- Product Details

- {{item.text}}

Quick Details

-

Flling range:

-

2-14ml(Adjustable)

-

Filling nozzles:

-

12

-

Filling speed:

-

7-13model/min (84-156pcs/min)

-

Filling accuracy:

-

±0.1g

-

Tank volume:

-

20L(double-layer tank heated by oil)

-

Filling machine material:

-

304 & 316 stainless steel

Quick Details

-

Packaging Material:

-

Wood

-

Place of Origin:

-

Guangdong, China

-

Product name:

-

Lipstick making machine

-

Flling range:

-

2-14ml(Adjustable)

-

Filling nozzles:

-

12

-

Filling speed:

-

7-13model/min (84-156pcs/min)

-

Filling accuracy:

-

±0.1g

-

Tank volume:

-

20L(double-layer tank heated by oil)

-

Filling machine material:

-

304 & 316 stainless steel

Click here for more information !!!

Click here for more information !!!

Lipstick making machine

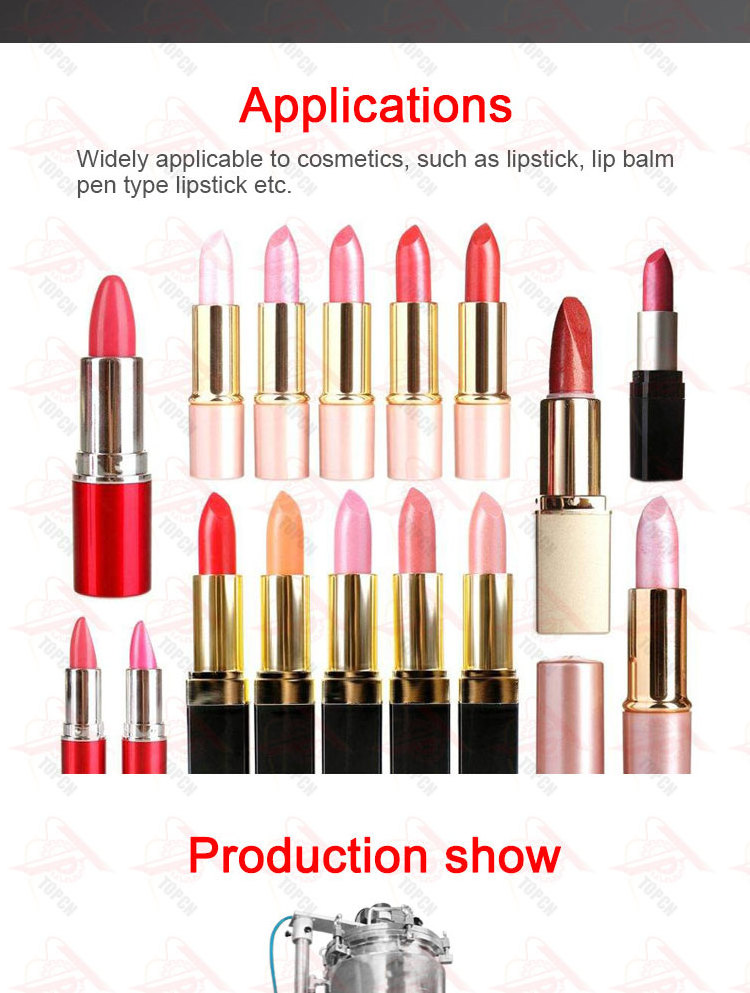

most commonly applicable for cosmetics, such as lipstick, lip balm, pen type lipstick etc.

1.

lipstick machine

2.

lip balm filling machine

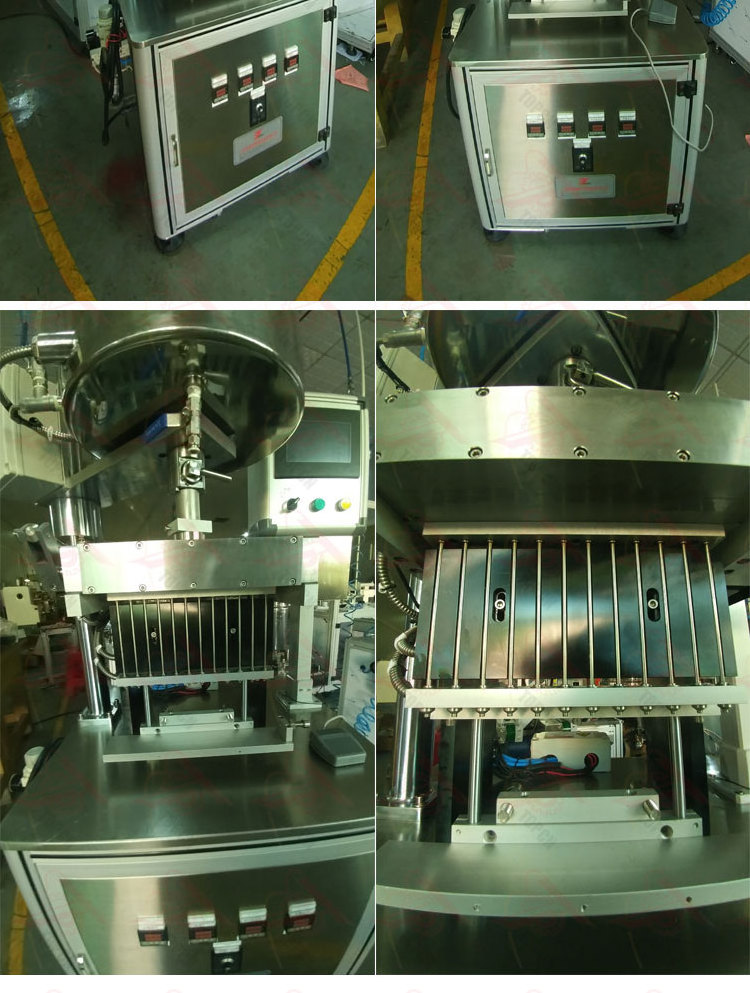

Technology Parameters

Lipstick preheating machine (for 12 seats molds)

|

Lifting Cylinder |

Control the heat blower system to move up and down |

|

Heat Gun |

Heat Device |

|

Control Panel |

A. Power Switch: control Power On/Off B. Lifting Cylinder(Manual/Auto): turn to Manual mode to adjust the position of Heat Gun when changing the mold. After finish the setting, turn to Auto mode to run the machine automatically. C. Delay to move down: the time Setting of delay the Heat Gun to move down. To avoid the machine hurt the hand of operator, the heat gun should not move down when change the mold, so have to set a delay time to ensure safety in production. Delay time could be set base on the time of operator change the mold. D. Heating up time: the time setting of heating up mold. |

Cooling Machine(7.5Hp)

|

Power Consumption |

7.5Hp |

|

Power |

AC 380 V/1ψ /50HZ |

|

Number of Machine Door |

4 |

|

Conveyor |

L3500*W2500*H1200mm |

|

Conveyor Belt Traveling Speed |

800mm/min |

|

Cooling time |

about 3-4 minutes |

|

Blow Type |

Downward blow |

|

Material of Machine Stainless Steel |

SUS304 |

|

Cooling |

-15℃ |

Lipstick Vacuum Blowing (for 12 seats molds)

|

Capacity |

30-50 lipsticks/min (depend on the mold type) |

|

Types |

Soft rubber mold by vacuum |

|

Dimensions |

650*520*1500 (mm) |

|

Body material |

T651+SUS304 |

|

Voltage |

AC220V/50Hz |

|

Weight |

70kg |

|

Operation |

1 operator |

1. DELIVERY LEAD TIME:

30-35 WORKING DAYS FOR THE AUTOMATIC MACHINE AFTER RECEIVED DEPOSIT

2.TERMS OF PAYMENT:

BY 30% IN ANVANCED, THE BALANCE 70% BY T/T BEFORE SHIPMENT

3.PRICE VALID UNTIL:

15-20DAYS.

4. PACKING:

WOODEN WITH STRONG SEAWORTHY PACKING SUITABLE FOR EXPORT

5.PORT OF SHIPMENT:

GUANGZHOU or SHENZHEN PORT

1.WARRANTY

The SELLER WARRANTY THE MACHINE FOR ONE YEAR, AND SUPPLY ONE YEAR FREE SPARE PARTS WITH THE MACHINE.

2.TERMS FOR INSTALLATIONS,STARTING-UP AND ADJUSTMENT.

THE SELLER SHOULD SEND ENGINEERS TO CARRY OUT INSTALLATION AND DEBUGGING OF THE EQUIPMENT IN BUYER’S PLACE IF REQUESTED. THE COST FOR INTERNATIONAL DOUBLE WAYS AIR TICKETS SHALL BE PAID BY BUYER FOR THE ENGINEER. BUYER SHALL

COOPERATE WITH SUPPLIER’S ENGINEER AND MAKE ALL THE INSTALLATION CONDITION READY TO WORK. SUCH AS”WATER, ELECTRICITY,RAW MATERIAL ETC.

3.OPERATION MANUAL

THE OPERATION MANUL WILL BE SHIPPED WITH THE GOODS AND IN ENGLISH VERSION.