We stocks many different types of foam with the following special properties:

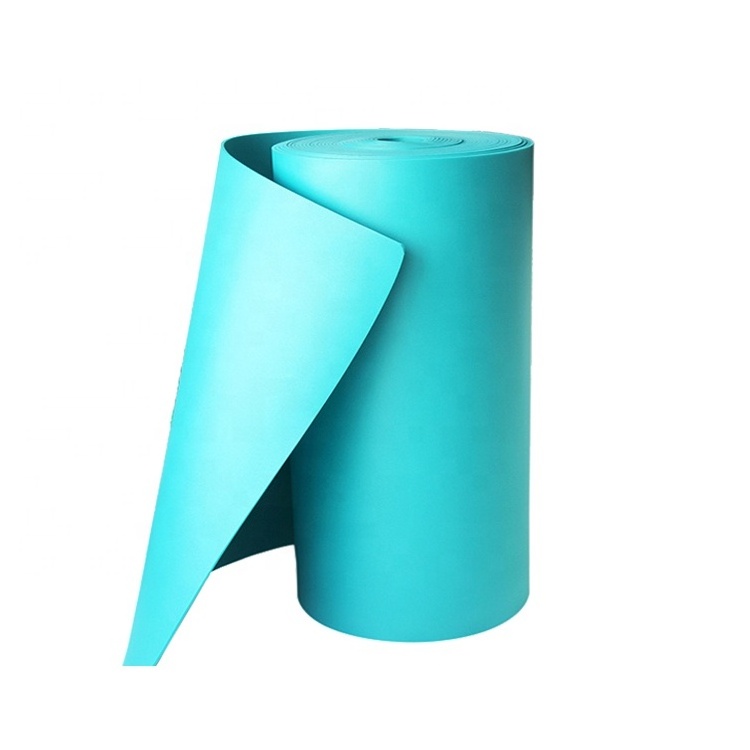

Adhesive PE Foam

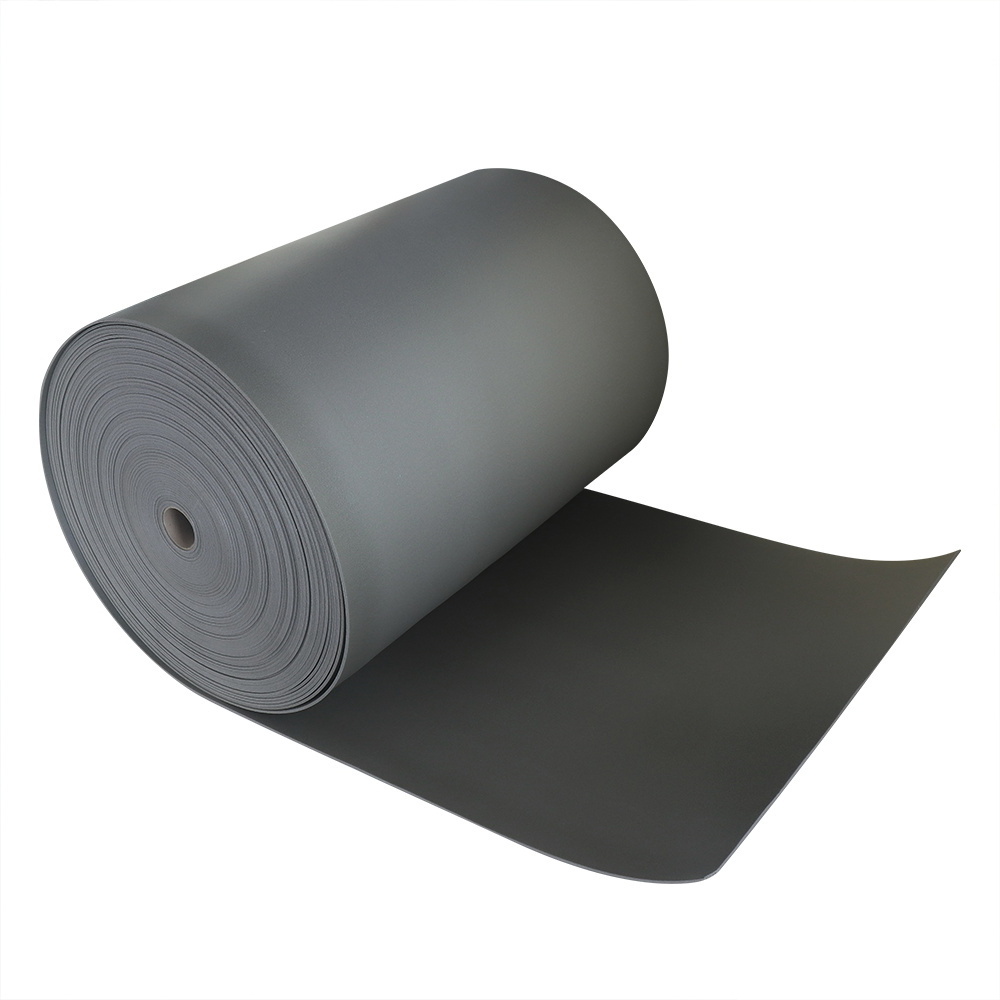

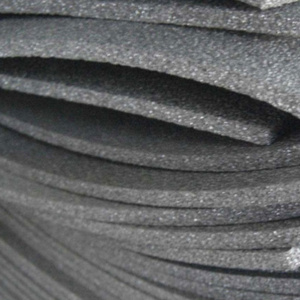

Sound Insulation PE Foam

Heat Insulation PE foam

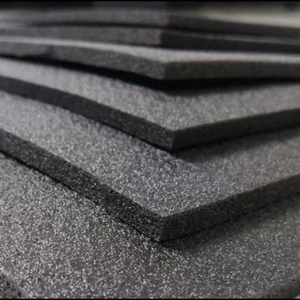

Electrostatic Dissipative (ESD) PE Foam

Fire Retardant (FR) PE Foam

Waterproof PE Foam

Shock absorption Foam

Used in automobile, air conditioning and refrigeration,

construction, sports safety equipment, medical supplies, ESD

packaging for electronic products, etc.