- Product Details

- {{item.text}}

Quick Details

-

detergent powder:

-

detergent powder making machine

-

International authentic action:

-

ISO9001,BV etc international professional orgnaization

-

Integrated design:

-

civil work,electrical,instrumentation,automation,equipment fabricate

-

Core competency:

-

we have leading world's advanced technology innovation ability

-

Technique:

-

environment protection

-

Commission:

-

professional service

-

Plants Advantage::

-

Manual or fully automatic computer controlled system

-

Capacity of the plants::

-

3,000 t/a to 200,000 t/a

-

Operation mode::

-

manually and computer controlled

-

Environmental impact::

-

no wastewater is drained to outside.

Quick Details

-

Place of Origin:

-

Zhejiang, China

-

Brand Name:

-

Aisa Chemical

-

Weight (KG):

-

3500

-

detergent powder:

-

detergent powder making machine

-

International authentic action:

-

ISO9001,BV etc international professional orgnaization

-

Integrated design:

-

civil work,electrical,instrumentation,automation,equipment fabricate

-

Core competency:

-

we have leading world's advanced technology innovation ability

-

Technique:

-

environment protection

-

Commission:

-

professional service

-

Plants Advantage::

-

Manual or fully automatic computer controlled system

-

Capacity of the plants::

-

3,000 t/a to 200,000 t/a

-

Operation mode::

-

manually and computer controlled

-

Environmental impact::

-

no wastewater is drained to outside.

Products Description

|

item

|

value

|

|

Type

|

Detergent

|

|

Place of Origin

|

China

|

|

Active ingredient content

|

-

|

|

detergent powder

|

detergent powder making machine

|

|

International authentic action

|

ISO9001,BV etc international professional orgnaization

|

|

Integrated design

|

civil work,electrical,instrumentation,automation,equipment fabricate

|

|

Core competency

|

we have leading world's advanced technology innovation ability

|

|

Technique

|

environment protection

|

|

Commission

|

professional service

|

|

design installation

|

professional service

|

|

Machine Type

|

DPMM-100

|

Plants Advantage:

Manual or fully automatic computer controlled system, meet customer’s requirements

Capacity of the plants: 3,000 t/a to 200,000 t/a

Operation mode: manually and computer controlled

Supply range: from renovation of existing plant to totally new plants.

Environmental impact: no wastewater is drained to outside.

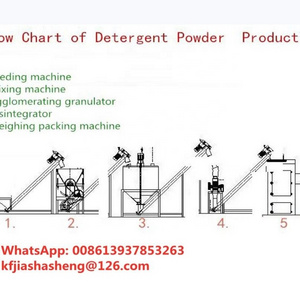

Description of the processes

1.Complete detergent powder plant with spray drying tower

Raw materials in form of powder and liquid are dosed accurately, and then are sent to neutralization and ageing system to be neutralized and aged. The process stream in form of slurry now goes through a milling-homogenizing pump to be homogenized. After that the slurry is then fed to the spray-drying tower to form hollow beads with bulk density of 0.20 to 0.35 kg/L, granulation size of 0.5 to 1.5 mm. After sieved and conditioned in an airlift system, the powder becomes the base powder of low bulk density. A post-addition unit can be provided according to customer’s requirements, where perfume, enzyme, perborate are mixed to the base powder to yield medium- or high-grade detergent powder.

2.Concentrated detergent powder plant with agglomerator

Solid raw materials in form of powder are sieved and premixed, then stored in respective silos. The solid materials are weighed accurately by dosing belts according to the detergent powder formulation, and fed to the agglomerator. While the liquid raw materials are dosed accurately by dosing pumps and fed to the agglomerator in form of sprayed particles. The agglomeration product from its bottom is fed to a fluidizing bed to remove free water in the particle’s surface and form crystal water in the powder to increase its added value. Perfume, enzyme and other minor ingredients are added into this powder in post-addition unit to obtain final high-grade product with bulk density of 0.45 to 0.8 kg/L, waiting to be packed.

3. Central control room with computers

a. The whole plant is automatically controlled by PLC

b. The startup and shutdown of the plant is controlled by programs in the computers.

c. There are interlocks between critical items of equipment, and monitoring of operation data.

d. The functions of the system include detergent powder formulation adjustment; report printout, operation data display and recording/filing.

e. Big screen showing how the plant is running. There are also alarmings and operator intervene indications.

f. Manual and automatic operation modes can be switched between each other by operator.

g. All raw materials, both solid and liquid, are automatically dosed according to detergent powder formulation by computer.

4. Tower-Agglomerator Plant

This plant can produce both low -density and high-density detergent powders in the bulk density range of 0.28 to 0.7 kg/L. Energy is saved tremendously because 70% of the raw materials are added by agglomeration system.

5. Post-addition Unit

Base powder and minor solid ingredients, such as enzyme, and sodium perborate, etc., are dosed by electronic dosing belts or vibration feeders, then fed into a post-addition rotating mixer. While the liquid ingredients, such as nonionic and perfume are fed into the mixer by dosing pumps and sprayed inside the mixer. The powders and liquids are adsorbed/mixed together, yielding a stably formulated and homogenized medium/high-grade product detergent powder waiting to be packed.

30% of materials in the product powder can be added by this post-addition unit.

Recommend Products

FAQ

1. who are we?

We are based in Zhejiang, China, start from 1997,sell to Mid East(66.50%),Southeast Asia(12.50%),North America(5.50%),Eastern Asia(4.00%),South America(4.00%),Africa(3.50%),Oceania(2.00%),Eastern Europe(2.00%). There are total about 51-100 people in our office.

2. how can we guarantee quality?

Always a pre-production sample before mass production;

Always final Inspection before shipment;

3.what can you buy from us?

Detergent Powder Plant,Chemical Complete Plant,Daily Chemical Machinery And Equipment,Inorganic Chemical Complete Plant,Chemical Raw Material Manufacturer

4. why should you buy from us not from other suppliers?

Asia Chemical is committed to household chemicals, basic chemicals, petroleum and natural gas and other fields. Core competencies have new technology development capabilities, design capabilities, international engineering management and customer service.

5. what services can we provide?

Accepted Delivery Terms: FOB,CFR,CIF;

Accepted Payment Currency:USD,EUR;

Accepted Payment Type: T/T,L/C;

Language Spoken:English,Chinese

We are based in Zhejiang, China, start from 1997,sell to Mid East(66.50%),Southeast Asia(12.50%),North America(5.50%),Eastern Asia(4.00%),South America(4.00%),Africa(3.50%),Oceania(2.00%),Eastern Europe(2.00%). There are total about 51-100 people in our office.

2. how can we guarantee quality?

Always a pre-production sample before mass production;

Always final Inspection before shipment;

3.what can you buy from us?

Detergent Powder Plant,Chemical Complete Plant,Daily Chemical Machinery And Equipment,Inorganic Chemical Complete Plant,Chemical Raw Material Manufacturer

4. why should you buy from us not from other suppliers?

Asia Chemical is committed to household chemicals, basic chemicals, petroleum and natural gas and other fields. Core competencies have new technology development capabilities, design capabilities, international engineering management and customer service.

5. what services can we provide?

Accepted Delivery Terms: FOB,CFR,CIF;

Accepted Payment Currency:USD,EUR;

Accepted Payment Type: T/T,L/C;

Language Spoken:English,Chinese

Hot Searches