- Product Details

- {{item.text}}

Quick Details

-

Place of Origin:

-

Jiangsu, China

-

Brand Name:

-

Youwei

-

Voltage:

-

customized

-

Dimension(L*W*H):

-

200x200x200

-

Marketing Type:

-

New Product 2024

-

Weight (KG):

-

100 kg

-

Product name:

-

Vacuum Powder Conveyor Machine

-

After-sales Service Provided:

-

Video Technical Support

-

Application:

-

Powder

-

Usage:

-

Food Industry Equipment

-

Name:

-

Vacuum Feeder

-

Function:

-

Conveying Dry Powder granules

-

Key words:

-

Powder granules transform conveying

-

Keyword:

-

Powder Feeder conveyor

Quick Details

-

Power:

-

7.5KW, 7.5kw

-

Warranty:

-

1 Year

-

Width or Diameter:

-

2100mm

-

Place of Origin:

-

Jiangsu, China

-

Brand Name:

-

Youwei

-

Voltage:

-

customized

-

Dimension(L*W*H):

-

200x200x200

-

Marketing Type:

-

New Product 2024

-

Weight (KG):

-

100 kg

-

Product name:

-

Vacuum Powder Conveyor Machine

-

After-sales Service Provided:

-

Video Technical Support

-

Application:

-

Powder

-

Usage:

-

Food Industry Equipment

-

Name:

-

Vacuum Feeder

-

Function:

-

Conveying Dry Powder granules

-

Key words:

-

Powder granules transform conveying

-

Keyword:

-

Powder Feeder conveyor

Product Description

Shanghai YouWei Powder Equipent CO.,LTD VACUUM CONVEYOR

A vacuum conveyor is a type of material handling system that uses air pressure to transport bulk materials, such as powders,granules, and pellets, through a sealed pipe or tube. It's a versatile and efficient way to move materials over long distances orto challenging locations.

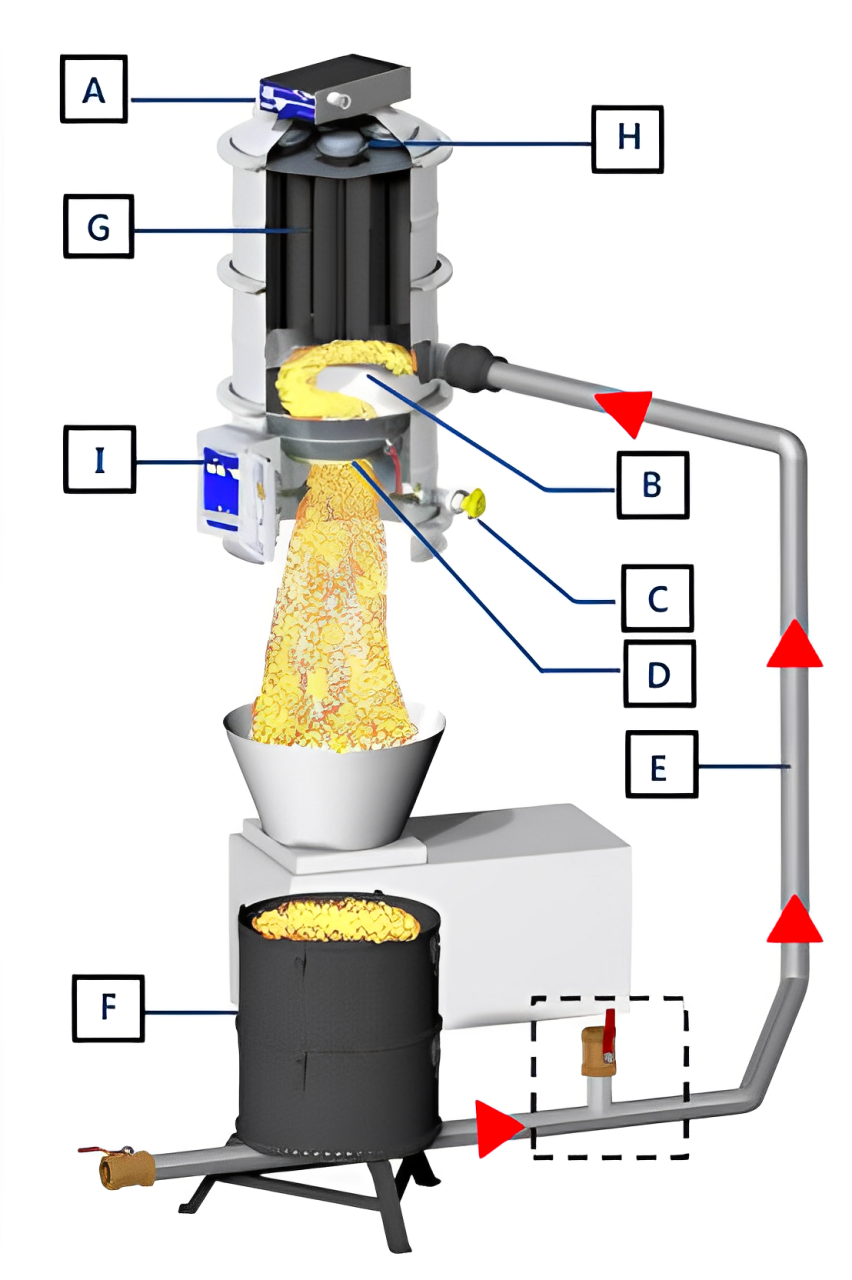

Working principal:

The vacuum feeder uses the negative pressure airflow generated by the vacuum equipment to suck the material from the feed port.

The air and materials are then separated in the filter chamber of the vacuum feeder. The materials fall automatically due to

gravity and are collected in the silo. Our cyclones prevent fine powder from entering the filter to increase filter efficiency.

When the silo is filled with materials, the vacuum pump automatically shuts down and the pressure in the conveying equipmentreaches equilibrium. The discharge valve opens, and the material flows out through the discharge port and falls directly into thestorage container. When discharging, the filter element is automatically cleaned by the back-flushed air bag. If the material isrelatively viscous, we can install a special vibrator to assist in unloading. After unloading, the discharging chamberautomatically closes and the entire conveying process starts again

The air and materials are then separated in the filter chamber of the vacuum feeder. The materials fall automatically due to

gravity and are collected in the silo. Our cyclones prevent fine powder from entering the filter to increase filter efficiency.

When the silo is filled with materials, the vacuum pump automatically shuts down and the pressure in the conveying equipmentreaches equilibrium. The discharge valve opens, and the material flows out through the discharge port and falls directly into thestorage container. When discharging, the filter element is automatically cleaned by the back-flushed air bag. If the material isrelatively viscous, we can install a special vibrator to assist in unloading. After unloading, the discharging chamberautomatically closes and the entire conveying process starts again

Composition accessories

*

Gentle handling:

Ideal for fragile materials like food, powders, and chemicals.

* Enclosed transport: Minimizes dust and spills, improving safety and cleanliness.

* Flexible routing: Pipes can navigate complex layouts and reach to Receiving bin.

* Wide range of materials: Handles bulk solids, liquids, and slurries.

* Enclosed transport: Minimizes dust and spills, improving safety and cleanliness.

* Flexible routing: Pipes can navigate complex layouts and reach to Receiving bin.

* Wide range of materials: Handles bulk solids, liquids, and slurries.

Technical Parameter

|

Type

|

Spectification

(MM)

|

Conveying Capacity

KG/H

|

Power

KW

|

Filter Area

m²

|

Material

|

|

200

|

Φ250*600

|

≤250

|

2.2KW

|

0.35

|

304/316L

|

|

300

|

Φ300*1200

|

≤500

|

4KW

|

0.55

|

304/316L

|

|

400

|

Φ430*1500

|

≤1000

|

5.5KW

|

1.5

|

304/316L

|

|

500

|

Φ560*1800

|

≤2000

|

7.5KW

|

2.5

|

304/316L

|

|

800

|

Φ800*2000

|

≤3000

|

11KW

|

4.6

|

304/316L

|

|

1200

|

Φ1200*1600

|

≤5000

|

22KW

|

6.9

|

304/316L

|

Equipment production process

Certifications

Hot Searches