- Product Details

- {{item.text}}

Quick Details

-

Brand Name:

-

Henan Huansheng

-

Weight:

-

1000 KG

-

Marketing Type:

-

Hot Product 2023

-

Product name:

-

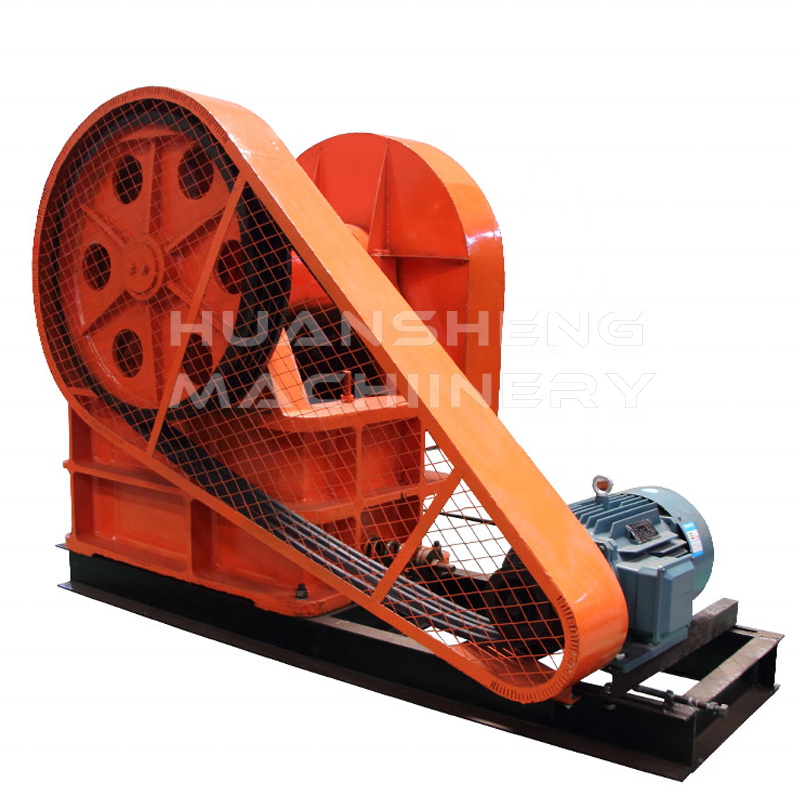

Jaw Crusher Machine For The Stone

-

Keyword:

-

Rock Breaking Machine

-

The Machines classification:

-

Crushing Line

-

Function:

-

Rock Breaker Crush Machine

-

Usage:

-

Crushing Work

-

Raw material:

-

Stones Rocks Ores

-

Color:

-

Customer Requirement

-

Applicaton:

-

Rock Crusher Processing

-

Advantage:

-

Longer Service Life

-

Processed Materials:

-

200 Kinds Materials(<320 Mpa)

Quick Details

-

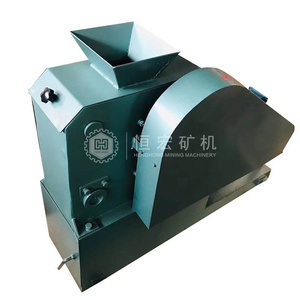

Application:

-

Gold Mining

-

Capacity(t/h):

-

20-30

-

Place of Origin:

-

Henan, China

-

Brand Name:

-

Henan Huansheng

-

Weight:

-

1000 KG

-

Marketing Type:

-

Hot Product 2023

-

Product name:

-

Jaw Crusher Machine For The Stone

-

Keyword:

-

Rock Breaking Machine

-

The Machines classification:

-

Crushing Line

-

Function:

-

Rock Breaker Crush Machine

-

Usage:

-

Crushing Work

-

Raw material:

-

Stones Rocks Ores

-

Color:

-

Customer Requirement

-

Applicaton:

-

Rock Crusher Processing

-

Advantage:

-

Longer Service Life

-

Processed Materials:

-

200 Kinds Materials(<320 Mpa)

Product Display

Our stone crusher machine, a type of

jaw crusher

is widely used in mining, railway construction, water conservancy project, metallurgy, chemical, building material industries. It is mainly used to crush rock and ore, whose compression strength is less than 320 Mpa. Jaw crusher, your preferred primary crusher, is used for coarse crushing and fine crushing.

We can provide you with free process design.

Features

* The lubrication system is safe and reliable, easy to replace parts, and the equipment maintenance is simple.

* Crushing cavity is deep and there is no dead zone, so as to improve the feed capacity and output.

* Energy-saving equipment: the single can save 15% ~ 30% energy, and the system can save double energy at least.

* The discharge gate has wide adjustable range and can meet the requirements of different users.

* Crushing cavity is deep and there is no dead zone, so as to improve the feed capacity and output.

* Energy-saving equipment: the single can save 15% ~ 30% energy, and the system can save double energy at least.

* The discharge gate has wide adjustable range and can meet the requirements of different users.

Product Parameters

|

Model

|

Feeder Opening Size(mm)

|

Max. Feeding Size (mm)

|

Discharging Opening Size(mm)

|

Capacity (t/h)

|

Motor Power (kw)

|

Overall Dimension (mm)

|

|

PE400x600

|

400x600

|

350

|

40-90

|

15-60

|

30

|

1700x1750x1680

|

|

PE500x750

|

500x750

|

425

|

50-100

|

40-130

|

45

|

2150x1900x1950

|

|

PE600x900

|

600x900

|

500

|

60-125

|

90-180

|

55

|

2500x2010x2350

|

|

PE750x1060

|

750x1060

|

630

|

60-150

|

110-380

|

110

|

2630x2310x3110

|

|

PE900x1200

|

900x1200

|

750

|

95-165

|

220-450

|

132

|

3720x2850x3250

|

|

PE1000x1200

|

1000x1200

|

850

|

200-300

|

280-560

|

160

|

3820x2850x3250

|

|

PE1200x1500

|

1200x1500

|

1020

|

150-300

|

400-800

|

220

|

3710x3446x4075

|

|

PE1500x1800

|

1500x1800

|

1200

|

210-360

|

520-1100

|

280

|

5100x4700x4300

|

Main Structure

Huansheng Small Portable Rock Crusher For Sale Rock Breaking Machine Jaw Crusher Machine For The Stone

PE Jaw Crusher Working principle

Two jaw plates are the work parts of jaw crusher: the first is fixed jaw, fixed on the front wall

of the body vertically (or the upper part inclines outward slightly).

The other is the movable jaw, inclined. It and the fixed jaw

compose of the crushing chamber (the working chamber), whose upper part is bigger, while the bottom is smaller.

The movable jaw

plate makes periodic alternating motion to the fixed jaw plate, thus they are separated and close to each other in turn.

When they

are separated, the material enters the crushing chamber and the finished product is discharged from the lower part.

When they are

close to each other, the material between two jaw plates is crushed by being extruded, bent and split.

How to choose a crusher?

There are several characteristics to consider:

The abrasiveness and hardness factor

. It is essential to know what material is going to be crushed, in particular its abrasiveness and hardness.

You must evaluate the

compressive strength or maximum force

that the material can withstand before breaking.

Granulometric requirement.

It is necessary to define the desired result i.e. the grain size after crushing. The capacity (throughput). You will need to determine the processing capacity (or throughput) necessary for your use. This is measured in tonnes/hour.

Application scenario

Jaw crushers

use a rudimentary and reliable technology that does not require much maintenance or engineering knowledge. They are

the most popular crushers in the world. Jaw crushers are particularly suitable when the main objective is to reduce large blocks

into smaller pieces that can then be processed by other machines.

Packaging & Shipping

Ways of Packing:

1. Sand blasting, coat with high quality paint;

2. Product wrap by PP-Bubble

3. Load container, Spare Parts in wooden case.

Transportation:

1. By sea Freight;

2. MSK/MSC/APL/EMC/WANHAI/KLINE

3. We will remind you before boat arrival

Hot Searches