- Product Details

- {{item.text}}

Quick Details

-

EINECS No.:

-

other

-

Place of Origin:

-

Zhejiang, China

-

Brand Name:

-

Magic Drip

-

Model Number:

-

DM-2118

-

Type:

-

Two-Component

-

Product name:

-

Epoxy Resin Crystal AB Glue

-

Color:

-

Clear

-

Application:

-

Casting

-

Volume:

-

15 kgs/1.5 gallons/3 gallons

-

Component:

-

2 Components

-

Mixing Ratio:

-

2:1

-

Curing time:

-

24h

-

Shelf life:

-

12 Months

-

OEM:

-

Support

-

Working Time:

-

60-90mins

Quick Details

-

CAS No.:

-

61788974

-

Other Names:

-

Wood Paint and Casting

-

MF:

-

(C11H12O3)n

-

EINECS No.:

-

other

-

Place of Origin:

-

Zhejiang, China

-

Brand Name:

-

Magic Drip

-

Model Number:

-

DM-2118

-

Type:

-

Two-Component

-

Product name:

-

Epoxy Resin Crystal AB Glue

-

Color:

-

Clear

-

Application:

-

Casting

-

Volume:

-

15 kgs/1.5 gallons/3 gallons

-

Component:

-

2 Components

-

Mixing Ratio:

-

2:1

-

Curing time:

-

24h

-

Shelf life:

-

12 Months

-

OEM:

-

Support

-

Working Time:

-

60-90mins

Products Description

Magic Drip

®

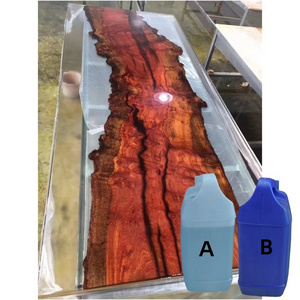

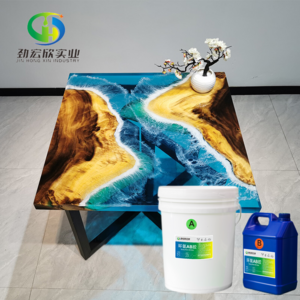

MD-2118 It is designed to be poured thick and works amazingly for filling and thick pours on very large voids in raw wood slab tops, such as river tables,side tables,coffee tables,benches,stools,

consoles,shelves,lamps,lights,big crafts and gifts etc.

MD-2118 DEEP Casting Epoxy resin is unique because normal casting resin can only be poured in thickness of 1/8" per coat but MD-2118 Casting resin can be poured up to 2"-4" thick depending on the size and mass of your project.

It is designed to be slow curing so the heat will not be generated and "over cook" the epoxy.

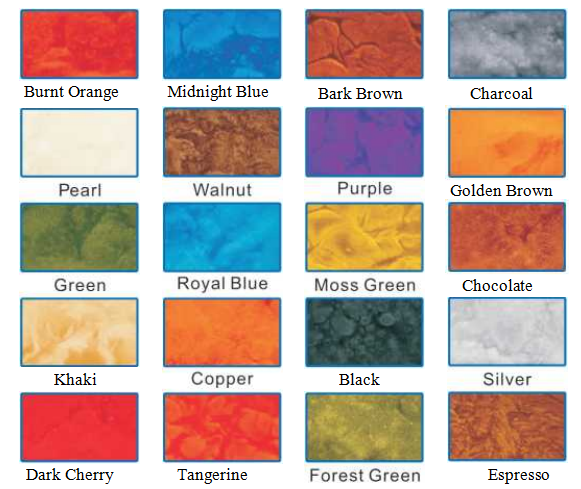

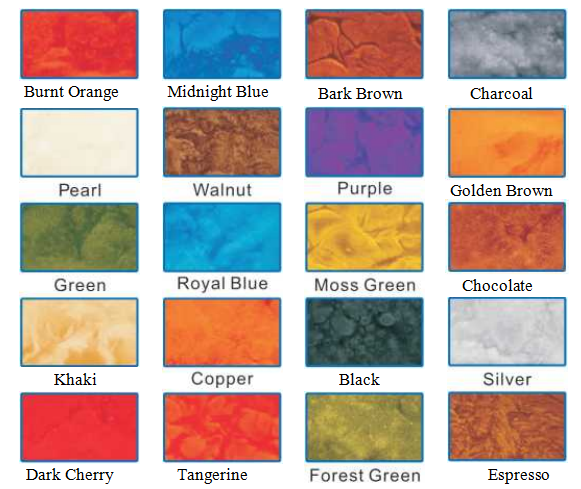

You can use the metallic powder additives, glitter, mica, or base color tints to color and tint our resin. With a longer cure time which can cause the metallic powders to settle, look softer and more toned down.

Product Paramenters

|

Item

|

Epoxy Resin(A)

|

Epoxy Resin(B)

|

|

|

Appearance

|

Liquid

|

Liquid

|

|

|

Color

|

Crystal Clear

|

Crystal Clear

|

|

|

Viscosity@25°C

(mpa.s) |

3000〜5000

|

300-600

|

|

|

Mix Ratio

|

2:1

|

|

|

|

Hardness (Shored D)

|

85 〜88

|

|

|

|

Solid Content

|

100%

|

|

|

|

Working Time

|

60 〜90mins@25°C

|

|

|

|

Curing Time

|

12-24hrs@25°C ,8-12 hrs@40°C

|

|

|

|

Full Cured Time

|

48hrs@25°C

|

|

|

|

Polished Time

|

48hrs@25°C

|

|

|

|

Shelf Life

|

12 Months

|

|

|

|

Package

|

1.5Gallons/unit,3gallons/unit,

15kgs/unit,accept OEM&ODM |

|

|

Product Features

•

Non-toxic

•

100% Solid

•Crystal Clear

•VOC Free

•Solvent Free

•

De-defoaming

•Thick Pour 2h in one time

Note

The following information is offered as a guide only to help eliminate some of those concerns,simplify and speed up the process.Read all instructions before proceeding and consider a test sample first to familiarize yourself with the process. If you have any questions,consider contacting us before starting.

INSTRUCTIONS:

1.IMPORTANT: Check the moisture content of each wood slab. To avoid warping and other moisture related issues, the moisture content of wood slabs should be 15% or less. If possible, use a moisture meter to check, or from the back of each slab drill small holes into the center of each wood piece. Use a 1/4 or similar size bit and immediately after drilling inspect the wood shavings for moisture. It would be advisable to check several areas of each slab. If wood shavings are just sightly moist, you should be ok to proceed. If shavings are wet, it would be advisable to allow the slabs to continue to dry in a warm,but not hot environment and away from direct sunlight. Depending on the thickness and type of wood, slabs can take two or more years to completely dry.

2. PREPARATION: Once the slabs are sufficiently dry, plane, level and sand the slab pieces as necessary. Remove all loose bark or glue in place. If using an adhesive to attach the bark, allow it to completely dry or cure before proceeding.

3. SEALING: All edges must be sealed to stop bubbles from escaping while filling voids with resin.Most hard and soft woods absorb resin readily and expel air as they do. This can create chimney like bubbles in the resin and can be difficult if not impossible to stop. To do so,elevate wood pieces if necessary,apply small amount of fast cure epoxy resin, and apply to all edges with a nylon disposable brush. Be gentle when applying so that the resin mixture does not become foamy with too much agitation. If it does, remove this material with a lint free cloth moistened lightly with Isopropyl alcohol and reapply. Once all edges are coated with a thin layer(no build), just enough product to wet the surface,allow the resin to set for 8 hours. Repeat this process until all edge surfaces have a slight glossy appearance. Flat or dull areas are an indication that these areas are not sealed and will require additional thin applications.

4. PREPARING VOID AREAS:

A.Heavy polypropylene tape such as Tuck tape can be used to seal off cracks or small voids.Cured epoxy will not stick to it Apply to back of slabs, press firmly to remove trapped air pockets between tape and wood surface.

B.CONTAINMENT BOX: Large tops with voids may require additional steps such as a containment box made from products such as white melamine particleboard or similar material. Depending on the type of material used, a mold release, paste wax such as Trewax or heavy polypropylene tape such as Tuck tape must be applied to the melamine particleboard to prevent the resin from adhering to it. We recommend you test the mold release, paste wax or tape prior to fling voids with resin. In addition, we recommend you clamp slab pieces in place preventing them from shifting while fling areas in containment box.

C.CONTAINMENT PANEL: Per the illustration on the following page, use melamine particleboard or similar material to contain resin. Depending on the type of material used, a mold release, paste wax such as Trewax or heavy polypropylene tape such as Tuck tape must be applied to the melamine surface to prevent the resin from adhering to it. We recommend you test the mold release, paste wax or tape prior to fling void with resin. Once this is done, flip the slabs over face side down on level work surface and arrange. Apply a bead of silicone sealant along inside edges. Press the particleboard down tight against the silicone sealant and secure with screws every 4 to 6 inches. Once the slab pieces are secured, flip the melamine particleboard/slab unit over, face side up. Tape or seal exposed ends, joints and seams to prevent leakage.

5.MEASURING VOIDS: These irregular shaped ares can be difficult to measure accurately. One method is to fill small voids with dried rice,then measure the rice used in a measuring container.Another method is measure the length ,width and depth of the void(appro ximate area).Example -72" length x 8" width x 1.5" depth=864 sq inches. Divide this number by 231 to convert the area to gallons.For example 864 sq inches/231=3.74 gallons.

6.Protect work surface and area with plastic drop sheet.

7.Place slab/panel on level work surface, elevate if necessary and level. Depending on your project piece, you may require clamps to hold pieces securely while fling voids with resin.

8.Clean the wood surface with a lint free cotton cloth moistened lightly with isopropyl alcohol.Th is will help to remove all fine dust and containment.

Hot Searches