- Product Details

- {{item.text}}

Quick Details

-

Material:

-

Copper/Silicon steel /Cast iron

-

Cooling type:

-

IC06,IC17,IC37,ICW37

-

Insulation:

-

F

-

working duty:

-

S1

-

Protection:

-

IP21S,IP23,IP44

-

PTC:

-

PT100/PTC140

-

standard:

-

GB/IEC

-

Motor excitation mode:

-

Separate excitation

-

Mounting type:

-

B35

-

output shaft:

-

single

Quick Details

-

Speed(RPM):

-

965/2000rpm

-

Efficiency:

-

Ie 3

-

Place of Origin:

-

Zhejiang, China

-

Material:

-

Copper/Silicon steel /Cast iron

-

Cooling type:

-

IC06,IC17,IC37,ICW37

-

Insulation:

-

F

-

working duty:

-

S1

-

Protection:

-

IP21S,IP23,IP44

-

PTC:

-

PT100/PTC140

-

standard:

-

GB/IEC

-

Motor excitation mode:

-

Separate excitation

-

Mounting type:

-

B35

-

output shaft:

-

single

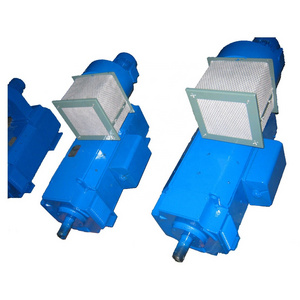

| Z4 Series DC Motor | ||

| Protection Class | IP21S.IP23 and IP44 can be negotiated | |

| Rated Speed | 3000,1500,1000,750,600,500,400,300,200r/min. total nine grades | |

| Standard Rated Voltage | 1 60V/440V. 220V/400V/660V or other Voltage may be derived on request | |

| Electric Motor Mounting Type | ||

| IMB3 | Z4-100~Z4-450 | Horizontal foot mounted |

| IM35 | Z4-100~Z4-350 | Horizontal flanged foot mounted |

| IMV-1 | Z4-100~Z4-225 | Vertical flanged mounted |

| IMV-51 | Z4-100~Z4-315 | Vertical flanged and foot mounted |

| Duty: ContinuousS1 | ||

| Methods of Cooling: IC06, IC17, IC37 and ICW37A86, Other types of protection and cooling required by customers can be negotiated. | ||

| Performance Condition |

| Altitude above sea level maximal 1,000m; |

| Cooling air temperature maximal 40 o C |

| Ambient conditions for electric motors should be free from acidic, alkali fumes or other aggressive gases which corrode insulation. |

| Duty: Continuous (SI); |

| Monthly average temperature would not be more than 24 degree celsius.and r elative humidity: monthly average no more than 85%. |

VIEW MORE>>> VIEW MORE>>> VIEW MORE>>>

VIEW MORE>>> VIEW MORE>>> VIEW MORE>>>

Z4 Series Medium Size DC electric motor is newly developed product of our works.

These dc electric motors are found wide use for prime mover in various machinery.

such as mill auxiliary in metallurgical industry, metal cutting machine-tool, paper making, print, textile, printing and dyeing, cement-making, plastic extruding machine , etc .

All sets of electric motor adopt the advanced production technology and quality raw material.

At the same time we strictly to control every production link from punching, laminating, welding, machining, winding, embedded line, dipping, assembled to test ,

All the procedures are done in-house to ensure motors high quality .

| Inner packing | 3-4 layers moisture sealer or per clients request |

| Outer packing | plywood case |

Over 60 years of combined experience have made Hengli an expert in handling the additional complexities of DC/AC electric motor repair.

Includes step-by-step disassembly, detailed inspections and measurements to identify any electrical and mechanical damage.

All mechanical repairs on shafts, bearing journals, end bells, etc., are handled in-house by experienced machinists with over 60 years of combined experience.

As a reflection of our uncompromising commitment to customer satisfaction, all of Hengli's workmanship is 100% guaranteed according to GB standards.

Q: What is the payment terms?

A: 30% T/T in advance, 70% before shipment, L/C at sight

Q: What is your delivery time?

A: different type with different time, 30-90 days after order confirm

Q: What is your MOQ of this item ?

A: 1 set per item.

Q: Where is your loading port ?

A: Shanghai or Ningbo Port, China.

Q: What is your production capacity?

A: About 15000 set per month.