1)

. Electric Circuit printed on tube surface, to heating the water flow inside. Complete isolation and safety.

2)

. Compact size, high heat utilization

3)

. Available Power 3KW

4)

. SUS430 Stainless Steel

- Product Details

- {{item.text}}

Quick Details

-

Place of Origin:

-

Henan, China

-

Brand Name:

-

Gidape

-

Weight:

-

0.3 KG

-

Working Temperature Range:

-

180 - 300 ℃

-

Core Components:

-

Thick film heating plate

-

Feature:

-

replace aluminum cast and immersion heating element

-

Service:

-

Engineers available to service machinery overseas

-

Certificates:

-

CQC, RoHS

-

Service Life:

-

>10,000 hours

-

Water Inlet & Outlet:

-

Diameter 16mm

-

Power:

-

1.5KW

-

After-sales Service Provided:

-

Online support

-

Marketing Type:

-

New Product 2020

Quick Details

-

Type:

-

Water Heater

-

Power Source:

-

Electric

-

Voltage:

-

220V

-

Place of Origin:

-

Henan, China

-

Brand Name:

-

Gidape

-

Weight:

-

0.3 KG

-

Working Temperature Range:

-

180 - 300 ℃

-

Core Components:

-

Thick film heating plate

-

Feature:

-

replace aluminum cast and immersion heating element

-

Service:

-

Engineers available to service machinery overseas

-

Certificates:

-

CQC, RoHS

-

Service Life:

-

>10,000 hours

-

Water Inlet & Outlet:

-

Diameter 16mm

-

Power:

-

1.5KW

-

After-sales Service Provided:

-

Online support

-

Marketing Type:

-

New Product 2020

Product Description

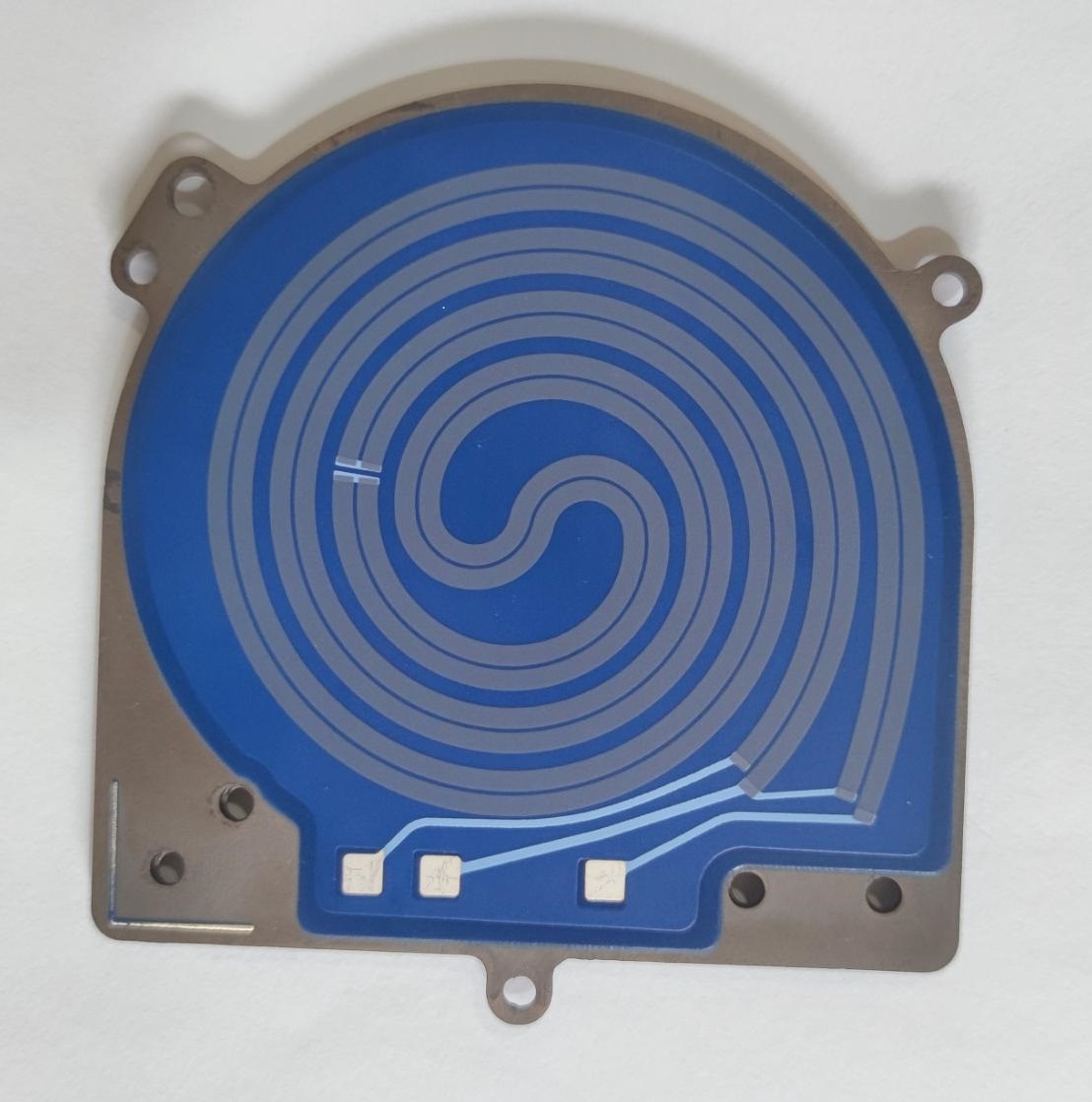

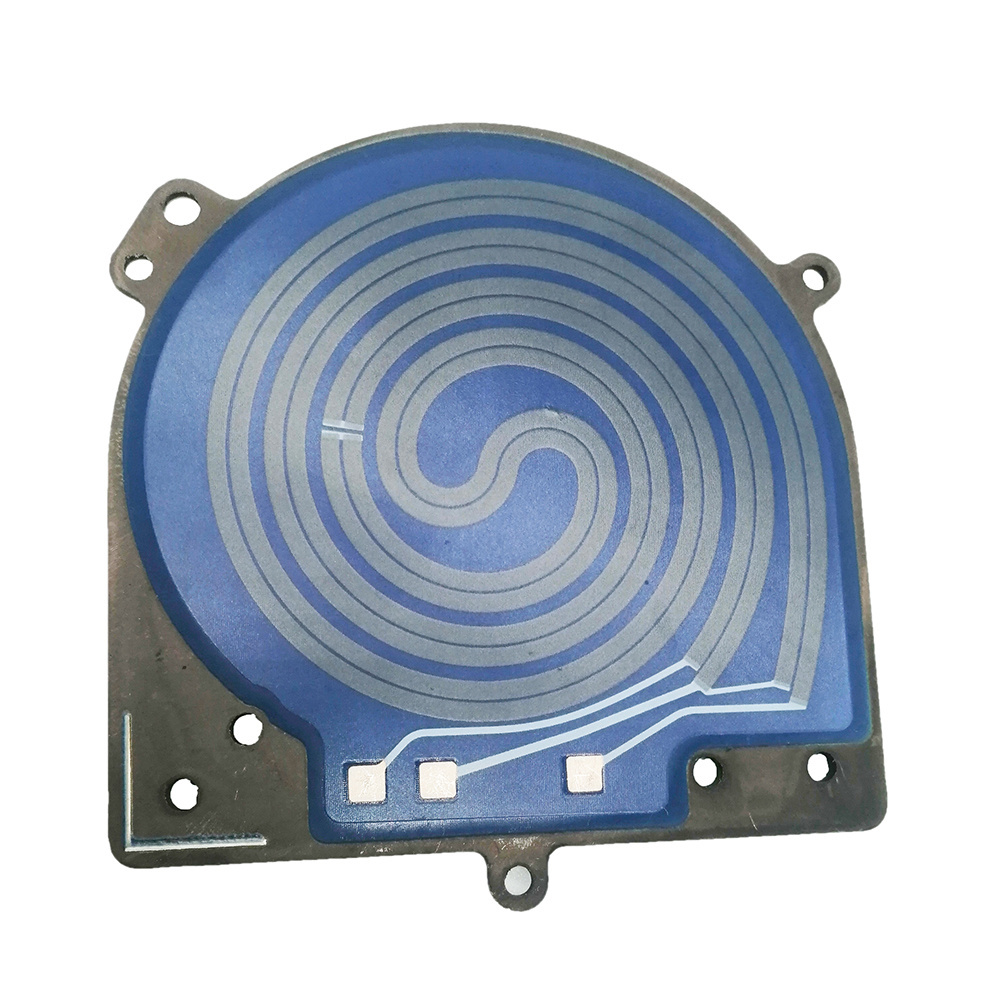

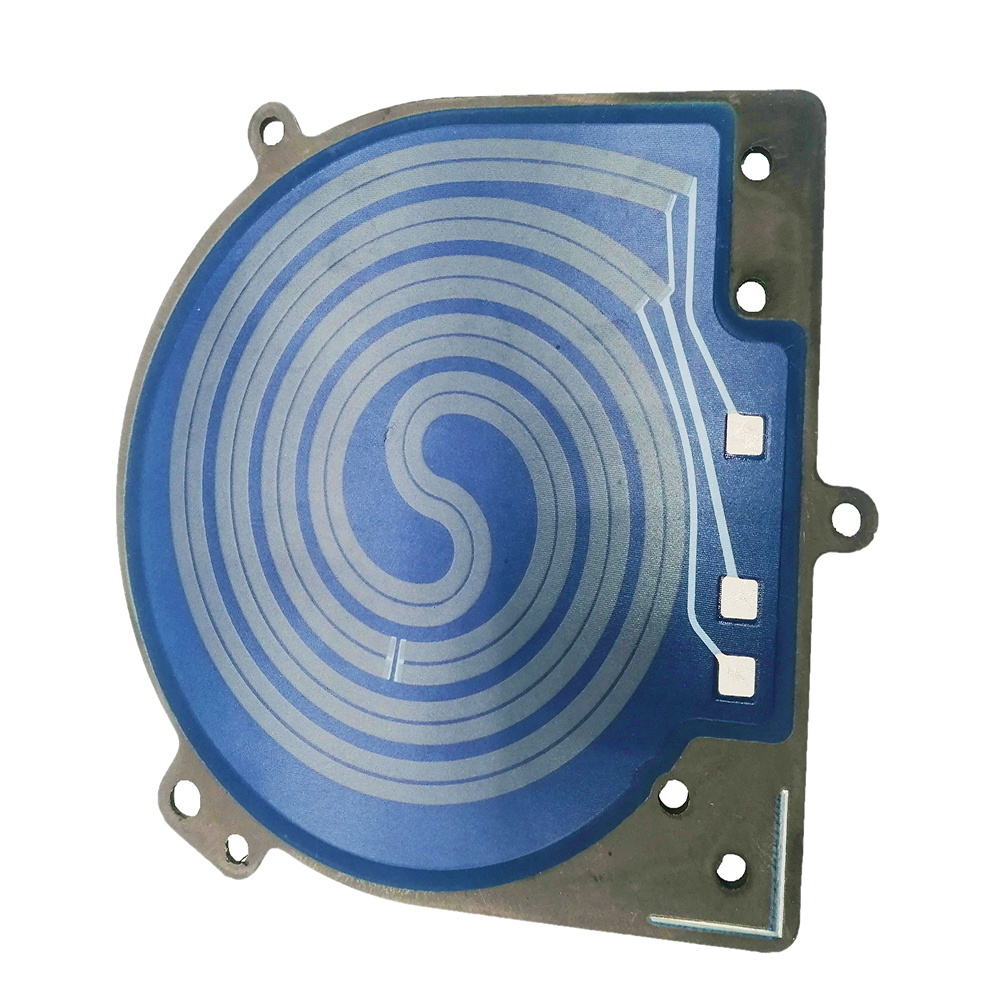

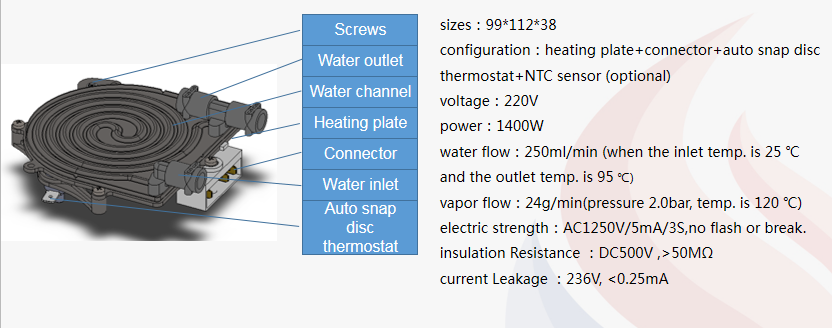

High Thermal Efficiency Thick Film Heating Element Electric Heater Plate

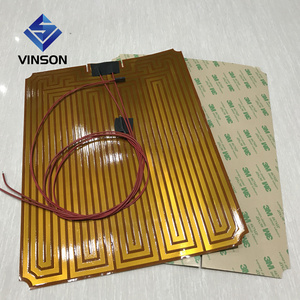

The Rare-Earth Metal Thick Film is one of today's most innovation and forward-looking solution for electric heating field.

Compared with Aluminum Cast and Immersion Heating Element, Thick Film Heating Element is higher in power density(60W/cm²), quicker temperature ramp up rate(80℃/S) and better thermal transfer (96%).

Compared with Aluminum Cast and Immersion Heating Element, Thick Film Heating Element is higher in power density(60W/cm²), quicker temperature ramp up rate(80℃/S) and better thermal transfer (96%).

Thick Film Heating Circuit printed on the back side of the kettle bottom. Due to it's much thinner, it saves much space and deliver more possibility for new model research and design.

For applications where space is limited, this simple profile heater offers high thermal power density and fast response times to heat up or cool down (due to low thermal mass).

It's printed Silver Conductor and spot weld connected with wires.

It's printed Silver Conductor and spot weld connected with wires.

|

Plate Diameter

|

144mm

|

|

Heat Intensity

|

>60W/cm²

|

|

Ramp-Up Rate

|

80℃/s

|

|

Thermal Efficiency

|

>96%

|

|

Heating Power

|

1.5KW

|

|

Service Life

|

>10,000 hours

|

|

Rated Voltage

|

220v

|

|

Certificate

|

CQC, RoHS

|

|

Electric Intensity

|

1,500V/5mA/60s

|

|

Power Deviation

|

-10% - +5%

|

|

Leakage Current

|

≤0.25mA

|

|

Insulation Resistance

|

≥200MΩ

|

|

Shield

|

PA66+ glass fibre, temperature resistance≥250℃

|

|

Snap Action Thermostat

|

16A, installed close to the heating tube's heating circuit

|

Main Features

1.

Electric Circuit printed on stainless steel plate

2. Large heat transfer area on tube surface; Ramp up and Cool down quickly; High utilization rate up to 93% or above.

3. Fast temperature response, power density is as high as 60W/cm² and heating circuit's temperature raising rate exceeds 80℃/s.

4. Simple structure, compact profile.

2. Large heat transfer area on tube surface; Ramp up and Cool down quickly; High utilization rate up to 93% or above.

3. Fast temperature response, power density is as high as 60W/cm² and heating circuit's temperature raising rate exceeds 80℃/s.

4. Simple structure, compact profile.

Thick Film Stainless Steel Tube.

Customize Service

1. Substrate: SUS 430, 316

2. Tube diameter, Tube length, Power, Thermostat, Control Board, etc are available for customer design.

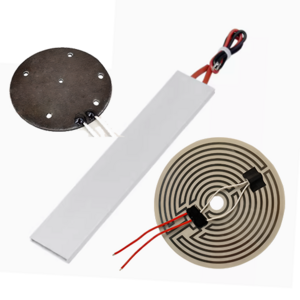

Related Products

Certifications

CustomerApplications

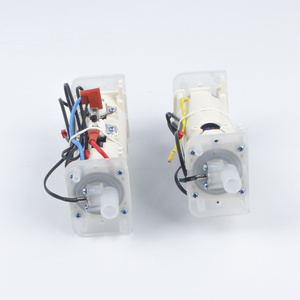

At present, thick film heating tube(heating body) of GIDAPE® ANDETONG® series has been successfully applied to fluid heating field, such as: instant hot water dispenser, quick hot water boiler, pipeline machine, electric heat faucet, kitchen under sink water heater, milk machine, coffee machine, industrial equipment and so on.

About us

Jieda locates in Xinxiang, Henan Provience, is founded in 2012, is a high-tech manufacturer that specializes in design, research, produce and sales rare-earth metal thick film electric heating tubes/elements.

What is Jieda advanced in?

1. More than 8 years experiences in thick film electric heating tubes.

2. Fully mastery of thick film tube surface screen printing and sintering.

3. Main Process Flow in 10000+ Grade Air Purification Workshop.

4. First manufacturer to mass produce Thick Film Electric Heating Tube/Element in China

5. Available various Solutions for fluid heating, especially for Instant Water Heating Home Appliances, House Floor Heating and Industrial water flow heating.

6. Monthly production capacity is up to 300,000 pcs.

What is Thick Film Heating Tube/Element advanced in?

1. The tubular structure makes it possible to instant heat water flow inside tube, by the Electric Heating Circuit printed and sintered on the tube surface.

2. It can work more than 10,000 hours, in case of no DRY HEATING.

3. The thermal transfer rate no less than 97%.

4. Power Density is up to 60w/cm²

5. Temperature Ramp-Up Rate up to 80~150℃/S.

6. Boiling water(95℃) is available in 3 seconds around.

7. Simple & compact profile brings more possibility in new products research and design.

Those thick film heating tubes/elements are widely applied in Instant Water Boiling Heater, Instant Water Kettle, Water Dispensers, Coffee Maker/Machine, Electric Heating Faucets, Industrial Water Flow Heating, etc.

It can successfully replace Traditional Electric Heating Tubes/Elements, change their structures and performance completely, which can reduce energy consumption and save space.

What is Jieda advanced in?

1. More than 8 years experiences in thick film electric heating tubes.

2. Fully mastery of thick film tube surface screen printing and sintering.

3. Main Process Flow in 10000+ Grade Air Purification Workshop.

4. First manufacturer to mass produce Thick Film Electric Heating Tube/Element in China

5. Available various Solutions for fluid heating, especially for Instant Water Heating Home Appliances, House Floor Heating and Industrial water flow heating.

6. Monthly production capacity is up to 300,000 pcs.

What is Thick Film Heating Tube/Element advanced in?

1. The tubular structure makes it possible to instant heat water flow inside tube, by the Electric Heating Circuit printed and sintered on the tube surface.

2. It can work more than 10,000 hours, in case of no DRY HEATING.

3. The thermal transfer rate no less than 97%.

4. Power Density is up to 60w/cm²

5. Temperature Ramp-Up Rate up to 80~150℃/S.

6. Boiling water(95℃) is available in 3 seconds around.

7. Simple & compact profile brings more possibility in new products research and design.

Those thick film heating tubes/elements are widely applied in Instant Water Boiling Heater, Instant Water Kettle, Water Dispensers, Coffee Maker/Machine, Electric Heating Faucets, Industrial Water Flow Heating, etc.

It can successfully replace Traditional Electric Heating Tubes/Elements, change their structures and performance completely, which can reduce energy consumption and save space.

Packing & Delivery

|

Packaging

|

|

|

|

Size (m)

|

1.2 (L) * 1 (W) * 1.2 (D)

|

|

|

Weight

|

0.5 T

|

|

|

Packaging Details

|

The normal package is carton box, placed on wooden tray.

|

|

Hot Searches