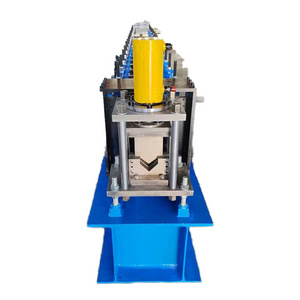

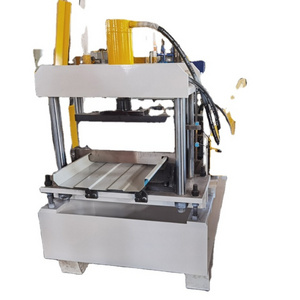

The cutting device is driven by hdyraulic station.

Meterial of the cutting:Cr12Mov with quenched treatment.

It can decide cut panel dimension acoording to the hydraulic drive and Plc computer control system.

- Product Details

- {{item.text}}

Quick Details

-

Rolling thinckness:

-

0.3-0.7mm

-

Place of Origin:

-

Hebei, China

-

Brand Name:

-

Rfm

-

Voltage:

-

380V 50Hz 3Phases

-

Dimension(L*W*H):

-

5000*800*1200Mm

-

Weight:

-

3500 kg

-

Feeding width:

-

Customer request

-

Marketing Type:

-

New Product 2021

-

After-sales Service Provided:

-

Engineers available to service machinery overseas

-

raw material:

-

PPGI GI PPGL GL

-

feeding width:

-

as customers requirement

-

warranty:

-

2 years

-

motor brand:

-

china famous brand

-

name:

-

low price gutter making machine

-

plc:

-

mitsubishi/delixi/siemens

-

profiles:

-

as customers requirement

-

Roller material:

-

High Grade 45# Steel Quenched

-

cutting blade material:

-

cr12 with quenched treatment

Quick Details

-

Type:

-

Tile Forming Machine

-

Tile Type:

-

Steel

-

Production Capacity:

-

30 m/min

-

Rolling thinckness:

-

0.3-0.7mm

-

Place of Origin:

-

Hebei, China

-

Brand Name:

-

Rfm

-

Voltage:

-

380V 50Hz 3Phases

-

Dimension(L*W*H):

-

5000*800*1200Mm

-

Weight:

-

3500 kg

-

Feeding width:

-

Customer request

-

Marketing Type:

-

New Product 2021

-

After-sales Service Provided:

-

Engineers available to service machinery overseas

-

raw material:

-

PPGI GI PPGL GL

-

feeding width:

-

as customers requirement

-

warranty:

-

2 years

-

motor brand:

-

china famous brand

-

name:

-

low price gutter making machine

-

plc:

-

mitsubishi/delixi/siemens

-

profiles:

-

as customers requirement

-

Roller material:

-

High Grade 45# Steel Quenched

-

cutting blade material:

-

cr12 with quenched treatment

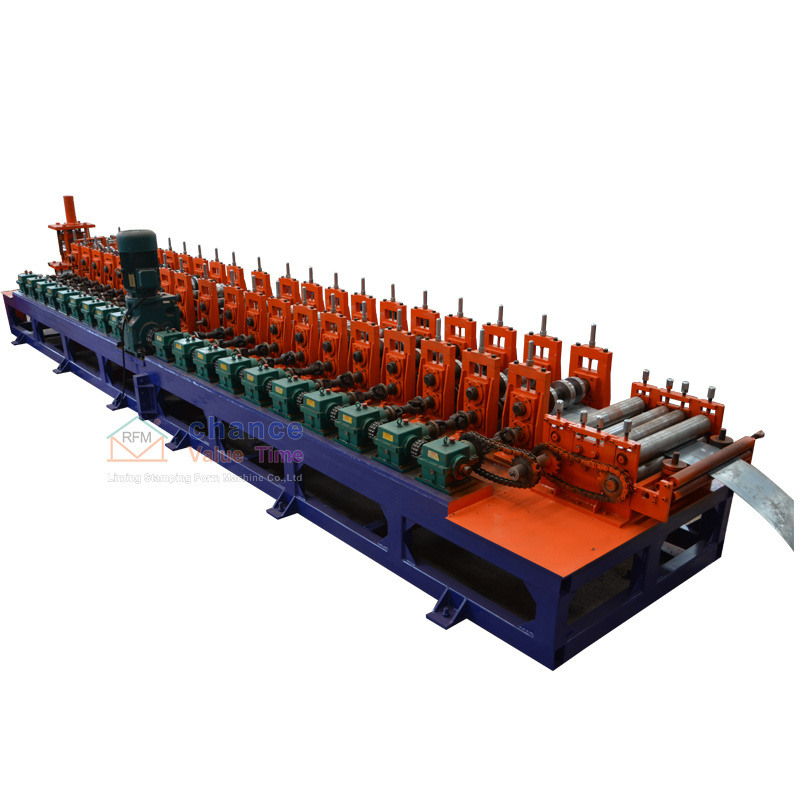

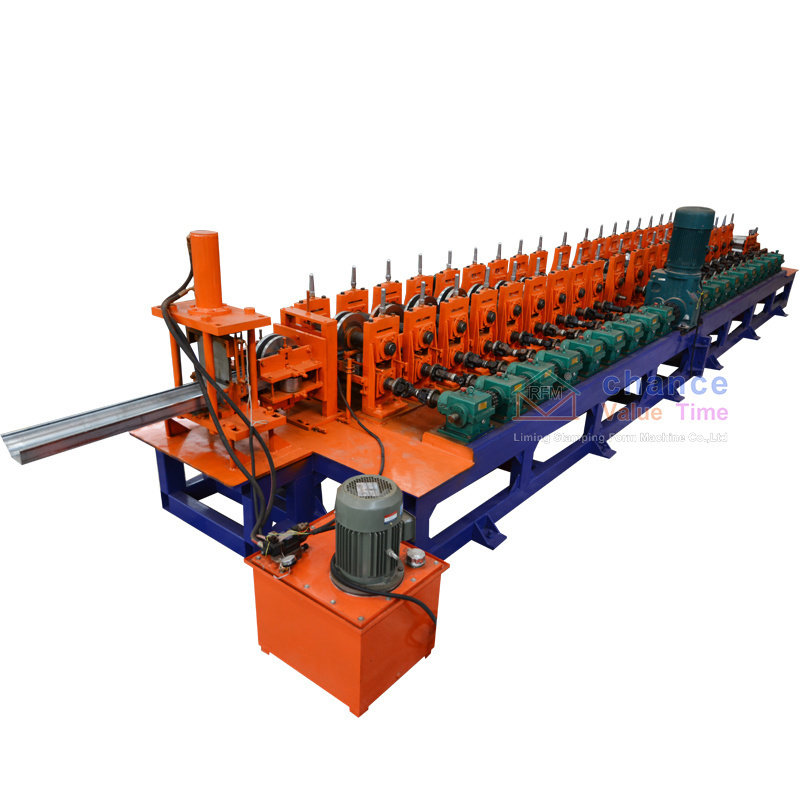

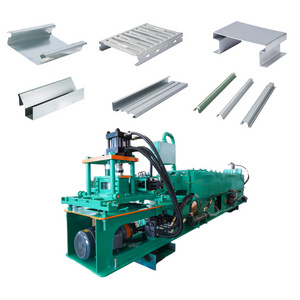

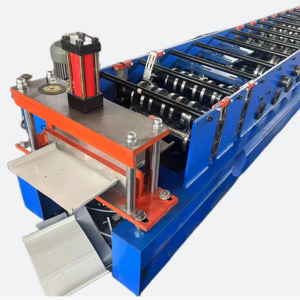

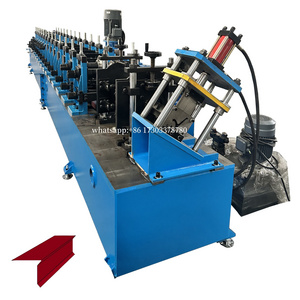

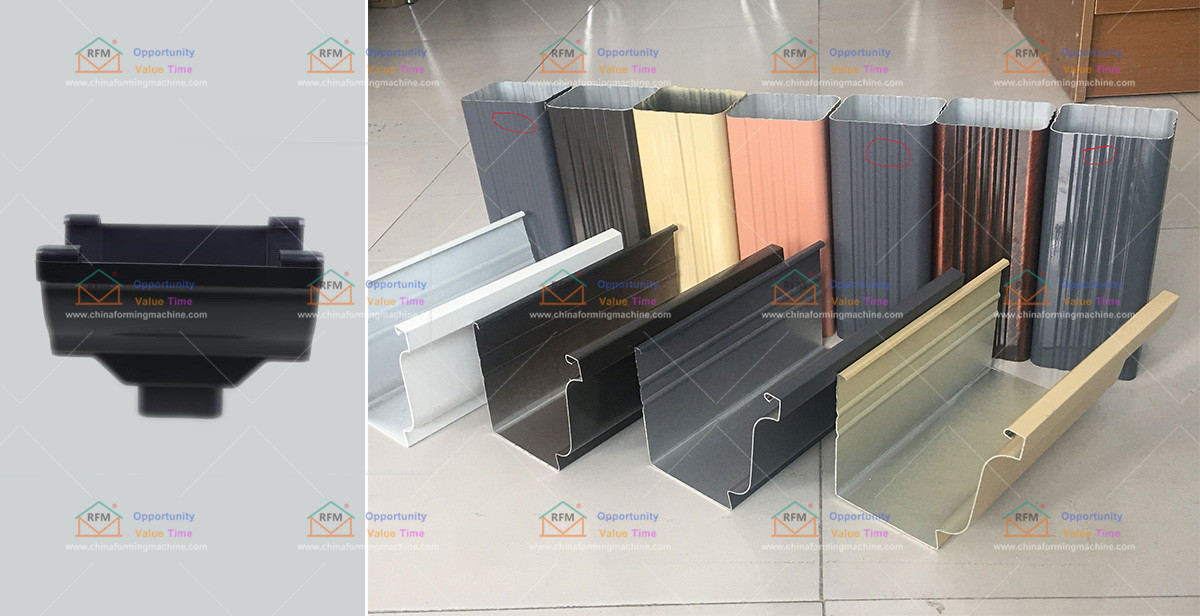

Low price gutter making machine automatic customized style gutter roll forming machine

|

name

|

gutter making machine

|

|

After-sales Service Provided

|

Engineers available to service machinery overseas

|

|

raw material

|

PPGI GI

|

|

operate style

|

automatic

|

|

thickness

|

0.3-0.7mm

|

|

warranty

|

2 years

|

|

plc

|

mitsubishi/delixi/siemens

|

|

cutting blade material

|

cr12 with quenched treatment

|

We can provide solutions to solve the problem of slow drainage ditch production in factories in the construction industry and manufacturing industry that affects production efficiency.

Click the image below to start online customization for the design you want.

We provide a gutter press with hydraulic motor to meet the customer's requirements for the production speed of the gutter production line and solve the customer's low production efficiency. Our company's arc roof tile pressing equipment is equipped with a hydraulic motor, which makes its production efficiency twice that of ordinary machines. This hydraulic motor is a German Siemens brand. The other parts of the machine are well-known brands at home and abroad. The brand can provide us with good quality parts, and good quality parts can assemble good quality machines. In addition, the working speed of the machine is carefully designed by our professional design team, which ensures the speed of the machine and the stability of the machine.

Rollers material

The rollers material is h

igh Grade 45# Steel Quenched

.The hardness is around HRC 58-62℃.

This structure uses double bearing,can make the production process much mor smoothly,less noisy,longer sevice life.

Uncoiling→ Feeding material into machine →Roll forming → Auto cutting →Products receiving

As the original manufacturer of the tile press, we can produce most of the products according to your requirements, not just the size of the products on this page

Liming Stamping Form Machine Co.,Ltd. occupies an area of 156,000 square meters and 6 large production plants. It has been established in 1996 with many years of production experience, serving 156 countries, 4 international machinery patents, 10 Chinese machinery patents, nationally certified high-tech company.China's top three steel-building materials equipment factories.

Products mainly include

trapezoidal steel roof/wall panel machine, C&Z shape purline machine, high-way guardrail machine, sandwich panel production line, deck forming machine, C U L light keel machine, shutter slat door forming machine, cutting machine, downpipe machine, gutter machine

, etc.

In the subsequent quality inspection, we provide professional instruments to test and adjust, detect the pressure of the tubing, and the wheels. Hardness and precision. We ensure the quality of the product itself through a series of tests and bring you a better product experience.

Warranty:

Two years, and we will provide technical support for wholelife of the equipment.

If some parts of machine broken within 2 year, we will give customer the spare parts for free. (include chain, bearing, roller,oil pipe, counting wheel) If more than 2 year, maybe some spare parts need to be charged. If machine can not work well, we can teach them online until the machine is perfect. If you need, we can go to your place to assist you. But you need to provide the cost of the engineer.

Packing Method:

Main machine is packaged with plastic film

Transportation:

All machines need one 40 feet container to hold

P

ayment Term :

30% deposit by T/T in advance and 70% balance after inspection confirmation before shipment.

Delivery Time

:

Within 35 days after receiving deposit.

Hot Products

Q: Can you customize the machine from your company?

A: Of course, we can manufacture the machine according to your customized size demand.

Q: How is the quality? Is there any department related to quality control?

A: All raw materials we use are quality controlled. Workers will take care of every detail when handling production and packaging. The quality control department is responsible for the quality of each process.

Q: Is the packaging form?

A: Yes, of course! All our machines will be packaged in dust and water proof, and they can be reinforced after loading to fully meet export packaging standards.

Q: How about after-sales service?

A: TM is online 24 hours a day, and you can also contact them via email, Skype, MSN, whatsapp. and many more Two-year warranty and parts replacement.

Hot Searches