- Product Details

- {{item.text}}

Quick Details

-

Place of Origin:

-

Henan, China

-

Brand Name:

-

STA

-

Dimension(L*W*H):

-

100*100*100 MM

-

Weight:

-

2 KG

-

After-sales Service Provided:

-

Overseas service center available

-

Color:

-

White

-

Size:

-

Customer's Requirements

-

MaxTemperature:

-

1200 ( C)

-

Advantage:

-

Energy-saving

-

Other application:

-

High Heat Equipments

-

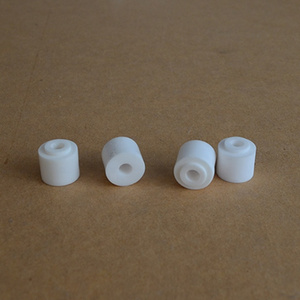

Product name:

-

Alumina ceramic heater, furnace chamber,ceramic fiber heating module

-

Package:

-

wooden box

-

Marketing Type:

-

New Product 2024

Quick Details

-

Type:

-

Duct Heater

-

Power Source:

-

Electric

-

Voltage:

-

220V

-

Place of Origin:

-

Henan, China

-

Brand Name:

-

STA

-

Dimension(L*W*H):

-

100*100*100 MM

-

Weight:

-

2 KG

-

After-sales Service Provided:

-

Overseas service center available

-

Color:

-

White

-

Size:

-

Customer's Requirements

-

MaxTemperature:

-

1200 ( C)

-

Advantage:

-

Energy-saving

-

Other application:

-

High Heat Equipments

-

Product name:

-

Alumina ceramic heater, furnace chamber,ceramic fiber heating module

-

Package:

-

wooden box

-

Marketing Type:

-

New Product 2024

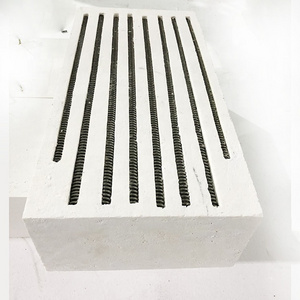

STA 1200C Alumina ceramic heater, furnace chamber,ceramic fiber heating module

Alumina ceramic fiber has several types: 1200 type, 1400 type, 1600 type ,1800 type and 1900 type.

ceramic fiber board is a lightweight refractory material processed with alumina-silica fibers for applications at temperatures up to 1800C. it manufactured and designed for the thermal applications requesting high demands on rigidity, the thermal insulation properties and abrasion resistance of ceramic fiber board have been further improved due to the higher density. Ceramic fiber board is a vacuum formed product that resists higher gas velocities than ceramic fiber blanket. It is ideal for furnace, boiler duct and stack lining thanks to its low thermal conductivity and low heat storage, which makes the shorter cycles times and quicker access for maintenance in the industrial furnaces possible.

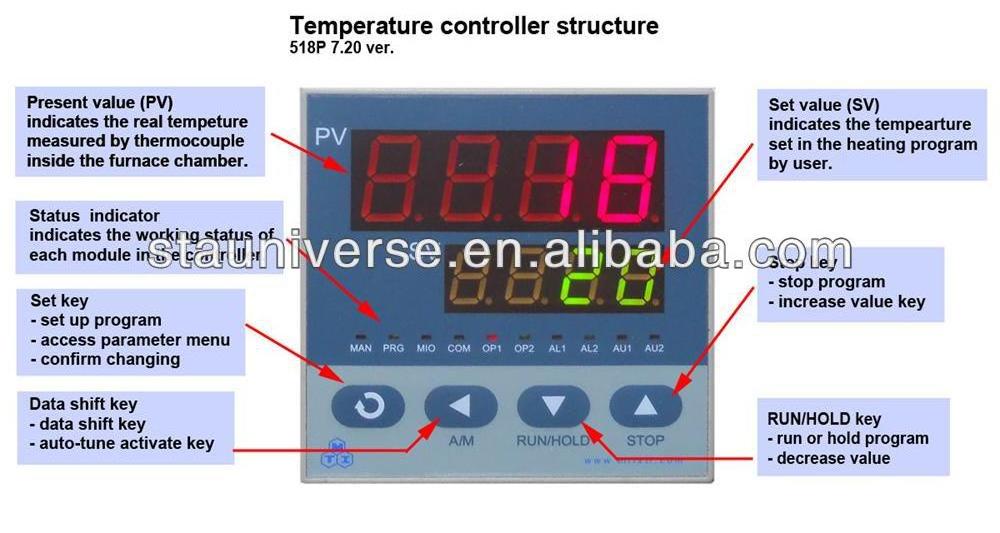

Industry demands quality and high performance technology in control process heating. Working in cooperation with our customers, we provide it in a number of new products. We originally pioneered the use of conventional components in unique ways to create products for an ever demanding market and we still do.

100% Inorganic

Cost Effective

Custom Designs

Vacuum Formed

18 PCF Density

Low Thermal Conductivity

High Thermal Shock Resistance

Foundry Service

An extensive array of ceramic fiber heaters is offered in almost all sizes, shapes and temperature ranges. Vacuum formed heaters can provide a practical and economical solution to both R&D and production quantity requirements. Consult us for both custom and standard configurations.

Ceramic Fiber Panel Heaters

Characteristics:

1600C Rated

Fast Response

Low Thermal Conductivity Insulation

100% Inorganic

Available Options

Black Body Coating for Greater Uniformity

Thermocouple Hole

1700 C Rating.

Special Lead Types

Embedded/Recessed Element

Stepped Borders

Ceramic Fiber Semi-Cylindrical Heaters

Characteristics:

1600C Rated

Fast Response

Low Thermal Conductivity Insulation

100% Inorganic

Available Options

Black Body Coating for Greater Uniformity

Thermocouple Hole

1700 C Rating.

Special Lead Types

Embedded/Recessed Element

Stepped Borders

Ceramic Fiber Full-Cylindrical Heaters

Characteristics:

1600C Rated

Fast Response

Low Thermal Conductivity Insulation

100% Inorganic

Available Options

Black Body Coating for Greater Uniformity

Thermocouple Hole

1700 C Rating.

Special Lead Types

Embedded/Recessed Element

Stepped Borders

STA offers a complete line of custom made high temperature heaters, for all your process needs.

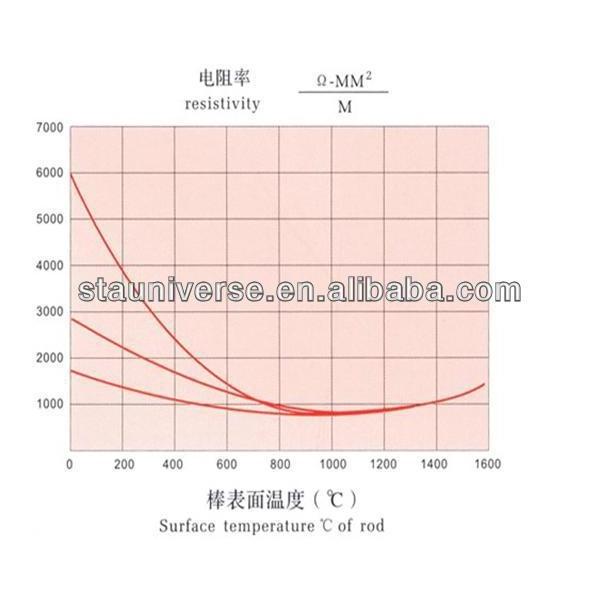

Ceramic fiber heater Molybdenum Disilicide Heating elements:

1750 Celsius Maximum Operating Temperature in Air

1600 Celsius Maximum Operating Temperature in Nitrogen, Argon or Helium

1450 Celsius Maximum Operating Temperature in Hydrogen Atmospheres

Excellent resistance to oxidation at temperatures above 1200 C.

Available in Cylindrical, Split Tube and Rectangular Configurations

Limited Complete Furnace Manufacturing (upon request)

Applications include semiconductor production, gem production, laboratory and research, annealing, sintering, heat treating, metal melting

Ceramic fiber heater with Silicon Carbide Heating elements:

1500 Celsius Maximum Operating Temperature in Air

1600 Celsius Maximum Operating Temperature in Nitrogen, Argon or Helium

1450 Celsius Maximum Operating Temperature in Hydrogen Atmospheres

Excellent resistance to oxidation at temperatures above 1200 C.

Available in Cylindrical, Split Tube and Rectangular Configurations

Limited Complete Furnace Manufacturing (upon request)

Applications include semiconductor production, gem production, laboratory and research, annealing, sintering, heat treating, metal melting

Furnaces can be configured to operate at 208 or 240 line voltage in single or three phases

Type of STA Insulation fiber heater and recommend loading:

Generally, our warranty is one year. Within the warranty period, we can offer technique support, Feedback to you within 12 hours and help you to settle your problem controller freely.

1.Do you have MOQ of goods?

We accept the trial order, so you can test quality firstly.

2.Can you offer best price for us to beat competitors?

Of course, we can update price to support your business.

3.How long will it take to complete my order?

For the stock items, we can arrange the shippment within 2 days after paymment is received. For the customized items,lead time is about 25 days.

4.What's your after-sales service?

Furnaces is 2 years warranty, other products is 3 months.

5. Can you send goods to our shipping agent in China?

YES, We can. And delivery time is within 3 days.

6. Can we visit your factory?

We are so happy to get your visit.