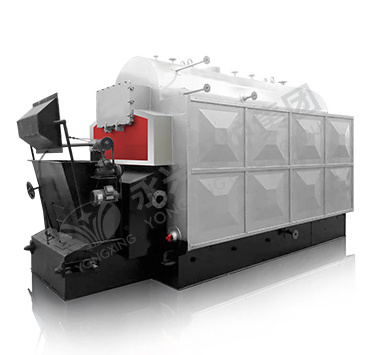

DZL biomass boiler is a single-drum vertical

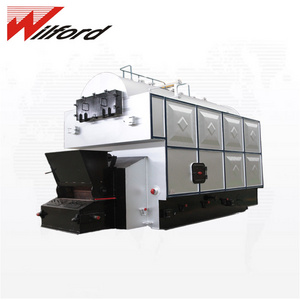

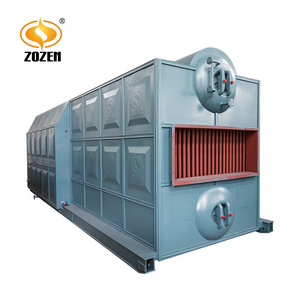

biomass boiler.DZL series quick-installed chain grate biomass boilers are single-drum vertical chain grate boilers. It is suitable for burning briquette biomass fuel, but also pure coal or mixed coal and briquette biomass fuel. There is an economizer at the rear. The

excluded ash and slag can be directly used as farmyard manure, which is a high-efficiency, energy-saving and environmentally

friendly product.

- Product Details

- {{item.text}}

Quick Details

-

Dimension(L*W*H):

-

customization for this solid fuel boiler

-

Weight:

-

5-30ton for this solid fuel boiler

-

Product name:

-

Coal Biomass Steam Boiler

-

Capacity:

-

1 2 3 4 5 6 8 10 12 15 20 ton

-

Application:

-

Industrial Production

-

Heat efficiency:

-

83%

-

Steam temperature:

-

184/194/205/225

-

Type of boiler:

-

Horizontal Steam Boiler

-

Certification:

-

ISO CE

-

Fuel Type:

-

Coal Biomass Wooden Fired

-

Design pressure:

-

1.25Mpa(13bar)

-

Boiler Structure:

-

3Pass

Quick Details

-

Core Components:

-

Other

-

Place of Origin:

-

Henan, China

-

Brand Name:

-

Yongxing

-

Dimension(L*W*H):

-

customization for this solid fuel boiler

-

Weight:

-

5-30ton for this solid fuel boiler

-

Product name:

-

Coal Biomass Steam Boiler

-

Capacity:

-

1 2 3 4 5 6 8 10 12 15 20 ton

-

Application:

-

Industrial Production

-

Heat efficiency:

-

83%

-

Steam temperature:

-

184/194/205/225

-

Type of boiler:

-

Horizontal Steam Boiler

-

Certification:

-

ISO CE

-

Fuel Type:

-

Coal Biomass Wooden Fired

-

Design pressure:

-

1.25Mpa(13bar)

-

Boiler Structure:

-

3Pass

Products Description

Title goes here.

Equipped with a blower and induced draft fan for mechanical ventilation, and equipped with a screw slag extractor to achieve mechanical slag extraction, complete control and monitoring instruments, and safe and reliable boiler

operation.

This type of boiler uses biomass pellets processed from crop wastes such as straw, sawdust, peanut shells, etc. as fuel. The new furnace design is used to maximize the combustion of fuel. The thermal efficiency of the boiler reaches 82.6%. The waste is used as suitable fuel, and the ash after combustion can also be used as farmyard manure. It is an environmentally friendly product withhigh efficiency and energy saving.

operation.

This type of boiler uses biomass pellets processed from crop wastes such as straw, sawdust, peanut shells, etc. as fuel. The new furnace design is used to maximize the combustion of fuel. The thermal efficiency of the boiler reaches 82.6%. The waste is used as suitable fuel, and the ash after combustion can also be used as farmyard manure. It is an environmentally friendly product withhigh efficiency and energy saving.

Product Paramenters

|

Boiler model |

Rated

capacity |

Rated

pressure |

Rated

tempe- |

Exhaust

tempe- |

Boiler

efficiency |

Fuel

comsum- |

Design

weight |

Design

dimension |

|

|

|

|

|

|

|

|

|

|

|

|

ton/h

|

Mpa

|

℃

|

℃

|

%

|

kg

|

ton

|

mm

|

|

DZL1

|

1

|

1.25/1.6/2.5/3.82 |

194/204226/450 |

109

|

>82 |

187

|

15.2

|

5230*2000*2780

|

|

DZL2

|

2

|

|

|

131

|

|

375

|

23.8

|

5950*2400*3150

|

|

DZL4

|

4

|

|

|

140

|

|

758

|

27

|

6829*2620*3524

|

|

DZL6

|

6

|

|

|

139

|

|

1125

|

40

|

8170*3180*3804

|

|

DZL8

|

8

|

|

|

138

|

|

1508

|

45

|

8130*3300*3950

|

|

SZL10

|

10

|

|

|

153

|

|

2150

|

24

|

7645*3180*3526

|

|

SZL12

|

12

|

|

|

149

|

|

2400

|

24.3

|

9258*3294*3524

|

|

SZL15

|

15

|

|

|

150

|

|

2568

|

24.7

|

11010*3300*2200

|

|

SZL20

|

20

|

|

|

148

|

|

4267

|

26

|

16680*6200*8420

|

|

SZL25

|

25

|

|

|

151

|

|

4675

|

26.5

|

17550*7300*8900

|

|

SZL30

|

30

|

|

|

147

|

|

5610

|

27

|

18230*7600*9200

|

|

SZL40

|

40

|

|

|

152

|

|

7450

|

27.8

|

18750*8500*9600

|

Details Images

Perormance Characteristics

*

Using threaded smoke pipe for heat transfer, which improves thermal efficiency and reduces energy consumption

* The application of membrane water wall structure improves the heat transfer coefficient and heat transfer effect and reduces heat loss

* The threaded smoke pipe is set in the pot shell, the overall air leakage is small, and the heat loss of exhaust smoke is small

* The welds of the boiler adopt advanced submerged arc automatic welding process to ensure the welding quality

Dust collector is arranged in the tail flue to ensure that the smoke and dust discharge meets environmental protection

requirements

* High level of automation, with automatic water adjustment, low water level interlock protection, high and low water level alarm and other functions

* Advanced arch design, forming an obvious inverted "α" flame, which is beneficial to the combustion of inferior coal and has strong adaptability to coal types

* Complete control and monitoring instruments, boiler operation is safe and reliable

* The setting of the two-wing flue allows the flue gas to enter the front smoke box smoothly, so that the temperature of the previous tube sheet is the same, and avoids cracks in the tube sheet due to temperature stress

* The grate adopts a new type of small scale grate, which adds a unique safety ring, which makes the grate run stably and

reliably, and improves the combustion efficiency

* The application of membrane water wall structure improves the heat transfer coefficient and heat transfer effect and reduces heat loss

* The threaded smoke pipe is set in the pot shell, the overall air leakage is small, and the heat loss of exhaust smoke is small

* The welds of the boiler adopt advanced submerged arc automatic welding process to ensure the welding quality

Dust collector is arranged in the tail flue to ensure that the smoke and dust discharge meets environmental protection

requirements

* High level of automation, with automatic water adjustment, low water level interlock protection, high and low water level alarm and other functions

* Advanced arch design, forming an obvious inverted "α" flame, which is beneficial to the combustion of inferior coal and has strong adaptability to coal types

* Complete control and monitoring instruments, boiler operation is safe and reliable

* The setting of the two-wing flue allows the flue gas to enter the front smoke box smoothly, so that the temperature of the previous tube sheet is the same, and avoids cracks in the tube sheet due to temperature stress

* The grate adopts a new type of small scale grate, which adds a unique safety ring, which makes the grate run stably and

reliably, and improves the combustion efficiency

Hot Searches