- Product Details

- {{item.text}}

Quick Details

-

Voltage:

-

Customers Local Voltage

-

Power:

-

Multi Power, Multi Power

-

Dimension(L*W*H):

-

Customer Request

-

Warranty:

-

1 Year warranty

-

Equipment Name:

-

Plastic Vacuum Metallizing Coating Machine with Ion Plasma Treatment

-

Basis Technology:

-

PVD Vacuum Aluminum Filaments Resistance Evaporation

-

Fixture:

-

Fixture can be custom

-

Application:

-

Decorative Metal-like Coatings for plastic decorations and metallizing

-

Material of Substrates:

-

Can be kinds of plastic, glass, papers

-

Available Industries:

-

Plastic Decorations, toys, cell phone industry, plastic parts, etc

-

Leak rate of working chamber:

-

Precisely made working chamber with leakage rate less than 0.5 Pa/h

-

Coatings:

-

High quality and shiny reflective aluminum coatings

-

Size of vacuum chamber:

-

1000X1100mm, 1200X1400mm, 1600X1800/2000mm or customized

-

Weight:

-

3-15 tons

-

Certification:

-

CE

Quick Details

-

Machine Type:

-

PVD Coating Mahcine - Vacuum Metallizing

-

Place of Origin:

-

Hunan, China

-

Brand Name:

-

Hongfeng VAC

-

Voltage:

-

Customers Local Voltage

-

Power:

-

Multi Power, Multi Power

-

Dimension(L*W*H):

-

Customer Request

-

Warranty:

-

1 Year warranty

-

Equipment Name:

-

Plastic Vacuum Metallizing Coating Machine with Ion Plasma Treatment

-

Basis Technology:

-

PVD Vacuum Aluminum Filaments Resistance Evaporation

-

Fixture:

-

Fixture can be custom

-

Application:

-

Decorative Metal-like Coatings for plastic decorations and metallizing

-

Material of Substrates:

-

Can be kinds of plastic, glass, papers

-

Available Industries:

-

Plastic Decorations, toys, cell phone industry, plastic parts, etc

-

Leak rate of working chamber:

-

Precisely made working chamber with leakage rate less than 0.5 Pa/h

-

Coatings:

-

High quality and shiny reflective aluminum coatings

-

Size of vacuum chamber:

-

1000X1100mm, 1200X1400mm, 1600X1800/2000mm or customized

-

Weight:

-

3-15 tons

-

Certification:

-

CE

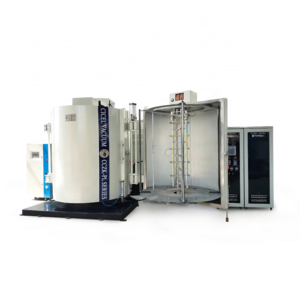

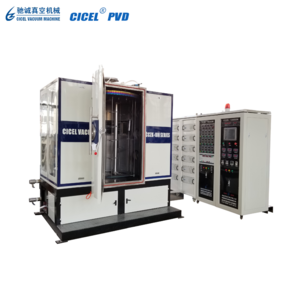

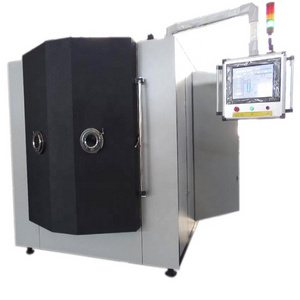

Plastic Vacuum Metallizing Coating Machine with Ion Plasma Treatment

This machine can apply metallizing coatings on plastic, ceramic, glass, and metal items.

Vacuum metallization is a form of physical vapor deposition, meaning that metal is combined with a non-metallic substrate through evaporation. Aluminum is the most commonly used metal in the process due to its aesthetic and functional properties.

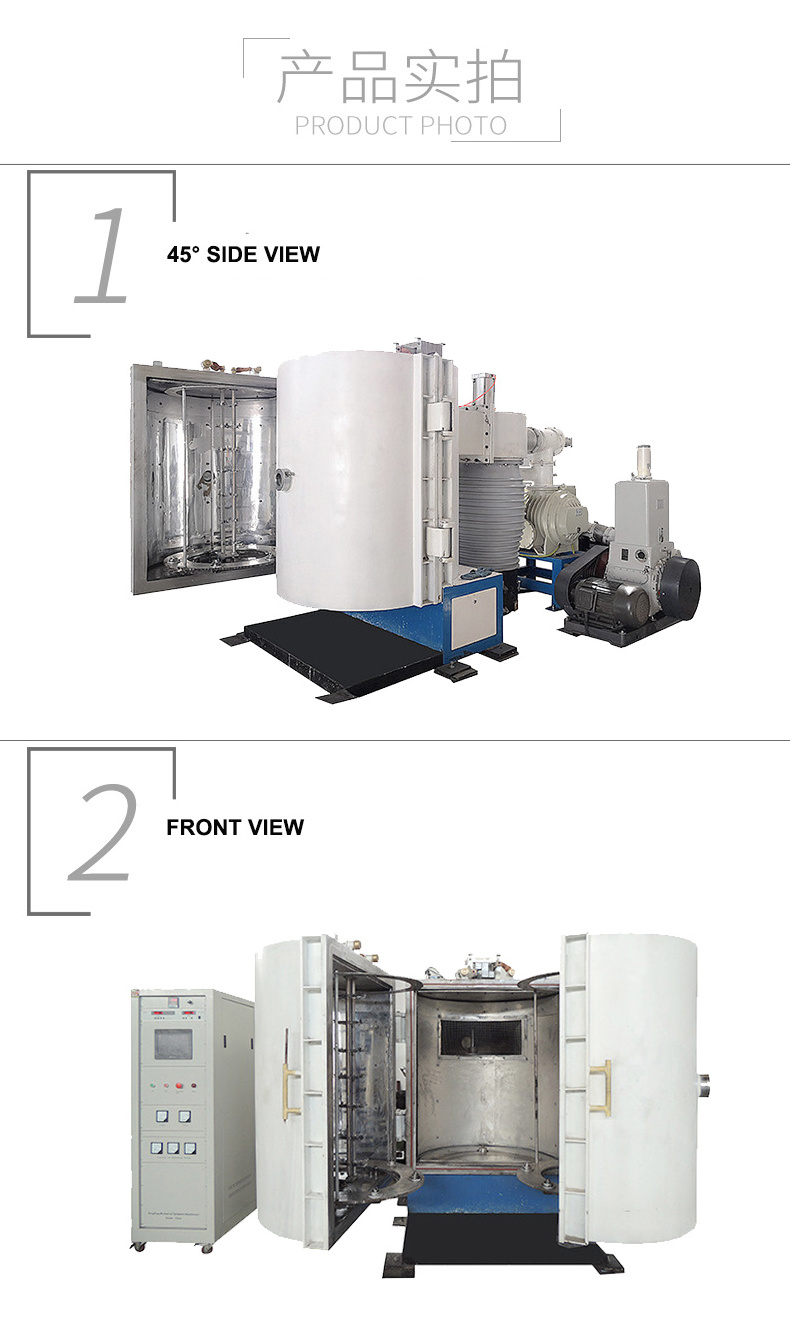

| Photos of the vacuum metallizing machine |

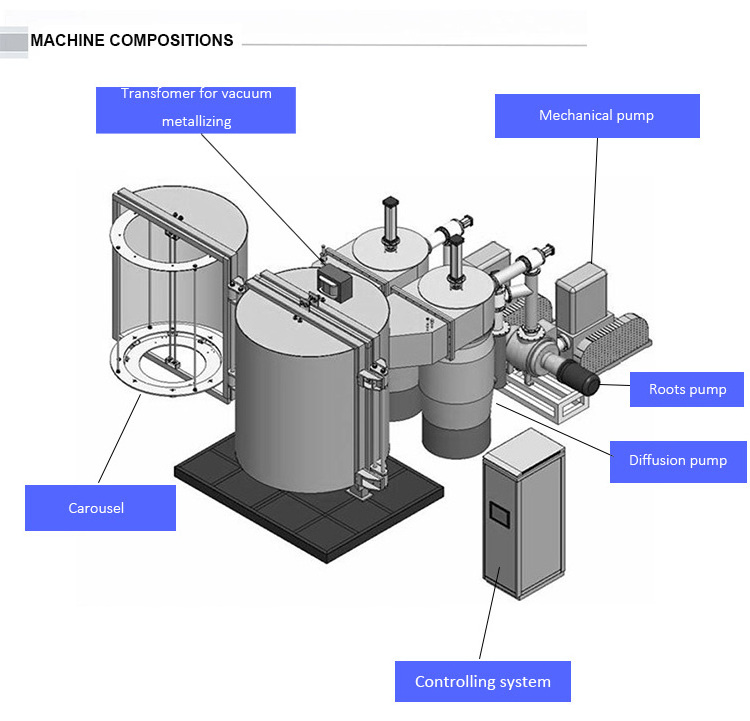

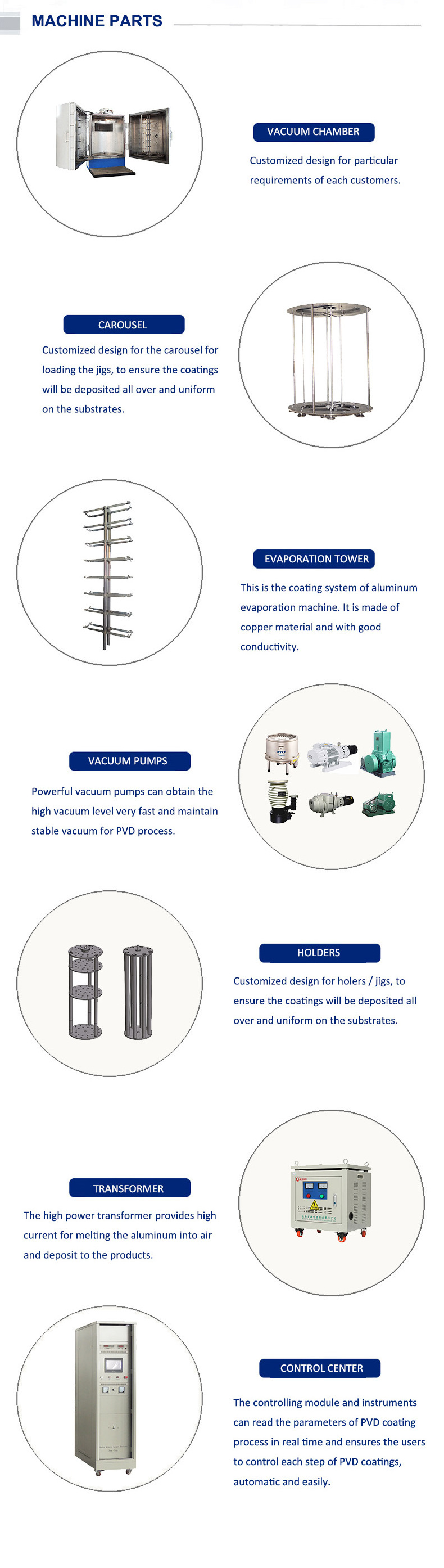

| Structure of the Evaporation Metallizing Machine |

1. Vacuum Metallizing Machine - Technical Specifications:

| Mode | EV-1000 | EV-1200 | EV-1600 | EV-1800 |

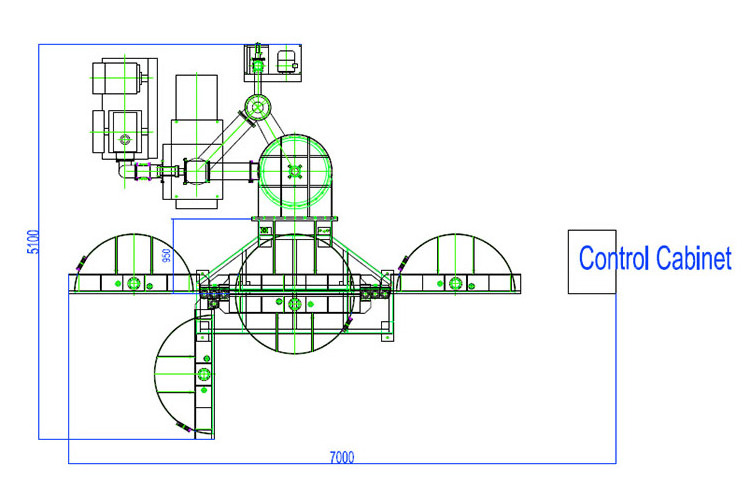

| Dimension | D1000*H1100mm | D1200*H1400mm | D1600*H2000m | D1800*H2000m |

| Main Applications | Plastic or glass metallizing, decorative coatings | |||

| Coating System | Evaporation Coating System with high power transformer | |||

| Vacuum chamber structure | Vertical chamber front opening door, one or two doors, as well as two chambers optional | |||

| Pumping system |

Diffusion pump(Molecular pump) +Roots pump +Mechanical pump

(5.0*10-4Pa) |

|||

| Workpiece Carousel | Public rotation Frequency control: 0-20RPM | |||

| Vacuum degree measuring | Digital display composite vacuum gauge: from atmosphere to 8.0*10-4Pa | |||

| Control mode | Manual/Automatic work mode by PLC touched screen | |||

| Remark |

We can make the machine according to customer’s requirements. |

|||

Note: We can provide the complete solutions for this whole process.