The thick T2 standard copper tube is taken use for induction coil.

- Product Details

- {{item.text}}

Quick Details

-

Voltage:

-

3x380V and 3x660V

-

Dimension(L*W*H):

-

Customized

-

Weight (T):

-

0.45 T

-

Power (kW):

-

100-2000

-

Furnace Body Material:

-

Aluminium Shell or Iron Steel Shell

-

Transformer:

-

Available to supply

-

Cooling Tower System:

-

Available to supply

-

Dust-remover System:

-

Available to supply

-

Melting Raw Material:

-

Steel, Stainless Steel, Recycled Steel, Scrap Steel, Steel Pipe

-

Automatic dumping System:

-

Available or Customized

-

Steel Furnace Capacity:

-

100kg 250kg 500kg 1t 2t

-

Turn Key Project:

-

Available to supply the complete plants from A to Z

-

Installation and Debugging:

-

Available

-

Weight:

-

0.5T-1.6T

Quick Details

-

Place of Origin:

-

Henan, China

-

Core Components:

-

Furnace

-

Brand Name:

-

HONGTENG

-

Voltage:

-

3x380V and 3x660V

-

Dimension(L*W*H):

-

Customized

-

Weight (T):

-

0.45 T

-

Power (kW):

-

100-2000

-

Furnace Body Material:

-

Aluminium Shell or Iron Steel Shell

-

Transformer:

-

Available to supply

-

Cooling Tower System:

-

Available to supply

-

Dust-remover System:

-

Available to supply

-

Melting Raw Material:

-

Steel, Stainless Steel, Recycled Steel, Scrap Steel, Steel Pipe

-

Automatic dumping System:

-

Available or Customized

-

Steel Furnace Capacity:

-

100kg 250kg 500kg 1t 2t

-

Turn Key Project:

-

Available to supply the complete plants from A to Z

-

Installation and Debugging:

-

Available

-

Weight:

-

0.5T-1.6T

We are factory(

more than 15years experiences

) located in Luoyang, Henan provice, China.

We are a professional manufacturer of

Industrial electric furnace, Ingot casting line, Hot rolling mill and CCM

.

We can provide a total solution according to your request.

We can provide

CE Certificate

,

Overseas installation

and

After-sales

service.

You are welcome to

send us enquiry

or to visit our factory.

Product Description

Technologicalt Process

The medium frequency smelting furnace mainly used for melting and refining all kinds of scrap metal, iron, stainless steel, copper, aluminum. This furnace can smelting the scrap iron, like scrap auto parts, scrap steel bars, scrap screws, iron leftover materials etc.

Product Features

1. Various capacity 0.1T -20T, fast melting speed, 40-60 minutes /pot

2. Have self-test function, real-time supervise.

3. Have leaking alarm device, PLC control, easy to operate.

4.The control cabinet is standard of the automobile line, easy to maintain

5. The water way uses carbon-free hose , water separetors and clips use 304 stainless steel

6.Can meet 24 hours continuous work.

7. High efficiency , low cost , easy to maintain, energy saving ,safe and stability.

Products Parts Display

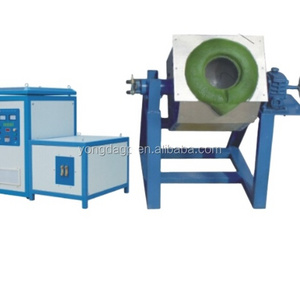

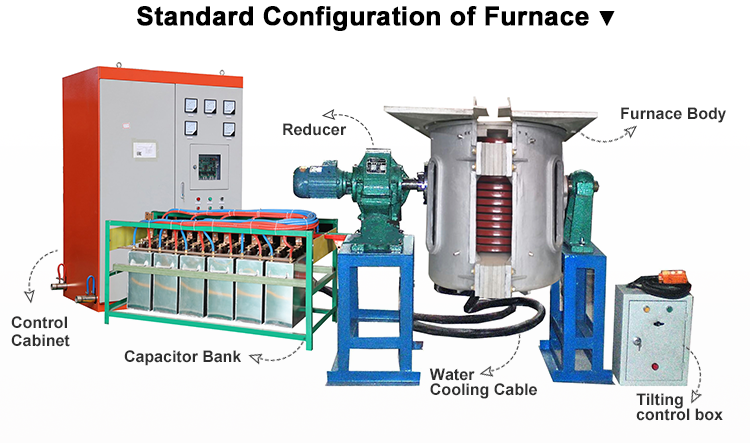

The melting furnace mainly composed of power control cabinet and melting furnace body.

The equipment can meet 24 hours of continuous work,

it have self-test function and leaking alarm device,

real-time detection of water temperature, water pressure, over-current, over-voltage, lack phase information.

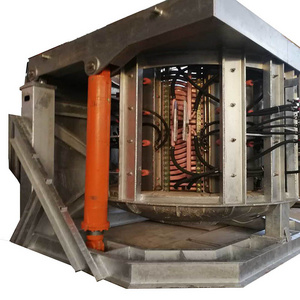

The furnace body is made by thick aluminum alloy shell to reduce the magnetic leakage and ensure furnace body strength.

The main control board is microcomputer control, one - key zero - pressure start.

The separate insolation design of water pressure meter can make the user convenient and intuitive to monitor the water pressure

The double-layer mica insulation technology is used for the insulation treatment of the capacitor.

Even if water is sprayed on the capacitor accidentally, the insulation strength of the cabinet can be ensured.

Furnace Tilting Reducer is used to control the rotary of the furnace body.

The tilting reducer is equipped with three-stage turbine speed. With good self-locking and stable rotary performance.

|

Basic Parameters

|

|

|

|

|

|

|

||||||

|

Capacity

|

Power

|

Voltage

|

Cabinet size (mm)

|

Cabinet weight

|

Furnace Body weight

|

|

||||||

|

100KG

|

100KW

|

3*380V

|

1000*800*1700

|

0.5T

|

0.3T

|

|

||||||

|

250KG

|

250KW

|

3*380V

|

1300*850*2000

|

0.8T

|

0.7T

|

|

||||||

|

500KG

|

400KW

|

3*380V

|

1300*850*2000

|

1T

|

1T

|

|

||||||

|

1T

|

800KW

|

3*660V

|

1300*850*2000

|

1.2T

|

1.3T

|

|

||||||

|

1.5T

|

1000KW

|

3*660V

|

1300*850*2000

|

1.2T

|

1.8T

|

|

||||||

|

2T

|

1500KW

|

3*660V

|

2400*1000*2000

|

1.6T

|

2T

|

|

||||||

|

5T

|

3000KW

|

6*950V

|

2400*1000*2000

|

2.5T

|

4.5T

|

|

||||||

|

10T

|

6000KW

|

6*1250V

|

3500*1000*2200

|

3T

|

23T

|

|

||||||

|

15T

|

10000KW

|

6*1250V

|

4000*1200*2200

|

3.5T

|

32T

|

|

||||||

Recommend Products

Why Choose Us

Certifications

Hot Searches