<1> 304/316 Stainless steel high precision filling nozzle

<2> Filling volume adjustable in fine rank, same liquid level after filling

<3> All 304/316 stainless steel contact parts & liquid tank, fine polish, no death corner, easy to clean

<4> 304/316 stainless steel filling pump

<5>Efficient spray nozzle rinse thoroughly and save water for flushing

- Product Details

- {{item.text}}

Quick Details

-

Filling Accuracy:

-

±1ml

-

Voltage:

-

220V/380V(by order)

-

Place of Origin:

-

Jiangsu, China

-

Brand Name:

-

V APCK

-

Dimension(L*W*H):

-

35700*3200*28500mm

-

Weight:

-

4200 KG

-

Name:

-

Bottle Liquid Filling Machine

-

Control:

-

Electricity Control

-

Keywords:

-

Drinking Water Production Plant

-

Machine material:

-

Stainless Steel SUS 304/316

Quick Details

-

Machinery Capacity:

-

4000BPH, 8000BPH, 12000BPH, 6000BPH, 20000BPH, 16000BPH

-

Packaging Material:

-

Plastic

-

Filling Material:

-

Beer, Other, Juice

-

Filling Accuracy:

-

±1ml

-

Voltage:

-

220V/380V(by order)

-

Place of Origin:

-

Jiangsu, China

-

Brand Name:

-

V APCK

-

Dimension(L*W*H):

-

35700*3200*28500mm

-

Weight:

-

4200 KG

-

Name:

-

Bottle Liquid Filling Machine

-

Control:

-

Electricity Control

-

Keywords:

-

Drinking Water Production Plant

-

Machine material:

-

Stainless Steel SUS 304/316

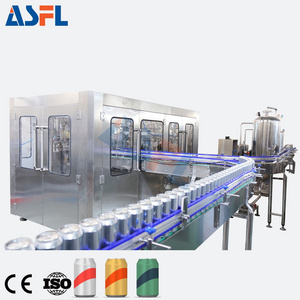

Main Machine in Can juice/csd drink filling packing production plant/ line.

1/Preparing System

2/Water Treatment Syatem

3/Empty can unloading machine

4/Slide - type empty tank spray washer

5/Can juice/csd drink filling sealing 2 in 1 monoblock

6/Spray sterilizing chiller (including local control cabinet and electrical control device)

7/Wrapping machine

2/Water Treatment Syatem

3/Empty can unloading machine

4/Slide - type empty tank spray washer

5/Can juice/csd drink filling sealing 2 in 1 monoblock

6/Spray sterilizing chiller (including local control cabinet and electrical control device)

7/Wrapping machine

Filling heads.

Capping heads.

<1> Place and capping system, electromagnetic capping heads, with burden discharge function, make sure minimum bottle crash during

capping

<2> All 304/316 stainless steel construction

<3> No bottle no capping

<4> Automatic stop when lack of bottle

<5>Capping effect is stable and reliable ,Defective rate ≤0.2% .

capping

<2> All 304/316 stainless steel construction

<3> No bottle no capping

<4> Automatic stop when lack of bottle

<5>Capping effect is stable and reliable ,Defective rate ≤0.2% .

Flat conveyor.

Flat conveyor.

1/Energy saving. High efficient. Adapt to customer factory layout

2/Special lubrication system, keep products clean, health, safety

3/Extended service life

4/Electric eyes design keep whole line running safety and quickly

5/Overload protection mechanism to effectively ensure the safety of the machine

1/Energy saving. High efficient. Adapt to customer factory layout

2/Special lubrication system, keep products clean, health, safety

3/Extended service life

4/Electric eyes design keep whole line running safety and quickly

5/Overload protection mechanism to effectively ensure the safety of the machine

Auxiliary Equipment

Nitrogen dosing machine

Nitrogen injection machine design for Aluminium can and PET bottle(low weight preform).

This liquid nitrogen injection system adopts the heat insulation like rocket and human-machine interface. Precisely injection.

This liquid nitrogen injection system adopts the heat insulation like rocket and human-machine interface. Precisely injection.

Filling liquid level detector

The principle that the intensity of rays varies with the position

of the material surface to control the capacity of liquid material to be tested and filled because of its non-contact measurement.It solves the problem that the conventional weighing

method can not measure the volume of liquid material on production ine.

of the material surface to control the capacity of liquid material to be tested and filled because of its non-contact measurement.It solves the problem that the conventional weighing

method can not measure the volume of liquid material on production ine.

Empty can unloading machine.

This machine is based on the introduction of foreign advanced technology, combined with the new products developed after years of

production experience.

This machine design science is reasonable, modelling is beautiful.

Convenient operation and maintenance, high degree of automation.

This machine is mainly used in the unloading process of the can.

production experience.

This machine design science is reasonable, modelling is beautiful.

Convenient operation and maintenance, high degree of automation.

This machine is mainly used in the unloading process of the can.

Slide - type empty tank spray washer.

1/Scope of application: water spraying and drying on the slope of the tin can.

2/water spraying box made by stainless steel structure.

3/the built-in ¢32 mm stainless steel spray pipe, divide into two segments, hot and cold water tank temperature higher than 85

degrees.

4/tank cage, by ¢article 8 mm stainless steel.

5/the support frame is composed of 50mm x 50mm x 2mm stainless steel square pipe.

2/water spraying box made by stainless steel structure.

3/the built-in ¢32 mm stainless steel spray pipe, divide into two segments, hot and cold water tank temperature higher than 85

degrees.

4/tank cage, by ¢article 8 mm stainless steel.

5/the support frame is composed of 50mm x 50mm x 2mm stainless steel square pipe.

Spray sterilizing chille.

including local control cabinet and electrical control device

1/Mainly for cooling and sterilization

2/The main parts of the machine are made of stainless steel, the top is designed to be openable for easy maintenance and

observation

3/Nozzles are manufactured using U.S. technology and spray water evenly

4/Conveyor belt adopts Rexnor technology, flat surface with small w ear

1/Mainly for cooling and sterilization

2/The main parts of the machine are made of stainless steel, the top is designed to be openable for easy maintenance and

observation

3/Nozzles are manufactured using U.S. technology and spray water evenly

4/Conveyor belt adopts Rexnor technology, flat surface with small w ear

Bottle packaging machine.

1/PE film shrink wrapping machine

2/Half-tray shrink wrapping machine

3/Carton box packaging machine

It adopts the photoelectric sensor to detect online, gather signals which are controlled by PLC, and adopts piston as executable

element, to realize product conveying, combination, film wrapping, cutting, heat& shrink, cool and finally get the finished

product.

2/Half-tray shrink wrapping machine

3/Carton box packaging machine

It adopts the photoelectric sensor to detect online, gather signals which are controlled by PLC, and adopts piston as executable

element, to realize product conveying, combination, film wrapping, cutting, heat& shrink, cool and finally get the finished

product.

Our Company

Packing & Delivery

Hot Searches