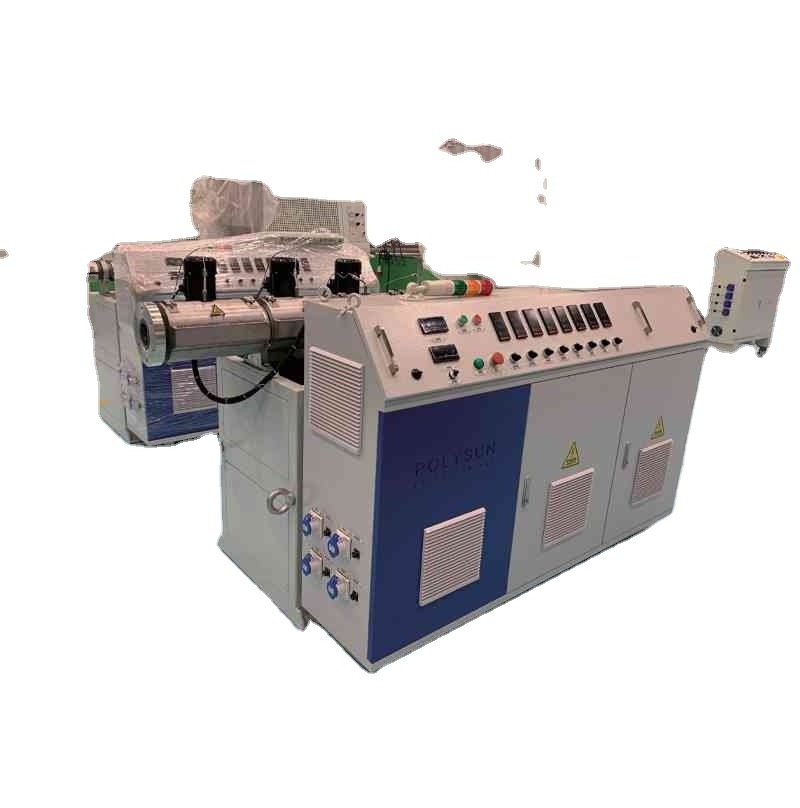

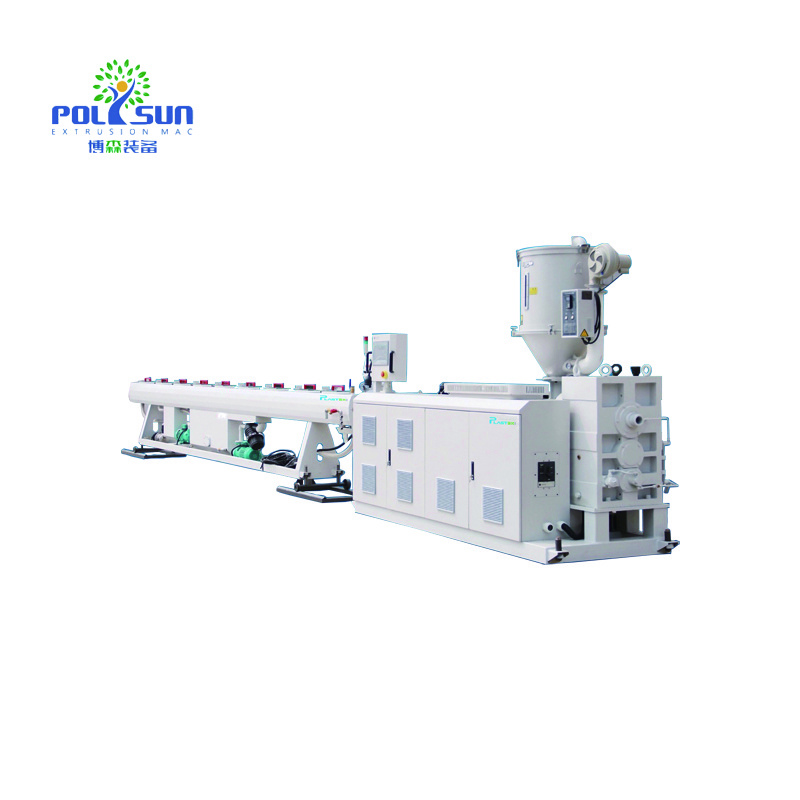

We have the single screw extruder and the double screw extruder. Customers can choose each one according to their requirements for

the output

the output

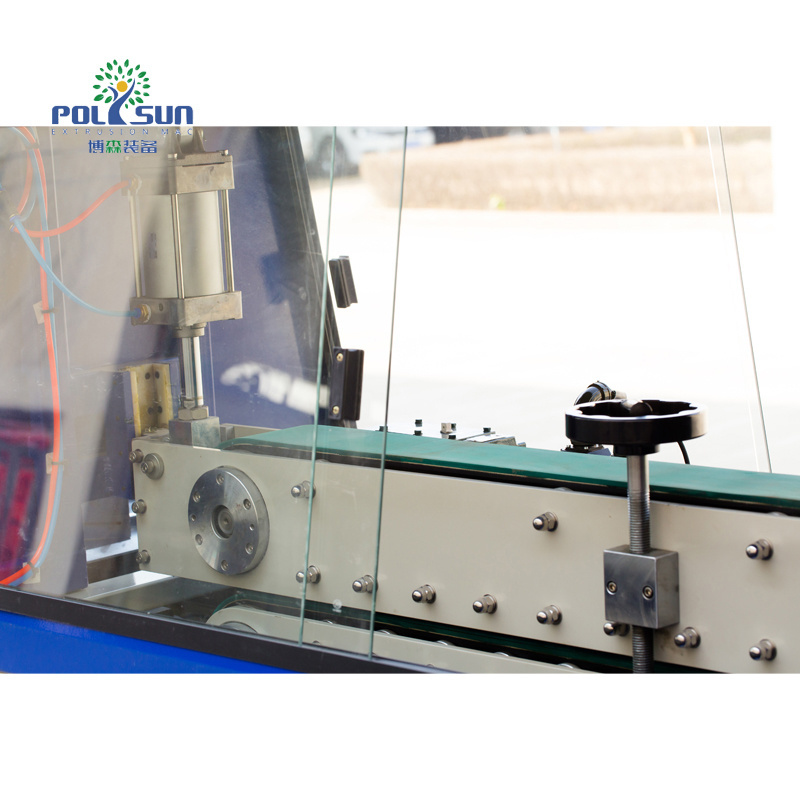

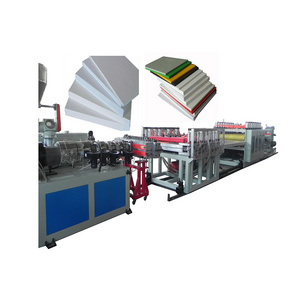

Calibration Table

Smart operating method with two control options. One is the panel with touch screen. Another one is the hung-up type.

Stainless steel frame or steel with powder coating frame using for calibration table to extend the working life.

Smart operating method with two control options. One is the panel with touch screen. Another one is the hung-up type.

Stainless steel frame or steel with powder coating frame using for calibration table to extend the working life.

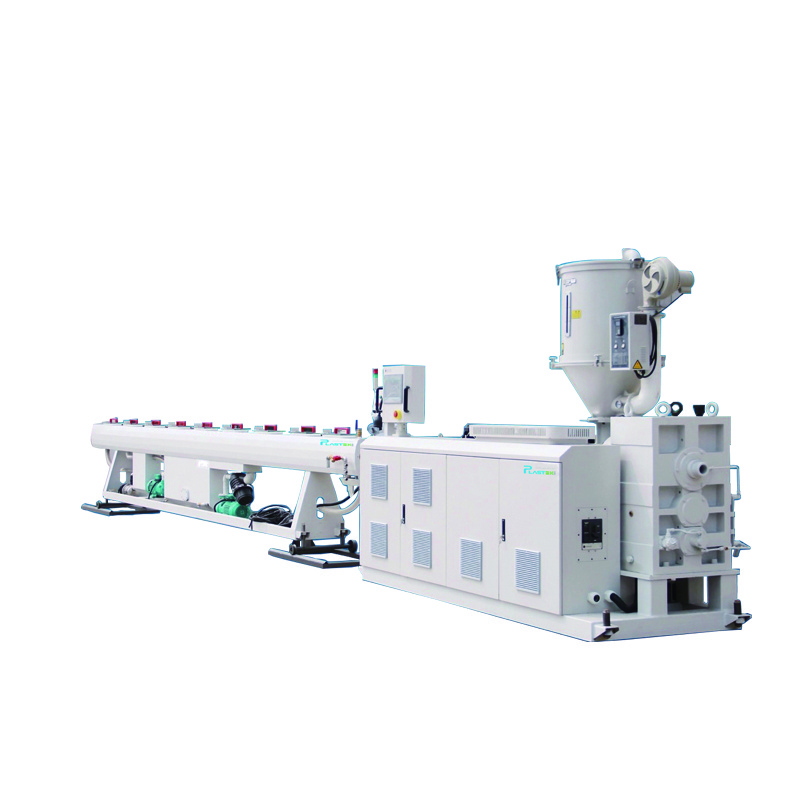

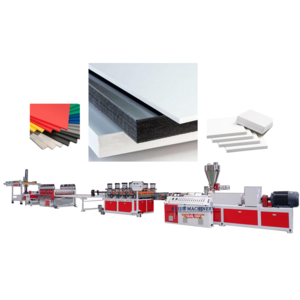

Haul-off and cutting machine

caterpillar and belt for haul-off machine options.

saw blade and guillotine for cutting machine options

caterpillar and belt for haul-off machine options.

saw blade and guillotine for cutting machine options