Stamping is mainly classified according to process, which can be divided into two categories: separation process and forming process. The separation process is also called punching, and its purpose is to separate the stamping parts from the sheet material along a certain contour line, while ensuring the quality requirements of the separation section. The purpose of the forming process is to make the sheet plastically deform without breaking the blank to make a workpiece of the desired shape and size. In actual production, multiple processes are often applied to a workpiece. Punching, bending, shearing, drawing, bulging, spinning and straightening are just a few of the main stamping processes.

The surface and internal properties of the stamping sheet material have a great influence on the quality of the stamped product, requiring accurate and uniform thickness of the stamping material; smooth surface, no spots, scars, scratches, surface cracks,

etc.; uniform yield strength, no obvious Directionality; high uniform elongation; low yield ratio; low work hardening.

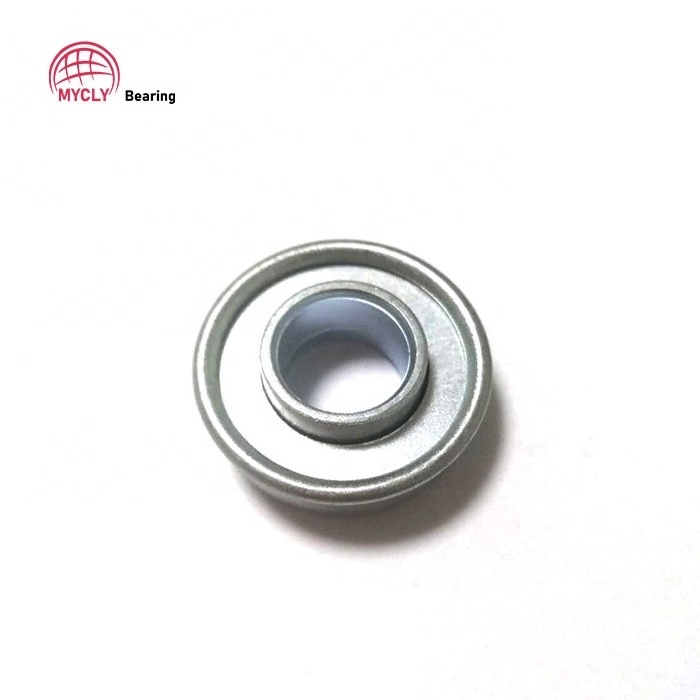

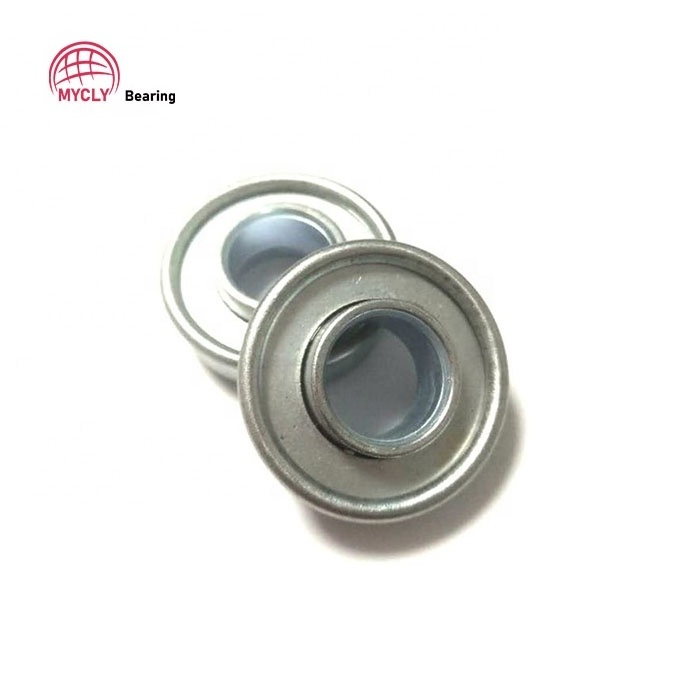

Application:children’s bicycles,bags and suitcases,Carrier rollers,Convery rollers,Wheel chair,Lawn mower etc