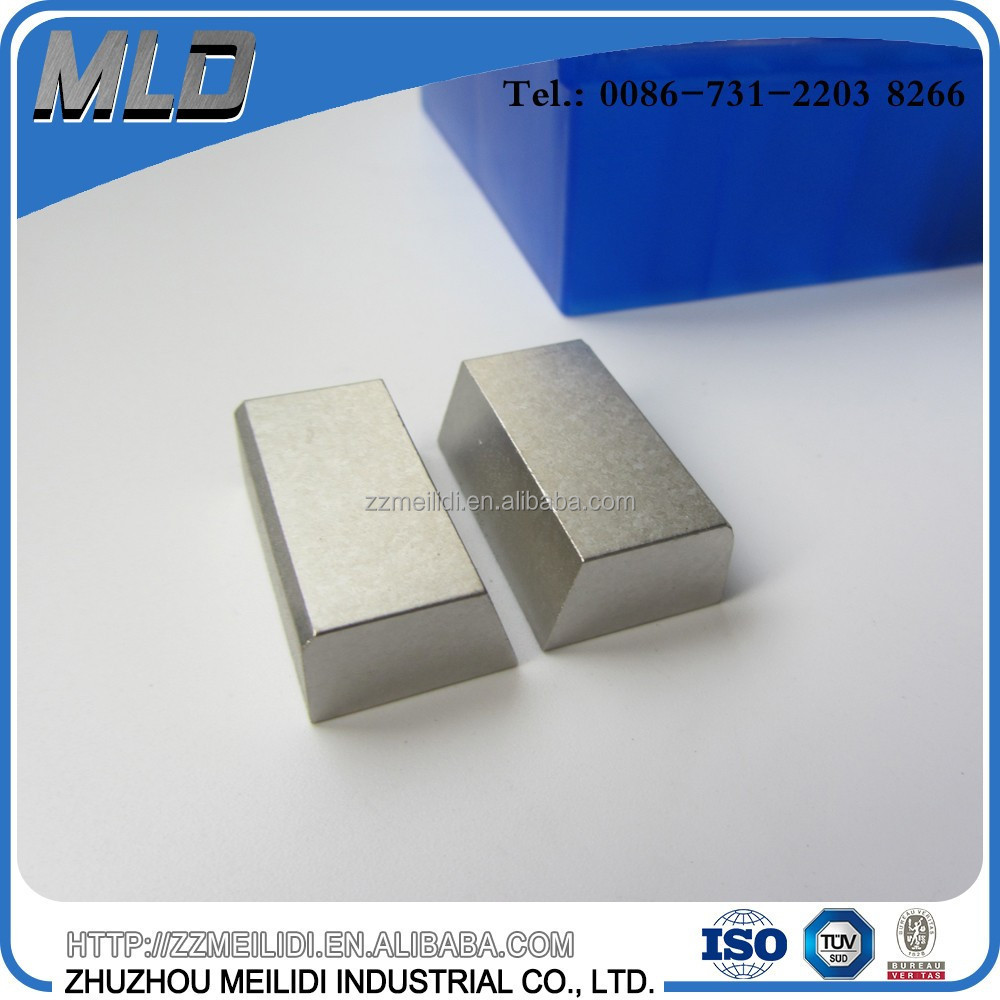

Alloy Specification:

-

Carbide Grade

-

Place of Origin:

-

Zhuzhou China, Zhuzhou China

-

Brand Name:

-

MLD

-

Model Number:

-

Carbide Cutting Tips

-

Particle:

-

Fine Grain

-

Type:

-

Power Tool Part

-

Material:

-

100% Virgin Raw Material

-

Grade:

-

K10, K20, K30, P10, P20, P30, P40, M10, M20 etc

-

Application:

-

Metal Working

-

Certificate:

-

ISO9001:2008

-

Surface:

-

Ground and Polished

-

Advantage:

-

High Wear Resistant

-

Service:

-

ODM OEM

-

Feature:

-

High Performance Cutting

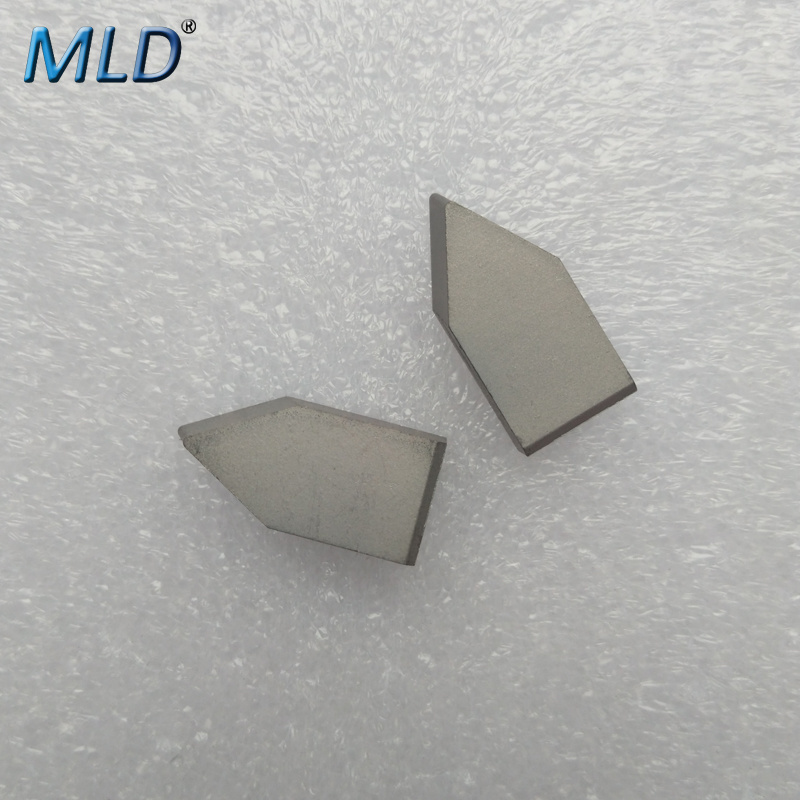

H10 P30 Tungsten Carbide Brazed Cutting Tips Lathe Cutting Tool Parts

Product Overviews

Product D e scription and Parameters

|

Geoglogical & Mining Use Cemented Carbide Ball Tooth/Tungsten Buttons Insert |

It's a kind of geoglogical and mining tools.Have different type: Drill bits, Ball teeth,Brazing Tips, Button ect. Some for embedding rotary drill bits for drilling coal and soft rock formation; some for embedding bits for core drilling of hard rock formations . |

|

Type |

P type flat roof, Z coin ball, X wedge. |

|

Application |

Carbide ball tooth has its unique performance,

therefore they are widely used in oil drilling and shovel snow, snow plough machine equipment, etc.

|

|

Features |

Carbide ball tooth has superior wear resistance and impact toughness, and similar products with higher speed of drilling and digging. Series of ball tooth bit passivation using cycle is long, not to grind the life span of about the same diameter grinding head drill bit 5-6 times of life, is beneficial to save auxiliary working hours, physical labor and reduce workers to speed up the project |

|

Density |

about 14.0-15.1g/cm3 |

|

Advantage |

Carbide ball tooth due to its high hardness of the cemented carbide and other characteristics are widely used in mining and quarrying and cutting process , also may be placed on a heavy excavators used in bit |

|

Field |

Carbide ball tooth is widely used in oil drilling and snow removal of snow plough device.In addition, carbide ball tooth in the cutting tool and coal mining machinery, road maintenance and drill tool also has a good application. Mining with cemented carbide balls tooth mainly used for quarrying, mining, and mining tools in tunnel and civil construction. |

|

Type |

Mining tool. |

|

Grade |

Density (g/cm3) |

Hardne s s (HRA) |

TRS (N/mm2) |

Recommended Application |

|

YG6 |

14.95 |

89.5 |

2580 |

Universal grade ,widely used in machining tools for cast ion,nonferrous metals and their alloys and nonmetal materials,wear parts ,and tools foe machining other alloys.

|

|

YG8 |

14.74 |

89.0 |

2710 |

|

|

YG6X |

14.93 |

91.0 |

2480 |

Suitable for the semi-of hard cast iron,nonferrous metals and their alloys, and also suitable for the semi-finishing and of common cast iron and high manganese steel work-pieces and for othe tools

|

|

YG6A |

14.89 |

91.5 |

2350 |

|

|

YG8C |

14.69 |

87.5 |

2850 |

Mainly used for rock drilling,auger tips and well drilling tools and at the same time for drilling stone walls,cemented construction and installation work,and machining stone materials. |

|

YG11C |

14.32 |

86.5 |

2940 |

|

|

YL10.2 |

14.45 |

91.5 |

2880 |

Mainly used for manufacturing strips and disc cutters and also for other tools . |

|

YM80 |

14.76 |

90.5 |

2590 |

For manufacturing strips and also for other tools |

|

YS2T |

14.45 |

91.5 |

2380 |

Used for disc cutters and also for other tool . |

|

YM15.1 |

14.05 |

92.5 |

2170 |

Suitable for the rough and of stainless steel, finishing of high strength steel sinishing and semi-sinishing of hardened steel ,and the machining of oron based heat resistant alloys and glass articles. |

Customized Solution