- Product Details

- {{item.text}}

Quick Details

-

Rolling thinckness:

-

0.5-1.5mm

-

Place of Origin:

-

Liaoning, China

-

Brand Name:

-

PRO

-

Voltage:

-

380V

-

Dimension(L*W*H):

-

8900x2230x2300(mm)

-

Weight:

-

9000 kg

-

Warranty:

-

13 months

-

Feeding width:

-

914mm

-

Marketing Type:

-

Hot Product

-

After-sales Service Provided:

-

Overseas service center available

-

Feeding Width::

-

914mm

-

Effective Width::

-

610mm

-

Controlling system::

-

PLC&Mechanical

-

Step of rollers::

-

14 steps

-

Proper span::

-

4-38m

-

suitable plate:

-

0.5-1.5mm

-

Type::

-

K type span roll forming machine

-

Certification:

-

CE

-

Control system:

-

PLC(detla) System

Quick Details

-

Type:

-

Arching Machine

-

Tile Type:

-

Steel

-

Production Capacity:

-

100 sets/year

-

Rolling thinckness:

-

0.5-1.5mm

-

Place of Origin:

-

Liaoning, China

-

Brand Name:

-

PRO

-

Voltage:

-

380V

-

Dimension(L*W*H):

-

8900x2230x2300(mm)

-

Weight:

-

9000 kg

-

Warranty:

-

13 months

-

Feeding width:

-

914mm

-

Marketing Type:

-

Hot Product

-

After-sales Service Provided:

-

Overseas service center available

-

Feeding Width::

-

914mm

-

Effective Width::

-

610mm

-

Controlling system::

-

PLC&Mechanical

-

Step of rollers::

-

14 steps

-

Proper span::

-

4-38m

-

suitable plate:

-

0.5-1.5mm

-

Type::

-

K type span roll forming machine

-

Certification:

-

CE

-

Control system:

-

PLC(detla) System

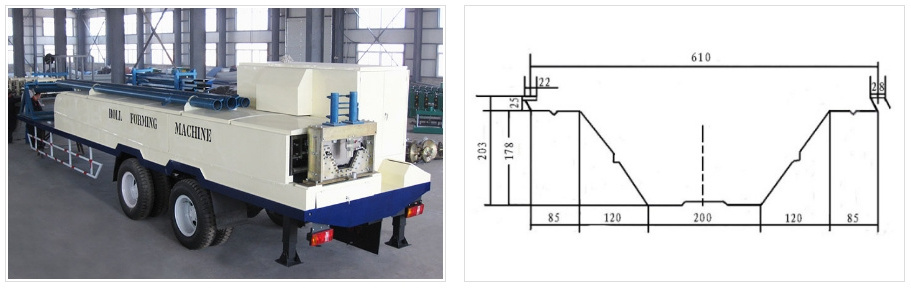

No-girder Arch Building Roll Forming Machine/Curving Roofing Machine

| Main Technical Specifications | |

| Size | |

| Feeding width | 914mm |

| Proper span | ≤38m |

| Total weight | About 15000kg |

| Effective width | 610mm |

| Sheet operating factor | 66.7% |

| Total power | 21.5kw |

| Cutting power | 4.0kw |

| Forming power | 7.5kw |

| Bending power | 4.0kw+1.1kw×2 |

| Sewing power | 2.2kw |

| Controlling system | PLC and manual |

| Cutting mode | Hydraulic cutting |

| Depth of the groove | 203mm |

| Corollary equipment | Equipped with generator |

| Material of roller shaft | 45#steel,galvanized |

| Material of rollers | 45#steel,quenched with hard chrome |

Detail forming roller and bending leaves

Characteristics

- The rollers and shafts are both solid, the rollers are made by 45# steel plated with hard chromium.

- The thickness of our arch shaping leaf is 10mm, the process of manufacture for our arch shaping leafs are controlled by computer.

- The length of the finished sheet is measured by the electronic measurement instrument or mechanical measurement instrument.

- Our machine can be divided in to two cutting ways, one is hydraulic, and the other is mechanical. Controlling system include manual and automatic. It can be also designed according to your requirement.

- Our helping hand wheel and the counter are used in adjustment of the bending of arch sheet, which makes the operation simpler.

- Our hoisting tool is light and handy; the weight of hoisting tool of our company is 2KG. It is convenient to install and uninstall the hoisting tool. Its hoisting speed is quick.

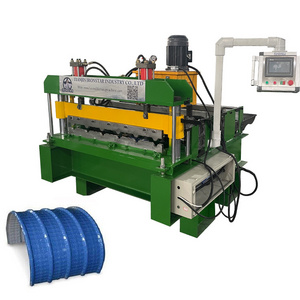

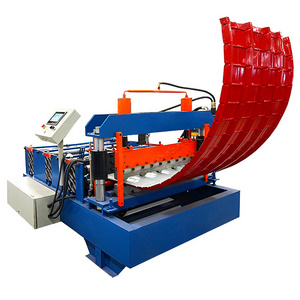

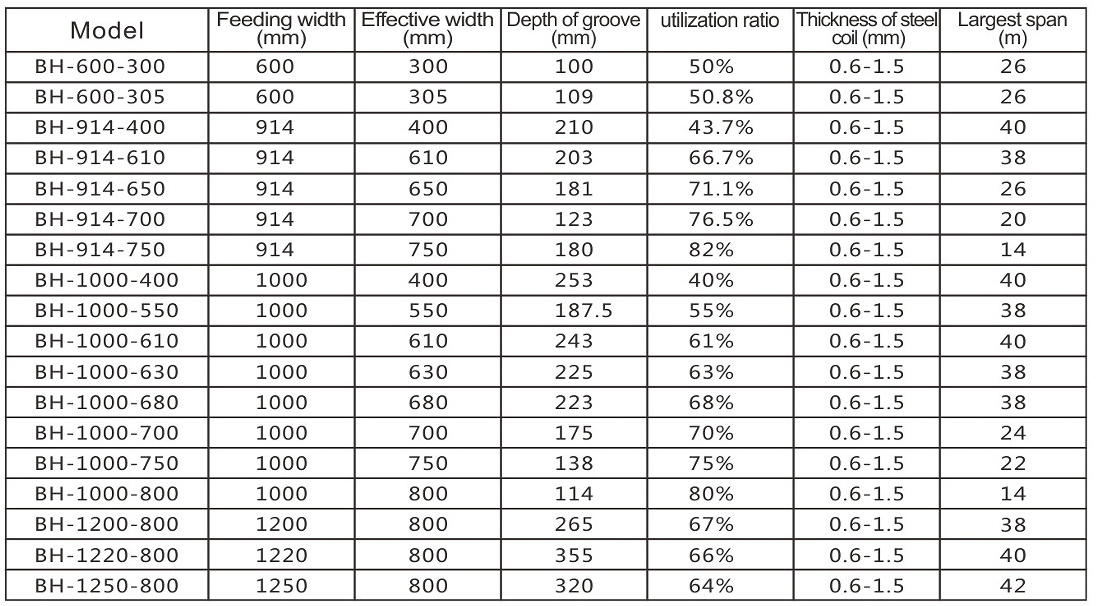

Relative products

Working process

Yingkou Bohai Machinery Equipment Manufacture Co., Ltd. is a roll forming machine manufacturer and supplier since 2000. With more than 20 years of experience in producing roll forming machines, we have the capability to produce high quality arch sheet roll forming machines, helping our customers design and execute the arch sheet projects, as well as other types of roll forming machines. We sincerely invite you to visit our company and know more about our arch sheet roll forming machine.

Founded in 2000, Bohai is the first company in China that carries out research and production of arch sheet roll forming machines. Our more than 20 years of experience have taught us how to make durable and highly productive arch sheet roll forming machines. So far, our arch sheet roll forming machines have been exported to Ukraine, Afghanistan, UAE, India, Iraq, Angola, Guinea and more countries. Welcome you visit Bohai to know more about the qualified arch sheet roll forming machine.

Exhibition photos

FAQ

Q: Can you make the machine according to my design or photo type?

A: Yes, we have an experienced team for working out the most suitable design and production plan for the machine according to your demand or photo type that you are going to book with us.

Q: Are you a factory or trading company?

A: We are a factory located in YingKou city, LiaoNing Province, China. Our city is near Beijing. All clients from abroad and home are warmly welcome to visit our factory!

Q: How do you guarantee the quality of the products?

A: Every section of our production has strict manufacture process, than professional inspectors check every section of the production, next the production will work for testing quality, which must be 100% quality assurance. Unqualified resolute don't a better factory.

Q: What is your service?

A:

We provide the technical support for whole life.

Pre-sales service includes i

nquiry and design support and view our factory.

After-sales service includes t

raining how to instal the machine, training how to use the machine, and engineers available to service machinery overseas.