- Product Details

- {{item.text}}

Quick Details

-

Model Number:

-

js-1001

-

Product Name:

-

Injection Plastic Household Mould

-

Application:

-

Household Product Mold

-

Surface treatment:

-

Powder Coating

-

Design software:

-

UG PROE CATIA SOLIDWORK CAD

-

Cavity:

-

Single Cavity\ Multiple Cavity

-

Mould material:

-

P20/718/738/NAK80/S136/2738/2316

-

Mould base:

-

LKM.HASCO. DME

-

Keyword:

-

Plastic Injection Mold Services

-

Certification:

-

ISO9001/TS16949/QS/ISO14001

-

Runner:

-

Hot Runner\Cold Runner

Quick Details

-

Shaping Mode:

-

Plastic Injection Mould

-

Place of Origin:

-

Guangdong, China

-

Brand Name:

-

OEM

-

Model Number:

-

js-1001

-

Product Name:

-

Injection Plastic Household Mould

-

Application:

-

Household Product Mold

-

Surface treatment:

-

Powder Coating

-

Design software:

-

UG PROE CATIA SOLIDWORK CAD

-

Cavity:

-

Single Cavity\ Multiple Cavity

-

Mould material:

-

P20/718/738/NAK80/S136/2738/2316

-

Mould base:

-

LKM.HASCO. DME

-

Keyword:

-

Plastic Injection Mold Services

-

Certification:

-

ISO9001/TS16949/QS/ISO14001

-

Runner:

-

Hot Runner\Cold Runner

|

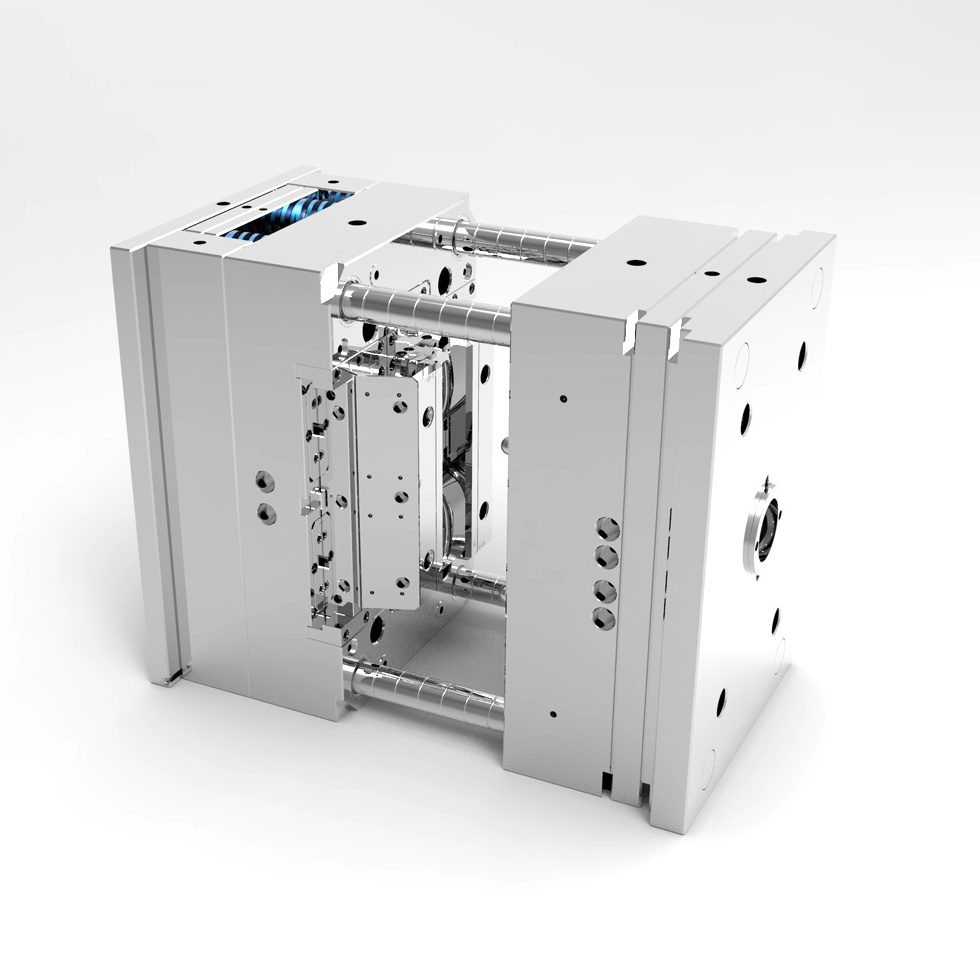

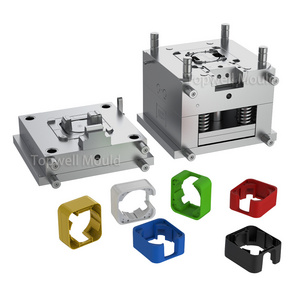

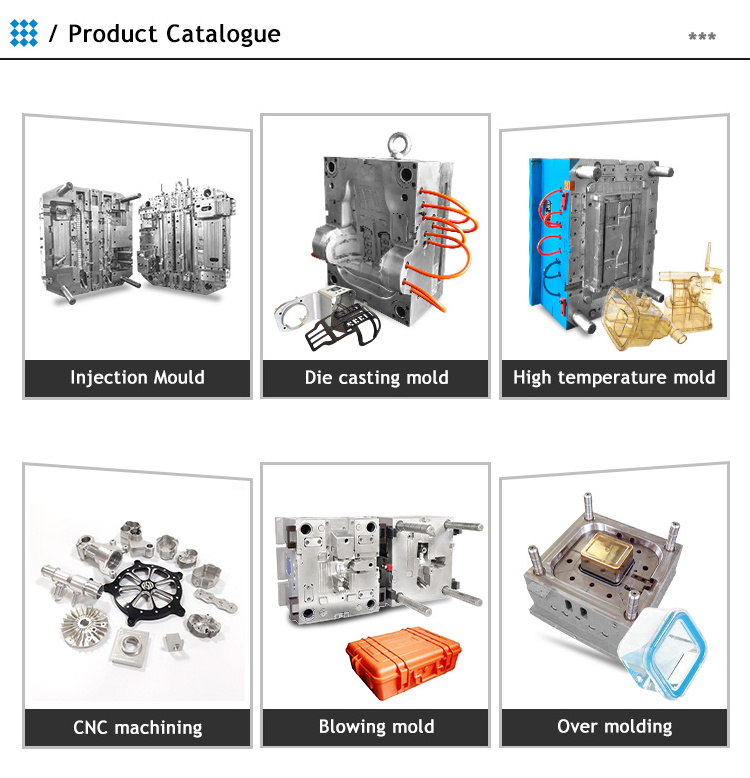

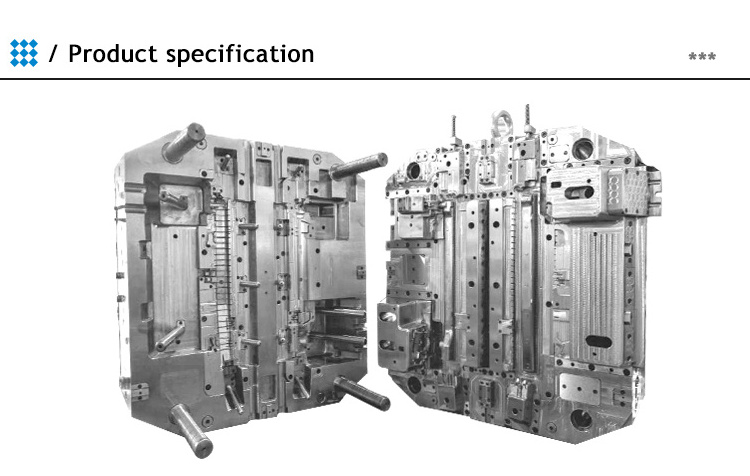

Product parameters

|

|

|

|

our service

|

Injection mould/Injection mold /Die casting mould /Plastic mold /Injectionmolding /CNC milling

|

|

|

Pls provide

|

2d/3d/sample lor the size of the multi-angle pictures

|

|

|

Mould Time

|

20-35 Days

|

|

|

Product time

|

7-15 Days

|

|

|

Moud precision

|

+/-0.01mm

|

|

|

Mould life

|

50-100 million shots

|

|

|

Producing Process

|

Audit drawings - mold flow analysis - design validation - Custom Materials -mold processing - core processing - electrode machining - Runner system

processing - parts processing and procurement - machining acceptance -cavity surface treatment process - complex mode Die - The entire moldsurface coating - Mounting plate - mold sample - sample test - sending samples

|

|

|

Mould cavity

|

One cavity, multi-cavity or same different products be made together

|

|

|

Mould material

|

P20,2738,2344,718,S136,8407,NAK80,SKD61,H13

|

|

|

Runner system

|

Hot runner and cold runner

|

|

|

Base material

|

P20,2738,2344,718,S136,8407,NAK80,SKD61,H13

|

|

|

Finish

|

Pitting the word, mirror finish, matte surface, striae

|

|

|

Standard

|

HASCO,DME or dependent upon

|

|

|

Main thechnology

|

Milling, grinding,CNC,EDM, wire cutting, carving,EDM, lathes, surface

|

|

|

Software

|

CAD,PRO-E,UG Design Time: 1-3 days (normal circumstances)

|

|

|

Product material

|

ABS,PP,PC,PA6,PA66,TPU,POM,PBT,PVC,HIPS,PMMA,TPE,PCIABS,TPV,TPO,TPR,EVA,HDPE,LDPE,CPVC,PV

|

|

|

Quality system

|

ISO9001:2015

|

|

|

Mould life

|

300000-1000000 shots

|

|

|

Equipment

|

CNC,EDM,Cutting off Machine,plastic machinery,etc plastic part

|

|

|

we promise

|

All customer-centric, never for short-term profit, and sell long-term benefits

|

|

Q: How can you confirm the plastic injection mold you produce is the onewe need ?

A: we can provide professional mold analysis reports before mold making.

--------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------

Q: what can we do if we don't have the mold drawing ?

A: you will only provide the actual sample to us then we can help you to makethe design injection mold drawings for your confirmation.

--------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------

Q: Can we test the plastic injection mold ?

A:after the mold is ok ,we can help you to test the mold for free.

--------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------

Q: Can you process the die-casting parts of injection mold ?

A: We can help to process die-casting parts for small run or mass production.

--------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------

Q: What about the plastic products samples are wrong ?

A: if you are not satisfied with the plastic sample, we can send the sample to you again for free.

--------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------

Hot Searches