- Product Details

- {{item.text}}

Quick Details

-

Place of Origin:

-

Fujian, China

-

Brand Name:

-

SGW

-

Dimensions(L*W*H):

-

3300*860*1650mm, 3300*860*1650mm

-

Weight:

-

280 KG, 280KG

-

Certification:

-

CE

-

Max. Print Area:

-

350*600mm

-

Maximum printing speed:

-

15m/min

-

Maximum printing area:

-

250x350mm

-

Power:

-

220v

-

Printing color:

-

Single color

-

Table size:

-

300x500mm

-

Thickness range of printed matter:

-

0.2-100mm

-

Requirement of site:

-

4000x1000mm

Quick Details

-

Condition:

-

New

-

Color & Page:

-

Multicolor

-

Voltage:

-

220v/110v

-

Place of Origin:

-

Fujian, China

-

Brand Name:

-

SGW

-

Dimensions(L*W*H):

-

3300*860*1650mm, 3300*860*1650mm

-

Weight:

-

280 KG, 280KG

-

Certification:

-

CE

-

Max. Print Area:

-

350*600mm

-

Maximum printing speed:

-

15m/min

-

Maximum printing area:

-

250x350mm

-

Power:

-

220v

-

Printing color:

-

Single color

-

Table size:

-

300x500mm

-

Thickness range of printed matter:

-

0.2-100mm

-

Requirement of site:

-

4000x1000mm

Product Application

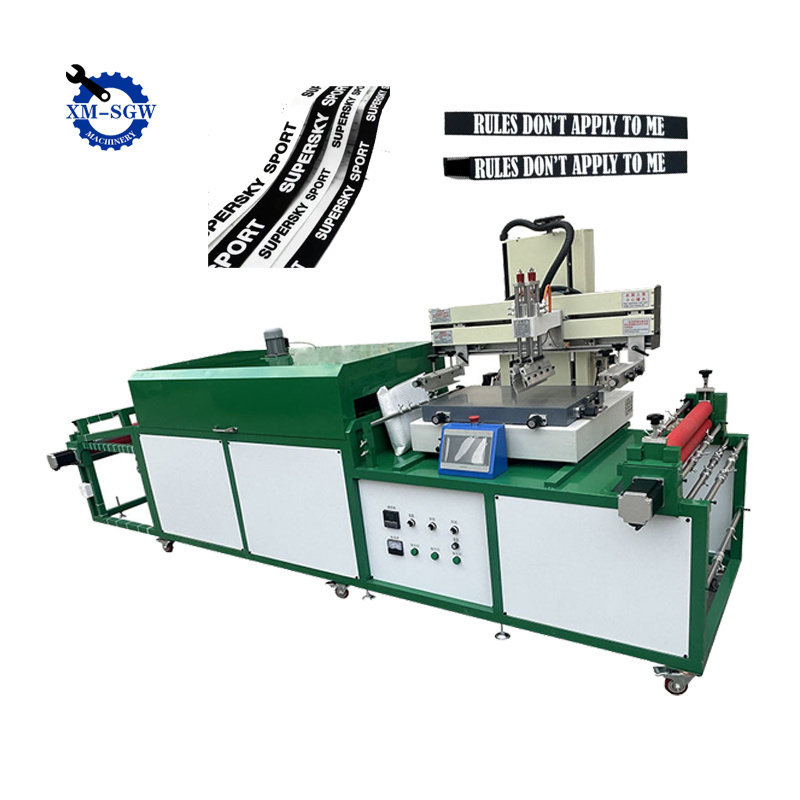

Top quality satin silk screen ribbon printing machine screen print machine with 250*350mm

Features of a roll to roll fully automatic non-woven fabric screen printing machine

It is usually used to print webbing/ribbon or a whole roll of tape of different materials. It is widely used, the printing range is adjustable, the operation is simple, and the molding is fast, which greatly saves labor costs. The machine is used for a long time, runs stably, and is not prone to errors.

Product Paramenters

Products Description

Machine Features

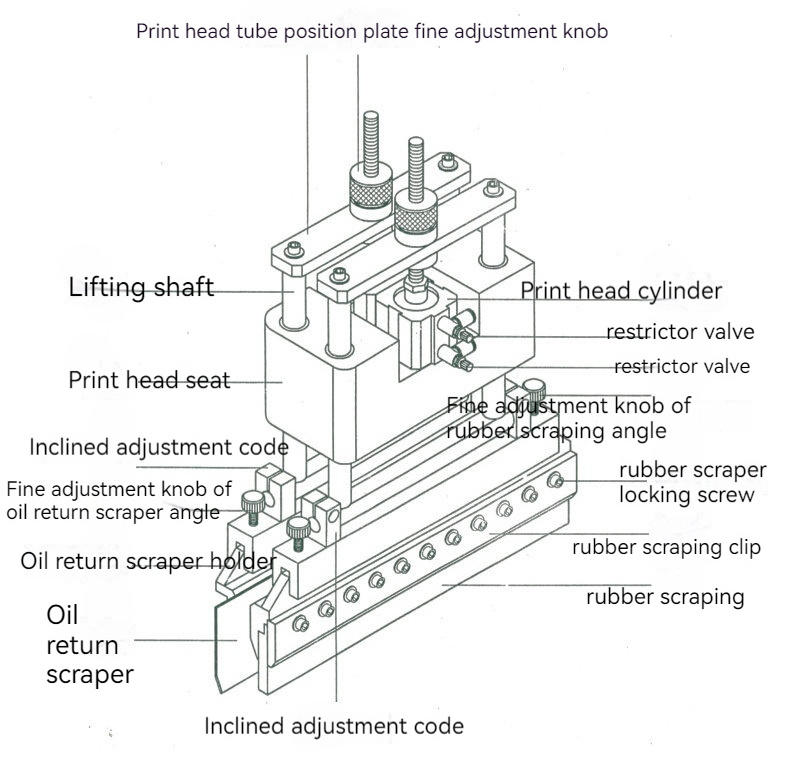

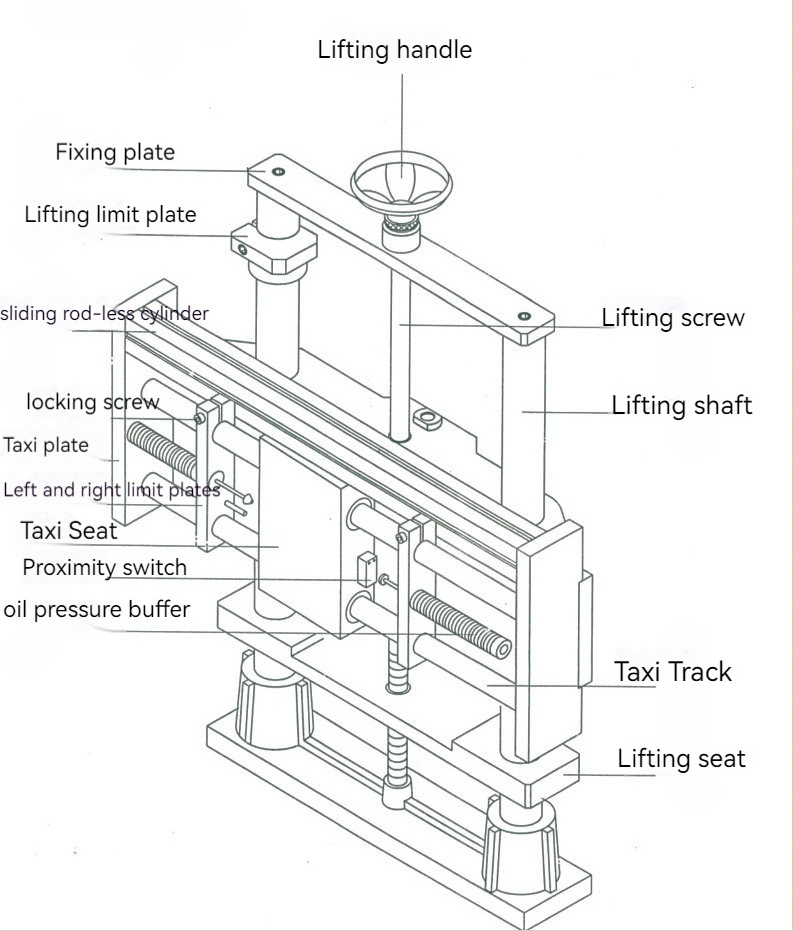

1. It adopts a combination of digital display and PLC control, with a stepper motor for material pulling and positioning, combined with high-precision and high-definition human-machine interface operation, which is simple and easy to understand.

2. Imported stepper drive pulling material is used in conjunction with a power adjustment device to ensure consistent tension and tension. The feeding operation is more stable, avoiding scratches and improving printing quality.

3. The printing scraper drive adopts synchronous PLC control, ensuring stable scraping speed and force, thereby ensuring the uniformity of the printing ink layer.

4. Adopting synchronous off screen function, effectively preventing screen sticking when printing large areas of background color or printing glue. Equipped with 4 rubber rollers at the same time, effectively cleaning the surface of the printed product.

5. Adopting a closed vertical oven with good insulation performance, maintaining constant temperature to save energy and reduce power consumption. Both are equipped with a drying function, allowing different printing processes to choose different drying methods.

6. Adopting a magnetic powder tension winding device, making it easy to roll and fold the material, with neat and stable edges.

Details Images

Marketing Campaign

Why Choose Us

Recommend Products

FAQ

Hot Searches