- Product Details

- {{item.text}}

Quick Details

-

Voltage:

-

Customized, customized

-

Dimension(L*W*H):

-

2000*800*1500

-

Year:

-

2024

-

Weight (KG):

-

1500 kg

-

Power (kW):

-

7.5

-

Applicable Industries:

-

Rubber machine, Tire related products, Automatic waste tire recycling machine, waste tyre recycling machine, rubber factory, rubber processing machinery

-

Name:

-

Tyre cutting machine

-

After-sales Service Provided:

-

Engineers available to service machinery overseas

-

Application:

-

waste tire recycling

-

capacity:

-

1500 kg/hour

-

End product:

-

rubber powder / fiber / steel

-

Labor required:

-

1-2

-

Adapt tire:

-

nylon tire , steel tire , truck tire

-

Usage of final product:

-

rubber tile , reclaimed rubber making ,rubber wheel

-

Type:

-

Automatic

Quick Details

-

Place of Origin:

-

Shandong, China

-

Brand Name:

-

OULI

-

Model Number:

-

TC-300

-

Voltage:

-

Customized, customized

-

Dimension(L*W*H):

-

2000*800*1500

-

Year:

-

2024

-

Weight (KG):

-

1500 kg

-

Power (kW):

-

7.5

-

Applicable Industries:

-

Rubber machine, Tire related products, Automatic waste tire recycling machine, waste tyre recycling machine, rubber factory, rubber processing machinery

-

Name:

-

Tyre cutting machine

-

After-sales Service Provided:

-

Engineers available to service machinery overseas

-

Application:

-

waste tire recycling

-

capacity:

-

1500 kg/hour

-

End product:

-

rubber powder / fiber / steel

-

Labor required:

-

1-2

-

Adapt tire:

-

nylon tire , steel tire , truck tire

-

Usage of final product:

-

rubber tile , reclaimed rubber making ,rubber wheel

-

Type:

-

Automatic

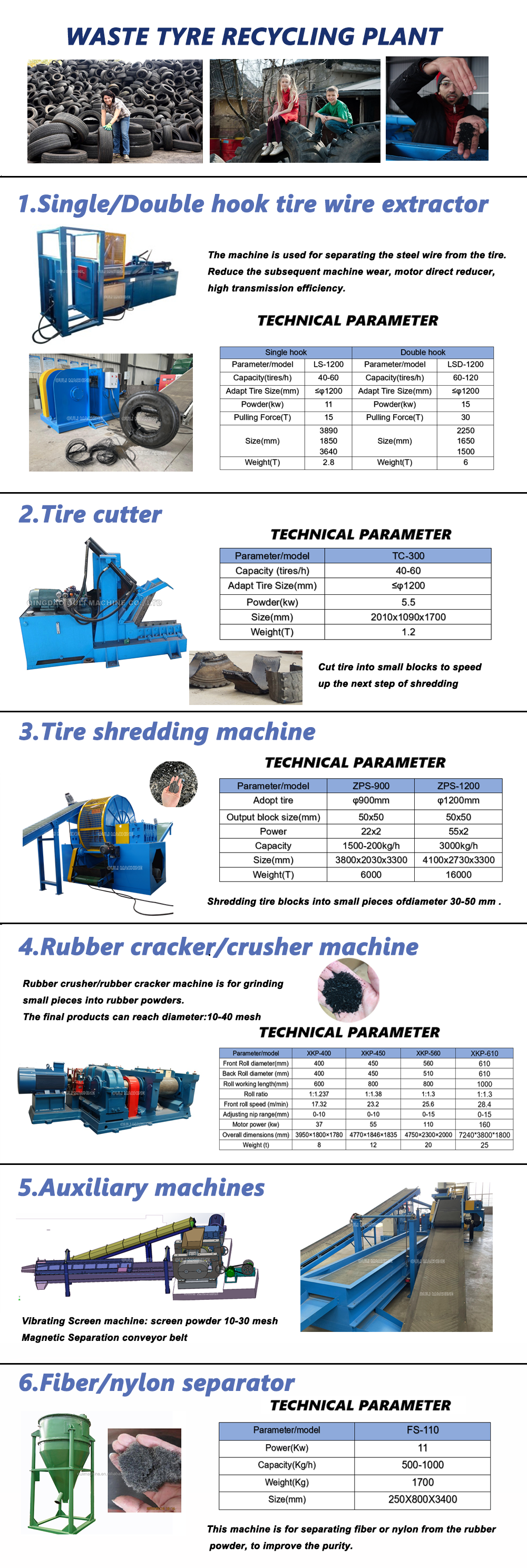

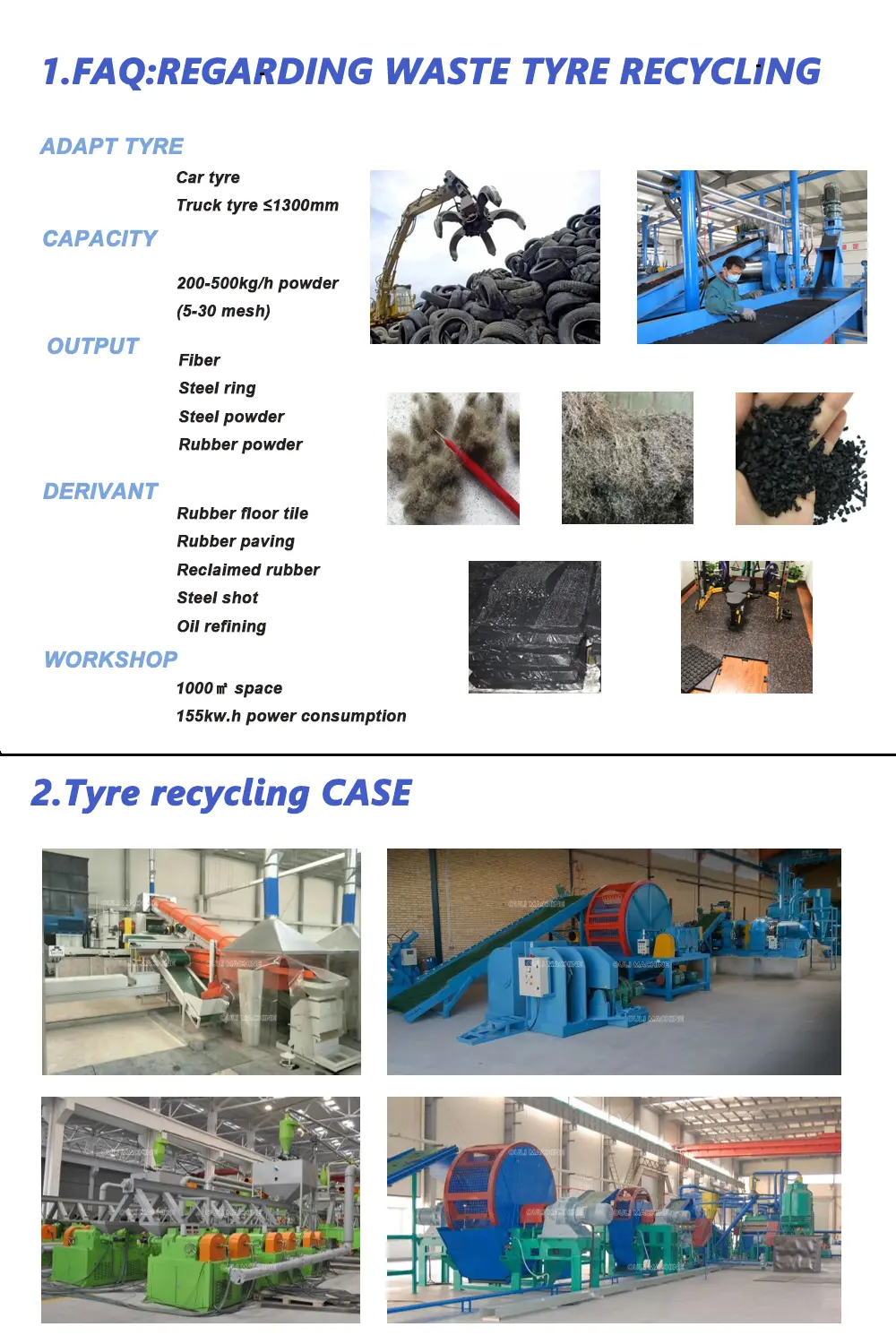

1 Products Description

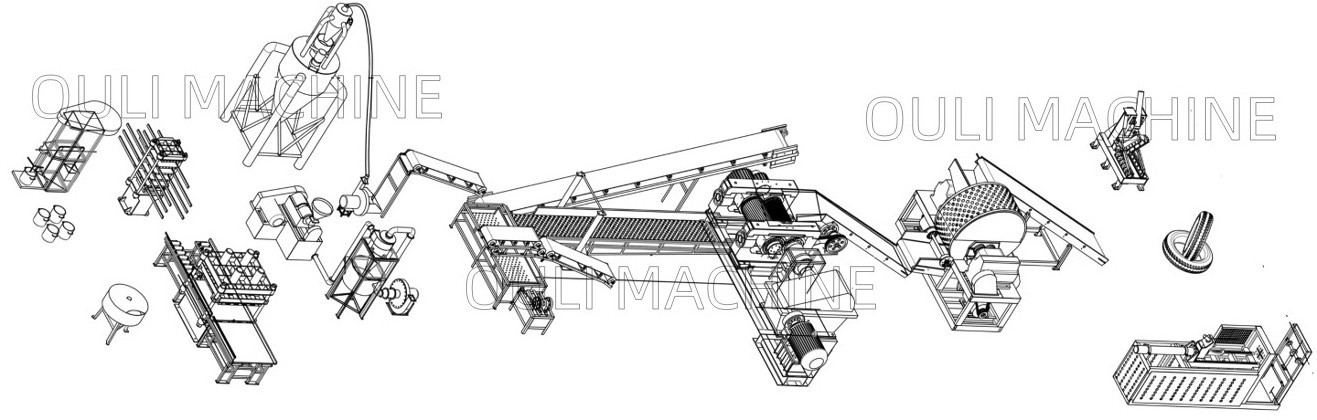

OULI waste tire rubber powder equipment: composed by the decomposition of waste tire powder crushing, screening unit composed of magnetic carrier. Through the decomposition of waste tire facilities, tire processing into small pieces, and then crushing mill of the rubber block, rubber powder to be mixed wire; then powder magnetic separator, the steel and rubber powder separated completely. Through the feeding device through two sieve beds filter out the fine material and then by magnetic roller, magnetic separation of a steel wire, Preparation of 10 mesh fineness of the purity of-40

me

s

h

powder(fineness optional).This processing technology,there is no air pollu-tion,no waste water,low operation cost.

lt is the best equip

ment to produce waste tire rubber

powder.

2 work procedure

3 other problems

4 Recommend Products

Hot Searches