- Product Details

- {{item.text}}

Quick Details

-

Voltage:

-

380V or as your requirements

-

Dimension(L*W*H):

-

3500x2150x1870

-

Power (kW):

-

30kw

-

Weight (KG):

-

11000 kg

-

Applicable Industries:

-

woodworking machinery

-

Factory direct sales:

-

with low price

-

Certification:

-

CE,ISO

-

Power(W):

-

40kw

-

Weight:

-

10000kg

Quick Details

-

Place of Origin:

-

Shandong, China

-

Type:

-

plywood machinery

-

Brand Name:

-

BSY

-

Voltage:

-

380V or as your requirements

-

Dimension(L*W*H):

-

3500x2150x1870

-

Power (kW):

-

30kw

-

Weight (KG):

-

11000 kg

-

Applicable Industries:

-

woodworking machinery

-

Factory direct sales:

-

with low price

-

Certification:

-

CE,ISO

-

Power(W):

-

40kw

-

Weight:

-

10000kg

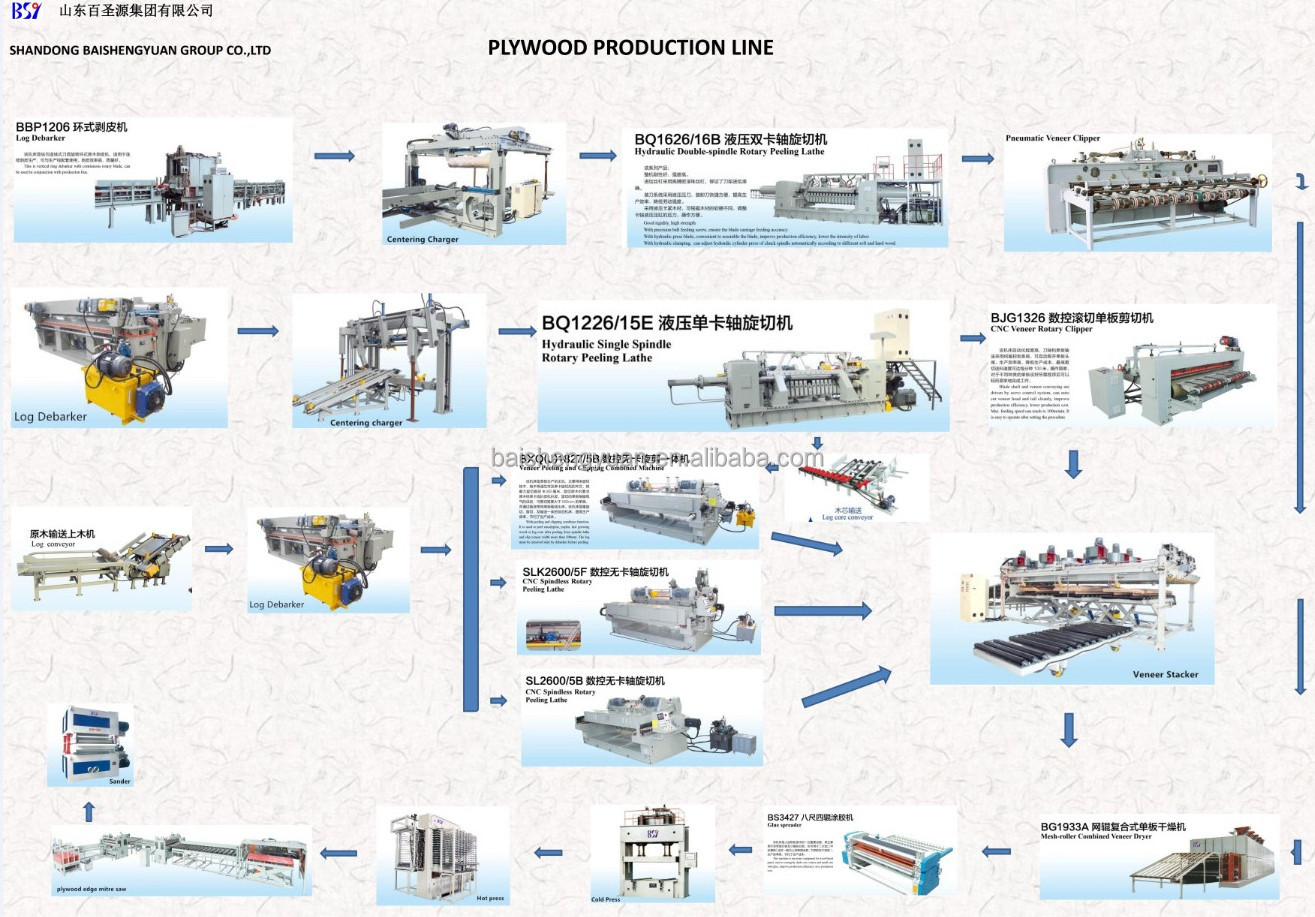

Automatic Plywood production line

Plywood Production Technology:

1) Log cutting:

Usually import log length is more than 6 meters. Cutting according to the technology required length and quality. The cutting length should be product length add remains. For example, product is 1220mm*2440mm, cutting length usually be 2600mm or 1300mm. log length, camber and demerit affect plywood output directly. Remains are small wood pieces, truncations, sawdust, tec. Log cutting wastage ratio is 3%-10%.

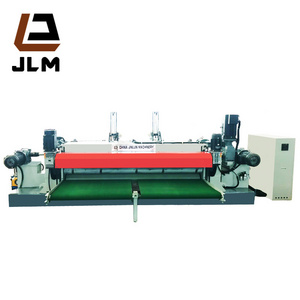

2)Veneer peeling:

Peeling is the most popular plywood producing process. Back veneer thickness is about 0.6mm, core veneer and centre veneer thickness is about 1.8mm.

| Model | BXQ(J)1813/5B | BXQ(J)1827/5B |

| Max.cutting length | 1350mm | 2600mm |

| Max.cutting diameter | 480mm | 480mm |

3) Drying:

Veneer is moist. it should be dried according to the technology requirement. After drying, it will shrink. Dimension will become smaller. Veneer length, width, thicknesswill shrink. Shrink wastage is related to wood material, moisture containing, veneer thickness. Shrink wastage is 4%-10%.

4) Veneer gluing and handling:

Handling include cutting, putting veneer together and mending. Cut zonal veneer into specification veneer or proper size which can be put together. Narrow zonal veneer can be put together into one veneer. Veneer with demerit can be mended to be qualified. Wastage in this part related to log material, peeled veneer quality, dried quality, and worker operation skill. Wastage ratio is 4%-16%. Import veneer processing plywood wastage ratio is 2%-11%.

5) Cold and Hot press:

Veneer be glued and stacked, then glue together under set temperature and pressure by hot press. As veneer temperature and moisture containing changes, veneer will shrink. Shrink wastage is related to temperature, pressure, hot press time, wood material, moisture containing,wastage ratio is 3%-8%

6) Edge trimming:

Trimming the edge of the plywood flank from hot press to qualified plywood board. Remains related to process remains and product dimension. Production is bigger, wastage is smaller.Wastage ratio is 6%-9%

7) Sanding:

Sanding plywood surface to make it good. Wastage is powder. Veneer quality is good, sanding is less. Wastage ratio is 2%-6%

Other machines

We can also provide other machines, just like veneer jointer machine, knife grinder and so on.

Wood log saw cutting machinery

wood log debarking and rounding machinery

Veneer peeling&clipping combined machine

Cold Press Machine

Hot press machine

About Us:

SHANDONG BAISHENGYUAN GROUP CO.,LTD

1. Leading manufacturer of woodworking machinery in China, found in 1956. specialize in this field for more than 60 years.

2. Almost 30 year export experience, exported dozens of countries in Asia, Europe, Africa and America. All products are quite popular among clients.

3. Specializing in plywood production line and finger joint board production line . We have our own designers to meet any of your requirement.

4. Having own after –sale maintenance center , our engineer can go to overseas for installation and commissioning.

Any questions,please feel free contact with us: