- Product Details

- {{item.text}}

Quick Details

-

Warranty of core components:

-

1years

-

Brand Name:

-

Manvac, Manvac

-

Voltage:

-

220V/50Hz/3Phase as usual

-

Dimension(L*W*H):

-

420*340*570

-

Weight (KG):

-

13.5 KG

-

Power (kW):

-

1

-

Material:

-

304 Stainless Steel

-

Certification:

-

CE

-

Voltage specifications:

-

3ph 220V 50Hz

-

Feeding height:

-

3.5m

Quick Details

-

Capacity (kg/h):

-

300 kg/h

-

Place of Origin:

-

Guangdong, China, Guangdong,China

-

Application:

-

Plastic Loader, injection molding machine, Plastic industry

-

Warranty of core components:

-

1years

-

Brand Name:

-

Manvac, Manvac

-

Voltage:

-

220V/50Hz/3Phase as usual

-

Dimension(L*W*H):

-

420*340*570

-

Weight (KG):

-

13.5 KG

-

Power (kW):

-

1

-

Material:

-

304 Stainless Steel

-

Certification:

-

CE

-

Voltage specifications:

-

3ph 220V 50Hz

-

Feeding height:

-

3.5m

Factory Price High Power Recycling Hopper Plastic Loader Suction Machine Automatic Dust Removal Vacuum Plastic

Manvac A pair or tow/four separation type automatic material feeding machine series,suitable for the transport of plastic particles,the main use of motor operation to produce a vacuum,so that the material can produce a pressure difference to transport the plastic.

Product Description

Stainless steel hopper, to ensure that the raw material is not contaminated. Microcomputer control, simple operation, precise control, and there are a number of alarm indicator.

Motor protection device, can increase its service life.

Lack of alarm, can take the initiative to inform customers of the situation.

Independent filter device to facilitate the removal of dust; filter view window, to facilitate customers to view the use of filter, and regular cleaning.

Vacuum hopper (JMH) can be directly installed in the molding machine hopper; electric eye hopper (JVH) can be directly installed in the molding machine feeding port. Optional cyclone dust collector, reducing filter cleaning times, suitable for crushing and conveying.

Optional JPV-U Europeanization of material two proportional valve (including purchase control box), for new material and powder mixture use or crushed material immediate recovery.

When transporting raw materials, crushing material accounted for more than 30%, the proposed selection of14 mesh stainless steel mesh.

|

Model

|

Motor Type

|

Motor Power

(KW)

|

Dimensions

(MM)

|

Net weight

(KG)

|

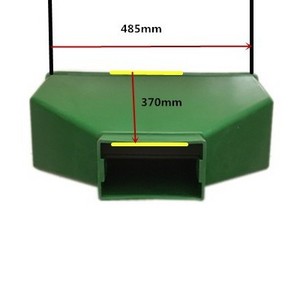

Hopper

(MM)

|

Hopper capacity

(L)

|

Suction Diameter

(MM)

|

Conveying Diameter

(MM)

|

Transmission Capacity

(KG/HR)

|

|

CAL-300G

|

Carbon Brush

|

1.1

|

420*340*570

|

13.5

|

420*350*270

|

7.5

|

38

|

38

|

300

|

|

CAL-700G

|

Carbon Brush

|

1.1

|

530*295*360

|

18

|

420*350*270

|

6

|

38

|

38

|

300

|

|

CAL-800G

|

|

0.75

|

620*370*410

|

40

|

420*350*270

|

7.5

|

38

|

38

|

300

|

|

CAL-800G2

|

|

1.5

|

620*370*410

|

47

|

480*360*330

|

7.5

|

38

|

38

|

500

|

|

CAL-900G

|

|

0.75

|

600*370*700

|

50

|

420*350*270

|

7.5

|

38

|

38

|

500

|

|

CAL-900G2

|

|

1.5

|

600*370*700

|

57

|

480*360*330

|

1.2

|

38

|

38

|

700

|

CERTIFICATE

SUCCESSFUL PROJECT

Hot Searches