- Product Details

- {{item.text}}

Quick Details

-

MF:

-

(C2H6OSi)n.C3H9Si

-

EINECS No.:

-

000000

-

Place of Origin:

-

Hubei, China

-

Type:

-

Defoamer

-

Brand Name:

-

Si Hai

-

Model Number:

-

SH-Y106

-

Appearance:

-

Light yellow to yellow oily liquid

-

PH value:

-

5.0-8.0

-

Viscosity(25℃):

-

50-1000mPa.s

-

Dispersity:

-

Suspended and dispersed in water

-

Specific Gravity(g/ml):

-

0.8-1.0

-

Key word:

-

Defoamer for for Water-Based Paint and Printing Ink

-

Function:

-

defoamer chemical

-

Raw material:

-

defoamer emulsion

-

Free samples:

-

500g

Quick Details

-

CAS No.:

-

9006-65-9

-

Purity:

-

100%

-

Other Names:

-

Polydimethylsiloxane emulsion

-

MF:

-

(C2H6OSi)n.C3H9Si

-

EINECS No.:

-

000000

-

Place of Origin:

-

Hubei, China

-

Type:

-

Defoamer

-

Brand Name:

-

Si Hai

-

Model Number:

-

SH-Y106

-

Appearance:

-

Light yellow to yellow oily liquid

-

PH value:

-

5.0-8.0

-

Viscosity(25℃):

-

50-1000mPa.s

-

Dispersity:

-

Suspended and dispersed in water

-

Specific Gravity(g/ml):

-

0.8-1.0

-

Key word:

-

Defoamer for for Water-Based Paint and Printing Ink

-

Function:

-

defoamer chemical

-

Raw material:

-

defoamer emulsion

-

Free samples:

-

500g

Product Description

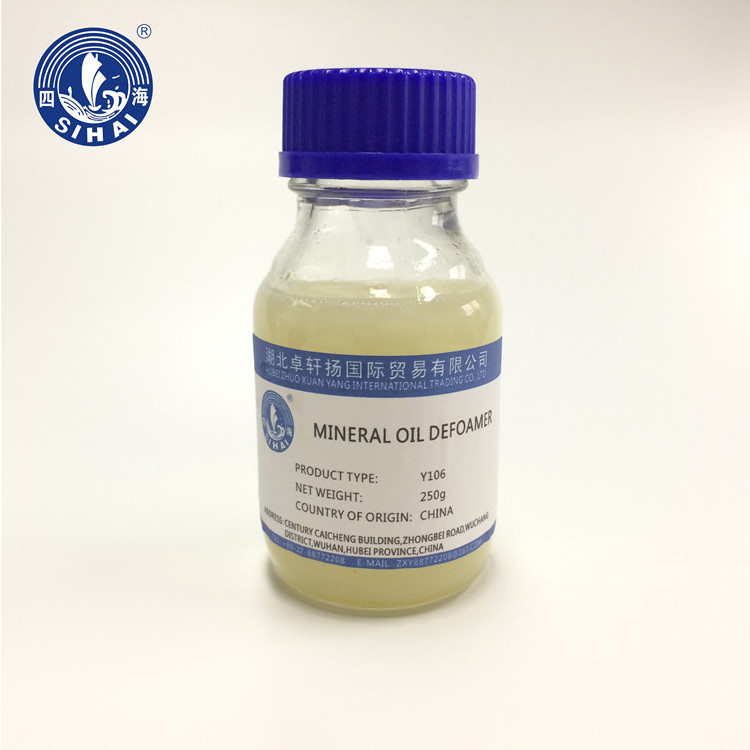

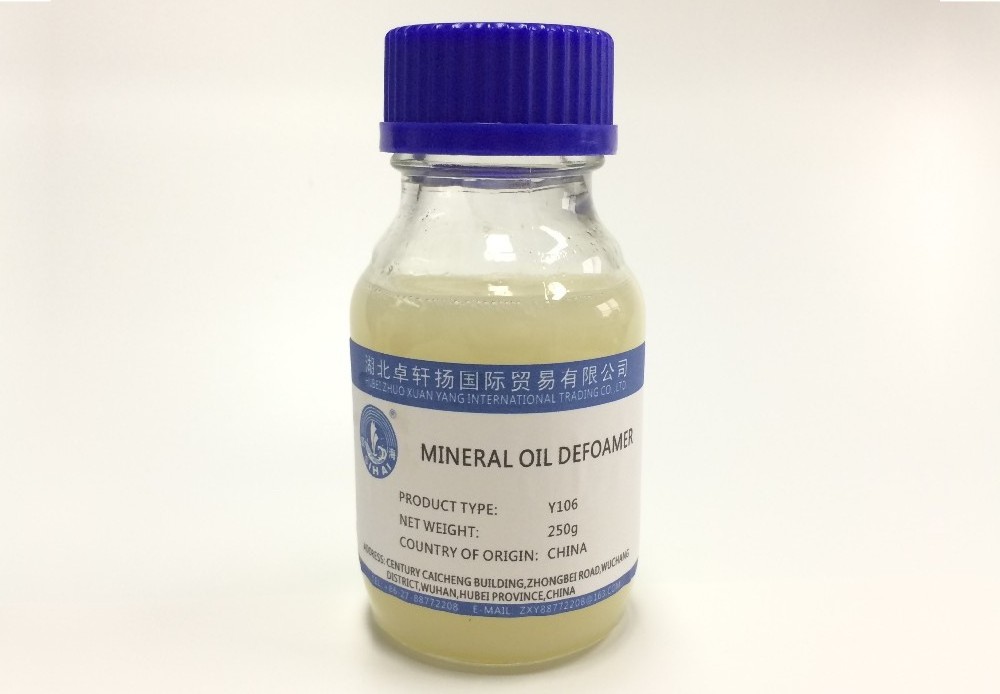

Mineral Oil-based Defoamer Chemical and Anti foams SH-Y106 for Water-Based Paint and Printing Ink

Main composition:

mineral oil, fatty acid metal soap and dispersant

Advantage:

has little effect on the coating/painting film and with high efficiency

Particularly suitable for aqueous ink systems

Specification

|

Item

|

Index

|

|

|

Appearance

|

Light yellow to yellow oily liquid

|

|

|

PH value

|

5.0-8.0

|

|

|

Viscosity(25℃)

|

50-1000mPa.s

|

|

|

Dispersity

|

Suspended and dispersed in water

|

|

|

Specific Gravity(g/ml)

|

0.8-1.0

|

|

|

Note: The above data is for reference only and is not intended as a technical indicator

|

|

|

Application

This Mineral Oil-based Defoamer Chemical is mainly used for :

Water-Based Paint and Ink

l Water-based architectural coatings for high, medium and low PVC;

l Other polymer systems that cannot use silicone;

l Water-based architectural coatings for high, medium and low PVC;

l Other polymer systems that cannot use silicone;

How to use

1.

SH-Y106 foam control agent is composed of a variety of substances, which may be stratified or precipitated during storage, which is normal. It is recommended that the user stir slightly before use, without affecting the use effect.

2.

SH-Y106 antifoams can not be diluted with water, but can be added directly to the foaming system. If diluted with water,

stratification may occur, which will reduce the effect of defoaming and will eventually lead to an increase in the cost of use.

stratification may occur, which will reduce the effect of defoaming and will eventually lead to an increase in the cost of use.

3.

Because SH-Y106 defoamer has strong antifoaming properties, it can be added to the product as a foam suppressing component. The recommended addition amount is 0.1~0.5% of the total formula amount. It can also be added in stages. Add 40% of the mass in the grinding stage, and add the remaining 60% in the paint adjustment stage (before adding the emulsion). The optimum amount is determined by the user through field trials.

Packing & Delivery

1.

This antifoams agent for paint and ink is packed in 25kg/50kg/200kg PE drums, or customized according to customer requirements.

2. Store at 5-35 °C to avoid direct heating. If it is burning on fire, extinguish the fire according to the general petroleum

product method.

2. Store at 5-35 °C to avoid direct heating. If it is burning on fire, extinguish the fire according to the general petroleum

product method.

3.

At the temperature of 10~30 °C, the shelf life is 6 months from the date of production without opening the package.

Hot Searches