- Product Details

- {{item.text}}

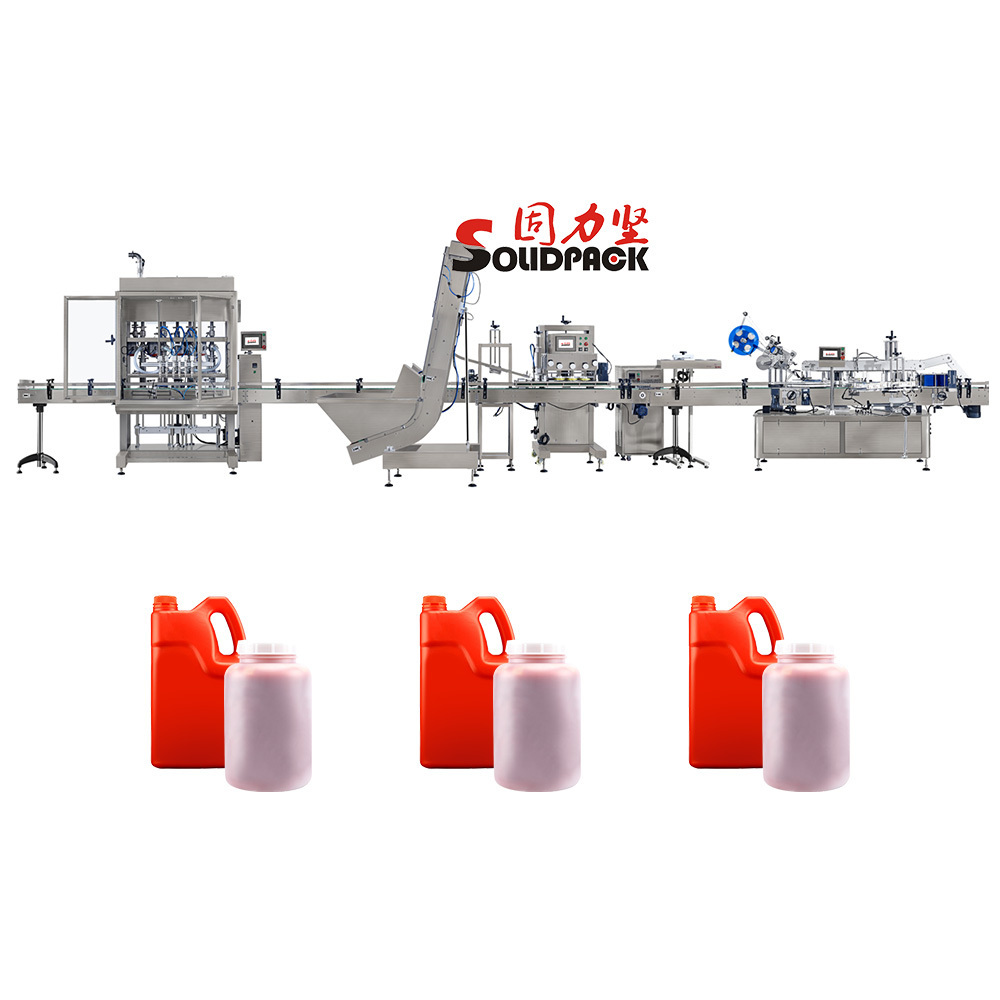

Quick Details

-

Filling Accuracy:

-

±0.5-1%

-

Packaging Type:

-

Strong Wooden Case

-

Voltage:

-

220V/380V 50/60Hz

-

Place of Origin:

-

Tianjin, China

-

Brand Name:

-

Solidpack

-

Dimension(L*W*H):

-

2000*900*2200mm (L*W*H)

-

Weight:

-

450 KG

-

Product name:

-

Piston Filling Machine

-

Material:

-

Stainless Steel 304/316

-

Usage:

-

Filling Capping Labeling Packaging

-

Keywords:

-

Fillng Machine

-

Suitable for:

-

High Viscous Products

-

Control:

-

PLC+ Touch Screen

-

Feature:

-

High Precision Filling Level

-

After Warranty Service:

-

Video technical support Online support

-

After-sales Service Provided:

-

Video technical support Online support

-

Certification:

-

CE

Quick Details

-

Machinery Capacity:

-

2000BPH, Other

-

Packaging Material:

-

Wood

-

Filling Material:

-

Oil, Other

-

Filling Accuracy:

-

±0.5-1%

-

Packaging Type:

-

Strong Wooden Case

-

Voltage:

-

220V/380V 50/60Hz

-

Place of Origin:

-

Tianjin, China

-

Brand Name:

-

Solidpack

-

Dimension(L*W*H):

-

2000*900*2200mm (L*W*H)

-

Weight:

-

450 KG

-

Product name:

-

Piston Filling Machine

-

Material:

-

Stainless Steel 304/316

-

Usage:

-

Filling Capping Labeling Packaging

-

Keywords:

-

Fillng Machine

-

Suitable for:

-

High Viscous Products

-

Control:

-

PLC+ Touch Screen

-

Feature:

-

High Precision Filling Level

-

After Warranty Service:

-

Video technical support Online support

-

After-sales Service Provided:

-

Video technical support Online support

-

Certification:

-

CE

Our Advantages

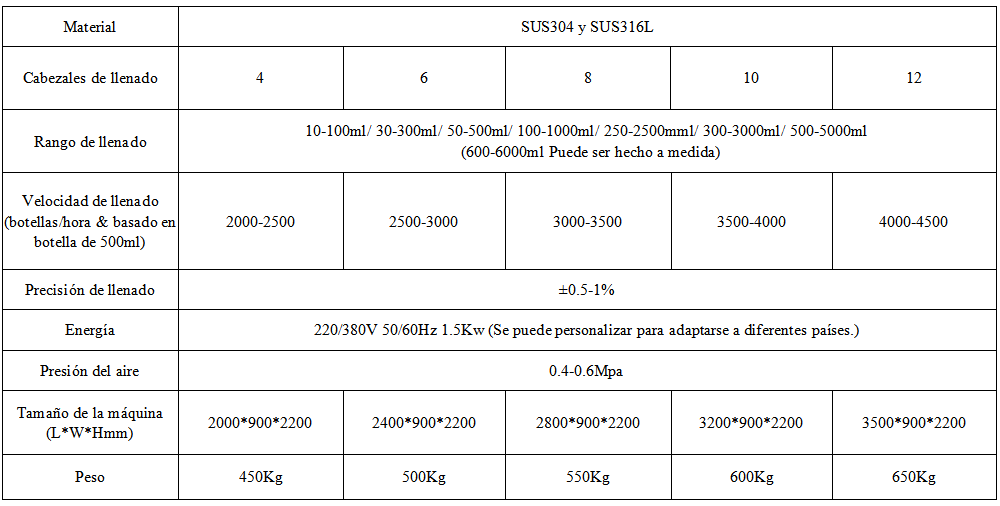

Specification

|

Material

|

SUS304 and SUS316L

|

|

|

|

|

||||

|

Filling heads

|

4

|

6

|

8

|

10

|

12

|

||||

|

Filling range

|

10-100ml/ 30-300ml/ 50-500ml/ 100-1000ml/ 250-2500mml/ 300-3000ml/ 500-5000ml

(600-6000ml can be tailor made)

|

|

|

|

|

||||

|

Filling speed

(bottles/ hour & based on 500ml bottle)

|

2000-2500

|

2500-3000

|

3000-3500

|

3500-4000

|

4000-4500

|

||||

|

Filling precision

|

±0.5-1%

|

|

|

|

|

||||

|

Power

|

220/380V 50/60Hz 1.5Kw (Can be tailor made to suit different countries)

|

|

|

|

|

||||

|

Air pressure

|

0.4-0.6Mpa

|

|

|

|

|

||||

|

Machine size

(L*W*Hmm)

|

2000*900*2200

|

2400*900*2200

|

2800*900*2200

|

3200*900*2200

|

3500*900*2200

|

||||

|

Weight

|

450Kg

|

500Kg

|

550Kg

|

600Kg

|

650Kg

|

||||

maquina de llenado neumatica 100ml

Product Description

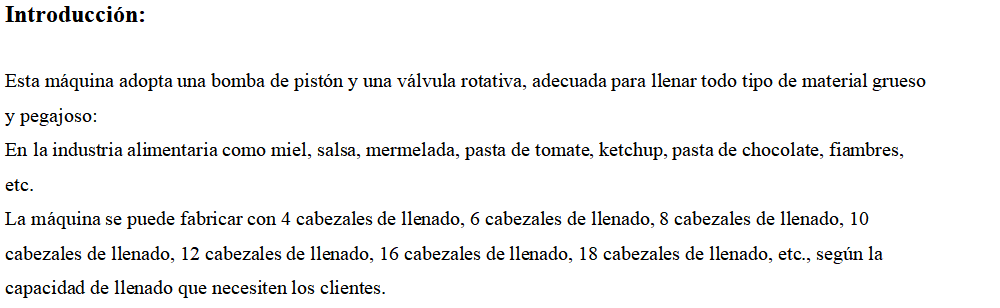

Introduction:

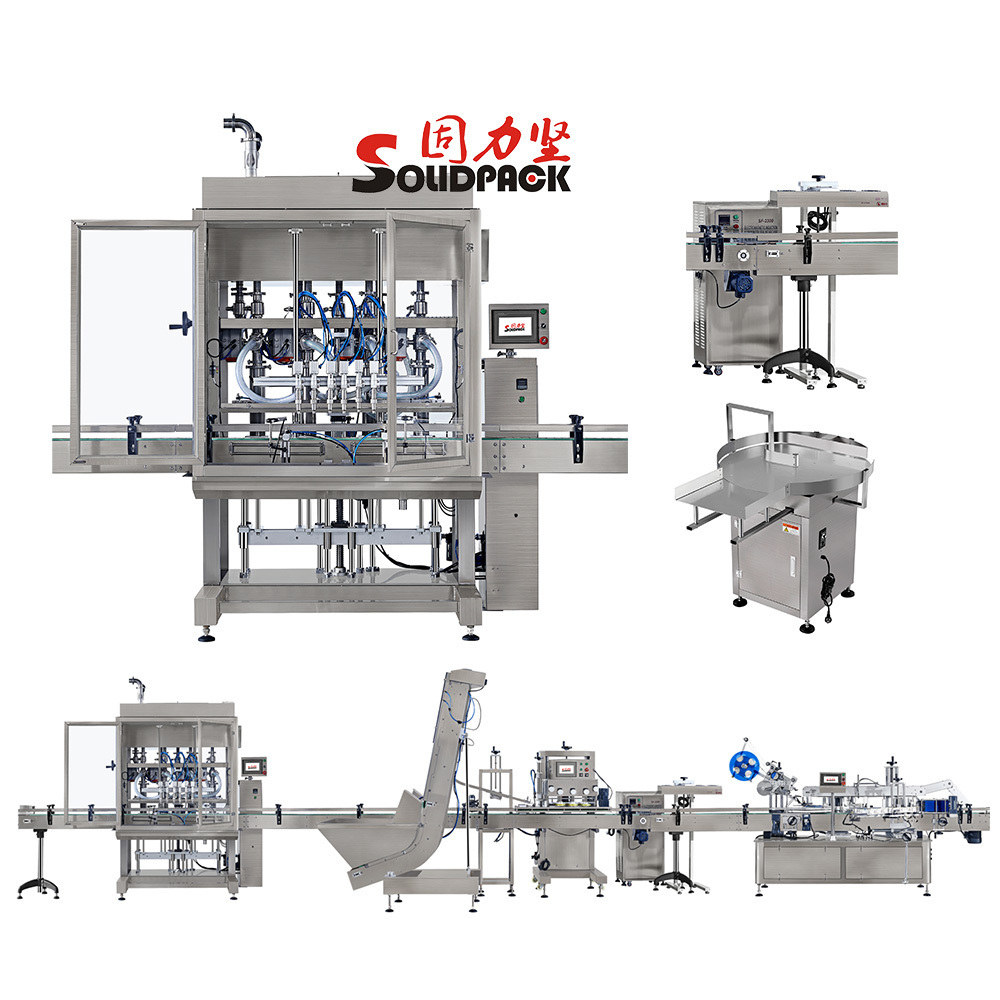

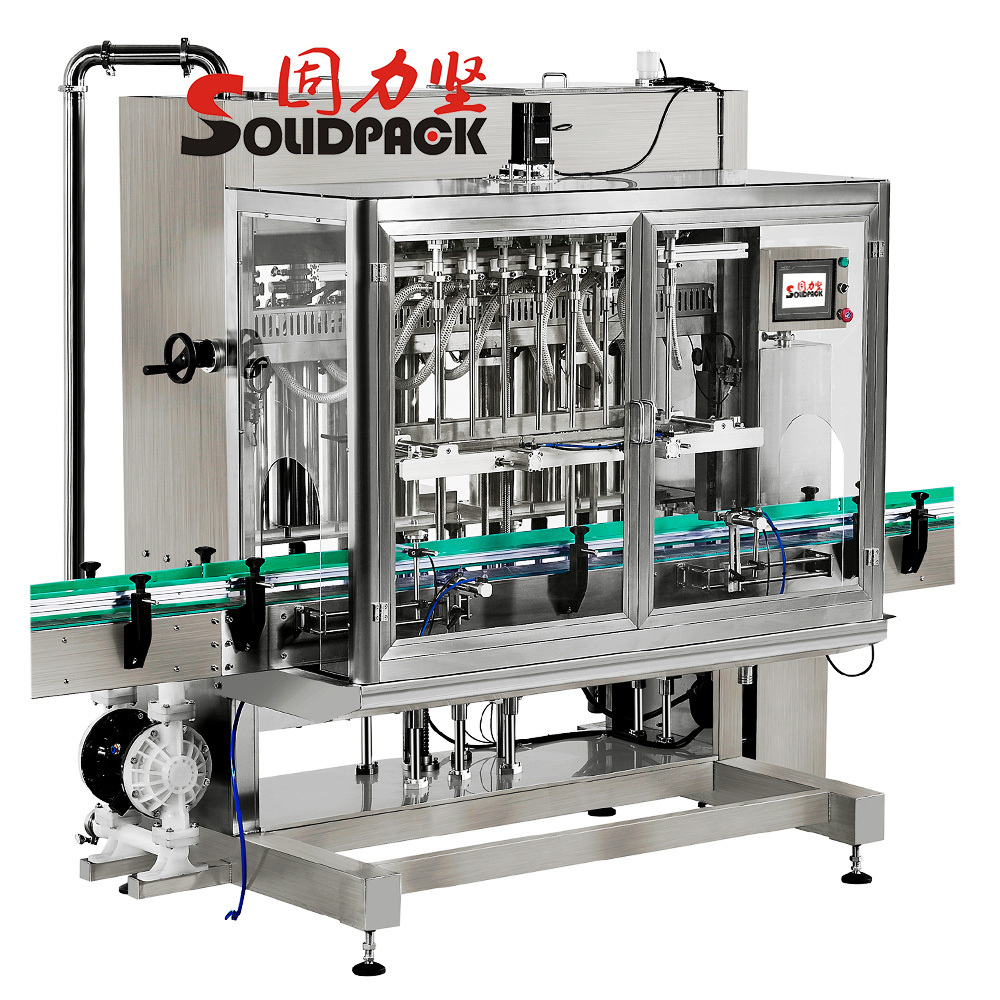

In food industry like, tomato paste, chilli sauce, honey, butter, ketchup lunch meat, mayonnaise, marmadele, etc. The machine can be made with 4 filling heads/ 6 filling heads/ 8 filling heads/ 10 filling heads/ 12filling heads ,16 filling heads, 18 filling heads etc, according to the filling capacity customers needed.

maquina de llenado neumatica 100ml

maquina de llenado neumatica 100ml

maquina de llenado neumatica 100ml

Features:

The machine adopts full-auto PLC + human-computer touch screen control system. For different grams for example, 100ml, 500ml, 1000ml, we set three procedures, mode 1, mode 2, model 3. The PLC can save these parameters for later use. Operators do not need too much complicated adjustments; the filling machine can switch between the three models easily.

Machine parts use stainless steel SUS304 & SUS316L. The machine use world word-class brand components, such as photo sensor---Keyence (Japan) PLC---Mitsubishi (Japan) Electrinic control part---Schneider (France) Touch screen---Delta (Taiwan) Or MCGS(Beijing China) Cylinder--AirAc (Taiwan). There is a sensor on tank to start or stop the pump transfer liquid/ paste or stop transfer. It is automatically. For hot filling, we make double tank, which can be heated to keep temperature for material inside. Also with a mixer inside to stir material even, ensure good filling accuracy.

To ensure the bottles and filling heads are in the correct position, we add a special bottles position device to make the whole

filling process smooth and stable. No bottle no filling.

The filling heads are specially made, with the function of anti-drop and anti-drawing & bubble-kill. Can make diving filling heads

to move together with liquid level.

Transaction process

Hot Searches