- Product Details

- {{item.text}}

Quick Details

-

Power:

-

4KW

-

Dimension(L*W*H):

-

7100*5400*3400(1200KGS)

-

Weight:

-

2000 KG

-

Production Capacity:

-

120

-

Name:

-

Fabric dyeing machine

-

Capacity:

-

10kg to 400kg

-

Heat:

-

Electric, steam

-

Pressure:

-

0.4-0.6Mpa

-

Used for:

-

Laundry dyeing

-

Operation:

-

Easy

-

Manual book:

-

Provided

-

Service:

-

Good

-

Installation:

-

Free-standing

Quick Details

-

Voltage:

-

380V

-

Place of Origin:

-

Jiangsu, China

-

Brand Name:

-

Tong Yang

-

Power:

-

4KW

-

Dimension(L*W*H):

-

7100*5400*3400(1200KGS)

-

Weight:

-

2000 KG

-

Production Capacity:

-

120

-

Name:

-

Fabric dyeing machine

-

Capacity:

-

10kg to 400kg

-

Heat:

-

Electric, steam

-

Pressure:

-

0.4-0.6Mpa

-

Used for:

-

Laundry dyeing

-

Operation:

-

Easy

-

Manual book:

-

Provided

-

Service:

-

Good

-

Installation:

-

Free-standing

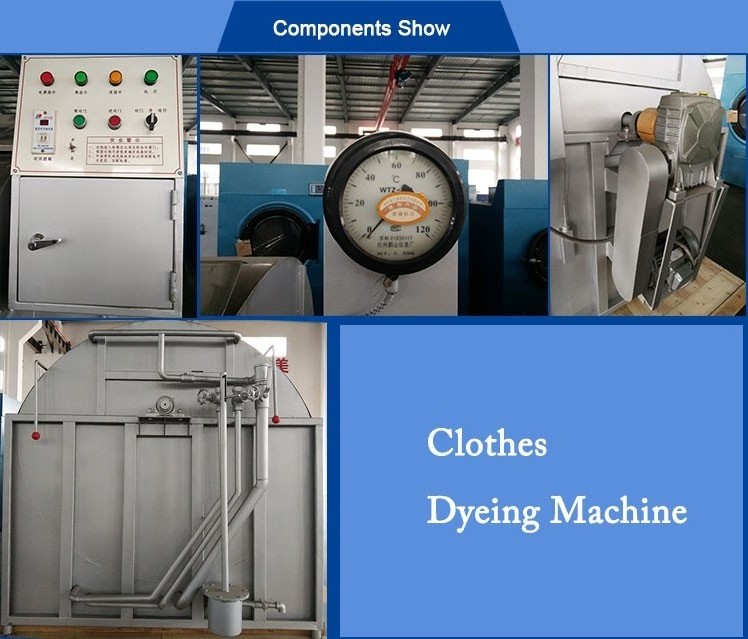

Fabric dyeing machine(CE,ISO)

Specification:

| Type |

Max. capacity

(Kg) |

Drum Dimension

(mm) |

Speed

(r/min) |

Power

(Kw) |

Overall Dimension

(mm) |

Steam pressure

(Mpa) |

Water consumption per time (Kg) |

| GXF30 | 30 | 660×800 | 5-33 | 1.1 | 1500×1100×1300 | 0.4-0.6 | 520 |

| GXF50 | 50 | 800×980 | 5-33 | 1.5 | 1750×1200×1500 | 0.4-0.6 | 620 |

| GXF70 | 70 | 950×1220 | 5-33 | 2.2 | 2050×1400×1850 | 0.4-0.6 | 750 |

| GXF100 | 100 | 960×1420 | 5-33 | 3 | 2300×1400×1850 | 0.4-0.6 | 920 |

| GXF150 | 150 | 1060×1650 | 5-33 | 4 | 2500×1500×1900 | 0.4-0.6 | 1100 |

| GXF200 | 200 | 1080×2000 | 5-33 | 5.5 | 2900×1500×2000 | 0.4-0.6 | 1430 |

Description:

1. The machine is suitable for wool, polyester, nylon, rayon, knitwear,etc. dyeing processing.

2. The liquid cylinder is using high quality contact and highly resistant to corrosion of the 202'' stainless steel plate manufacturing, to ensure that no pollution fabric, durable.

3. Dyeing tank wall and paddle wheel are surface polishing treatment, ensure that the fabric is not compromised.

4. According to different fabric dyeing requirements and heavy, but through without for electrical devices to any high speed rotating speed paddle.

5. Dyeing process all by starting to stop all by electric box button operation, the dyeing time can be by the time the automatic control, dyeing time can be adjusted according to the different needs in advance.

6. Through the power of the positive and negative turn to be automatic controller, make dyeing tank paddle wheel fall within the rotation, the liquid flow changes and the fabric, so as to improve the dyeing effect.

7. According to different dyeing process requirements, in the crock bottom installation direct or indirect steam pipes to heat, heat preservation effect.