- Product Details

- {{item.text}}

Quick Details

-

Printing Type:

-

all kinds of flexo machine

-

Weight (KG):

-

50

-

Place of Origin:

-

Shandong, China

-

Brand Name:

-

JCT

-

Series:

-

rodillo anilox

-

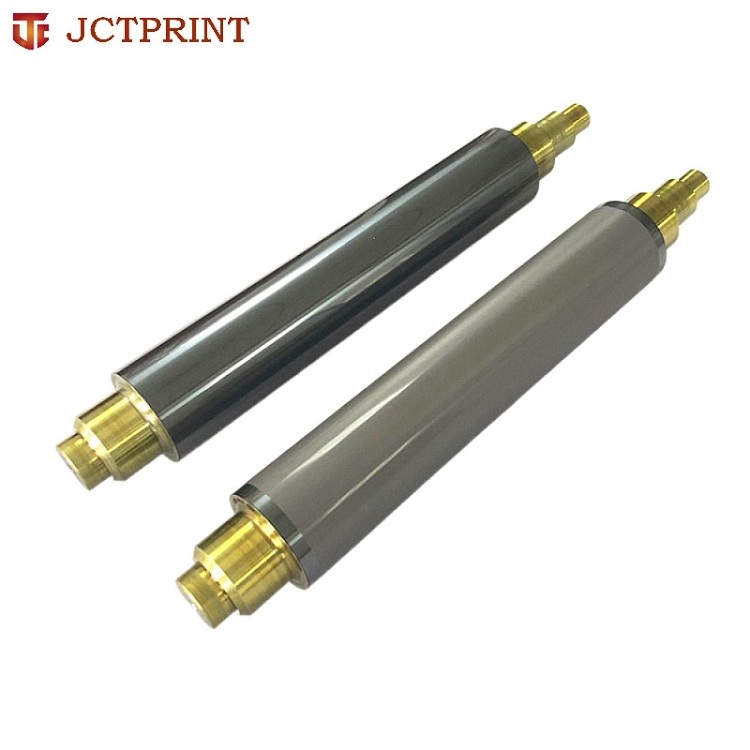

material:

-

#45 seamless steel tube or No.5 series aluminum

-

Screen count range:

-

80-2000 LPI

-

Maximum width:

-

5500mm ( with axis)

-

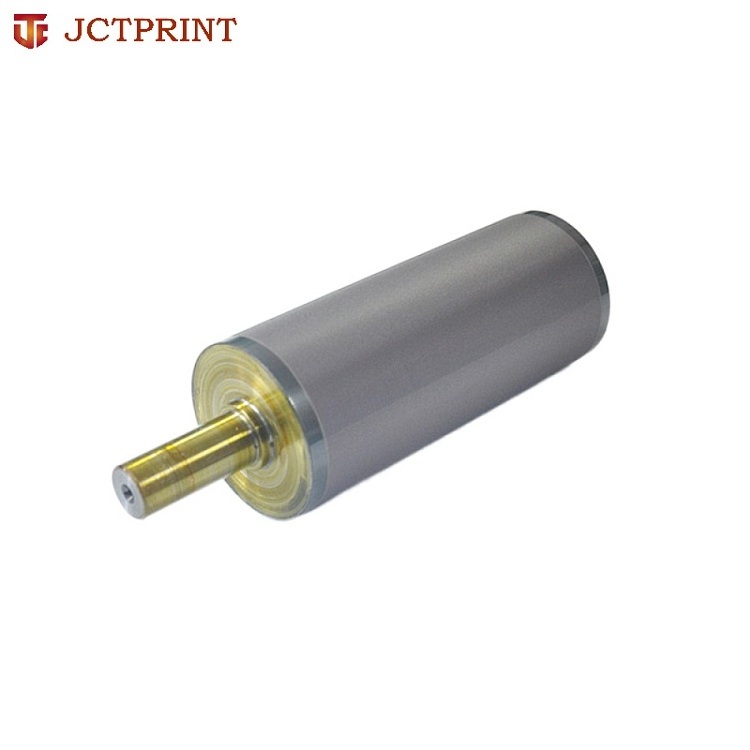

Diameter range:

-

25-600 mm

-

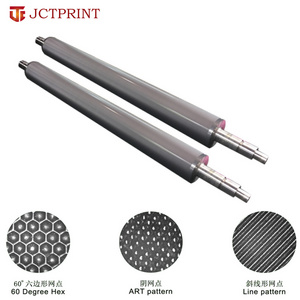

Screen angle:

-

1-89 degree

-

Cell shape:

-

according to customers' requirement

-

Ceramic type:

-

chrome oxide ceramics

-

Ceramic hardness:

-

1200HV

Quick Details

-

Condition:

-

New

-

Type:

-

Roller

-

Use:

-

all kinds of flexo machine

-

Printing Type:

-

all kinds of flexo machine

-

Weight (KG):

-

50

-

Place of Origin:

-

Shandong, China

-

Brand Name:

-

JCT

-

Series:

-

rodillo anilox

-

material:

-

#45 seamless steel tube or No.5 series aluminum

-

Screen count range:

-

80-2000 LPI

-

Maximum width:

-

5500mm ( with axis)

-

Diameter range:

-

25-600 mm

-

Screen angle:

-

1-89 degree

-

Cell shape:

-

according to customers' requirement

-

Ceramic type:

-

chrome oxide ceramics

-

Ceramic hardness:

-

1200HV

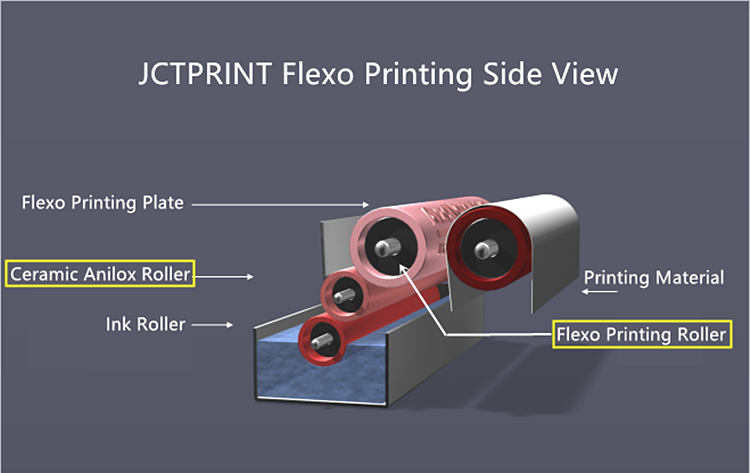

flexo printing manufacturer steel metal rolo rodillo anilox coating ceramic cylinders roller rollers roll shaft price

A. Flexo printing machine(unit type ,central cylinder type,cascade type)

B. Offset printing machine

C. Corrugated water-based ink printing slotting machine

D. Coating and lamination machine

E. Glazing machine ect.

|

Screen count range |

80-2000 LPI

|

surface material |

chrome oxide ceramic |

|

Maximum width |

5500mm ( with axis) |

surface hardness |

1250HV-1350HV |

|

Diameter range |

25-600 mm |

Maximum effective length |

3800mm-4250mm |

|

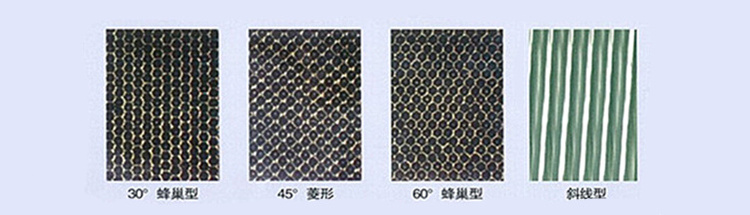

Screen angle |

1-89 degree |

Material of base roller |

45#steel |

|

Cell shape : hexagon , quadrangle and line , etc or according to your actual requirement |

|||

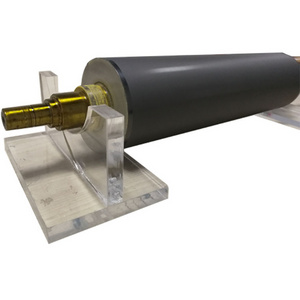

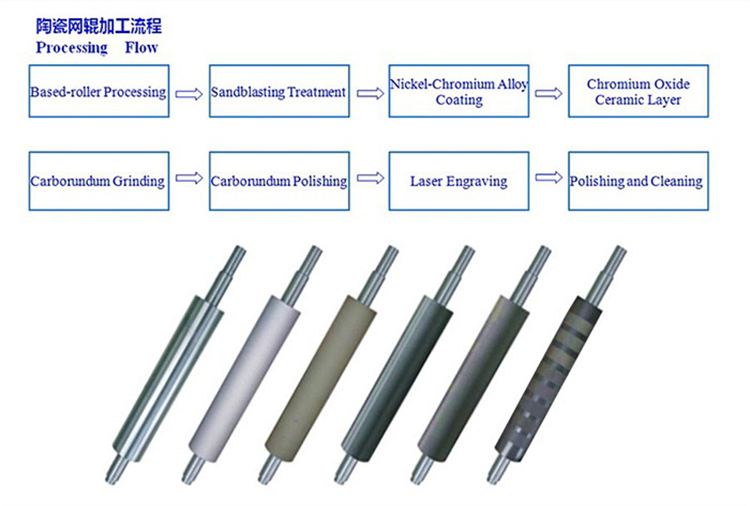

Processing Flow of ceramic anilox roller

1. Base roller

A. Material: 45# steel tube or No.5 series aluminum

General performance requirement:45# steel tube

Lighter weight requirement : No5 series aluminum

B.Thickness : 15mm-25mm

We can also make the special thickness according to customers requirement.

C. A strict inspection procedure of base roller:

Incoming inspection including surface roughness,straightness, dynamic balance,cylindricity and so on.

2. Chrome oxide ceramic layer

A. Using the famous plasma spraying machine from Switzerland supplier.

B. The evenness of 80% ceramic powder can be controlled between 15u-35u

C. The hardness of chrome oxide ceramics can reach 1200HV.

3. Antiseptic treatment

we use the nanoscopic sealant to coat on the surface of the ceramic which can reach the tiny cell to protect the base roller from solvent corrosion.

4. Precise delivery on the inks

First,we make trial engraving before the real engraving.

Second,we use the scanner to scan each layer to test the volume of the cell

Third,according to the relationship between the LPI and BCM , we can make sure whether the LPI is workable.

5. Quality Control

We have the quality control system during the whole production from the very beginning to the end to make sure each roller is qualified. And we will issue the certification for our customers after the products are finished.

6. Service life

Under nomal operation and maintenance ,our ceramic anilox rollers can work 8-10years or even longer.