- Product Details

- {{item.text}}

Quick Details

-

Slab Structure:

-

3-Layer Structure Boards

-

Place of Origin:

-

Shandong, China

-

Brand Name:

-

Zequan

-

Model Number:

-

ZQ-CHIP09

-

Product name:

-

Particlel board

-

Size:

-

1220x2440mm/1250x2550mm/1830x2750mm/as request

-

Thickness:

-

6-44mm

-

Glue:

-

E0/E1/E2/MELAMINE/MR/WBP

-

Core:

-

Poplar Pine Hardwood Combi

-

MOQ:

-

1*20GP

-

Surface Treatment:

-

Matt High Glossy UV Coated

-

PAYMENT:

-

30% Deposit + 70% Balance

-

Delivery time:

-

Within 15 Days Receiving Deposit

Quick Details

-

Project Solution Capability:

-

graphic design, Cross Categories Consolidation

-

Application:

-

Home Office

-

Grade:

-

FIRST-CLASS

-

Slab Structure:

-

3-Layer Structure Boards

-

Place of Origin:

-

Shandong, China

-

Brand Name:

-

Zequan

-

Model Number:

-

ZQ-CHIP09

-

Product name:

-

Particlel board

-

Size:

-

1220x2440mm/1250x2550mm/1830x2750mm/as request

-

Thickness:

-

6-44mm

-

Glue:

-

E0/E1/E2/MELAMINE/MR/WBP

-

Core:

-

Poplar Pine Hardwood Combi

-

MOQ:

-

1*20GP

-

Surface Treatment:

-

Matt High Glossy UV Coated

-

PAYMENT:

-

30% Deposit + 70% Balance

-

Delivery time:

-

Within 15 Days Receiving Deposit

Product Description

|

ITEM

|

PARTICLE BOARD

CHIPBOARD

|

|

MATERIAL

|

Pine,Poplar,Hardwood,recycling wood

|

|

GLUE

|

E0,E1

WBP,MR

|

|

DENSITY

|

650kg/cbm

|

|

SIZE

|

1220*2440/2750mm or as your request

|

|

THCIKNESS

|

4.75mm to 44mm

|

|

Thickness tolerance

|

+/-0.2mm (thickness<6mm),

+/-0.3~0.5mm (thickness≥6mm)

|

|

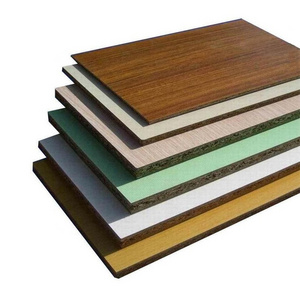

Surface treatment

|

Melamine/UV/Wood veneer/Sanded

|

|

Moisture Content

|

8%~14%

|

|

Place of Origin

|

China

|

|

MOQ

|

1*40GP

|

|

Grade

|

FIRST-CLASS

|

|

Supply Ability

|

3000cbm/month

|

|

Customized

|

Acceptable

|

Details Images

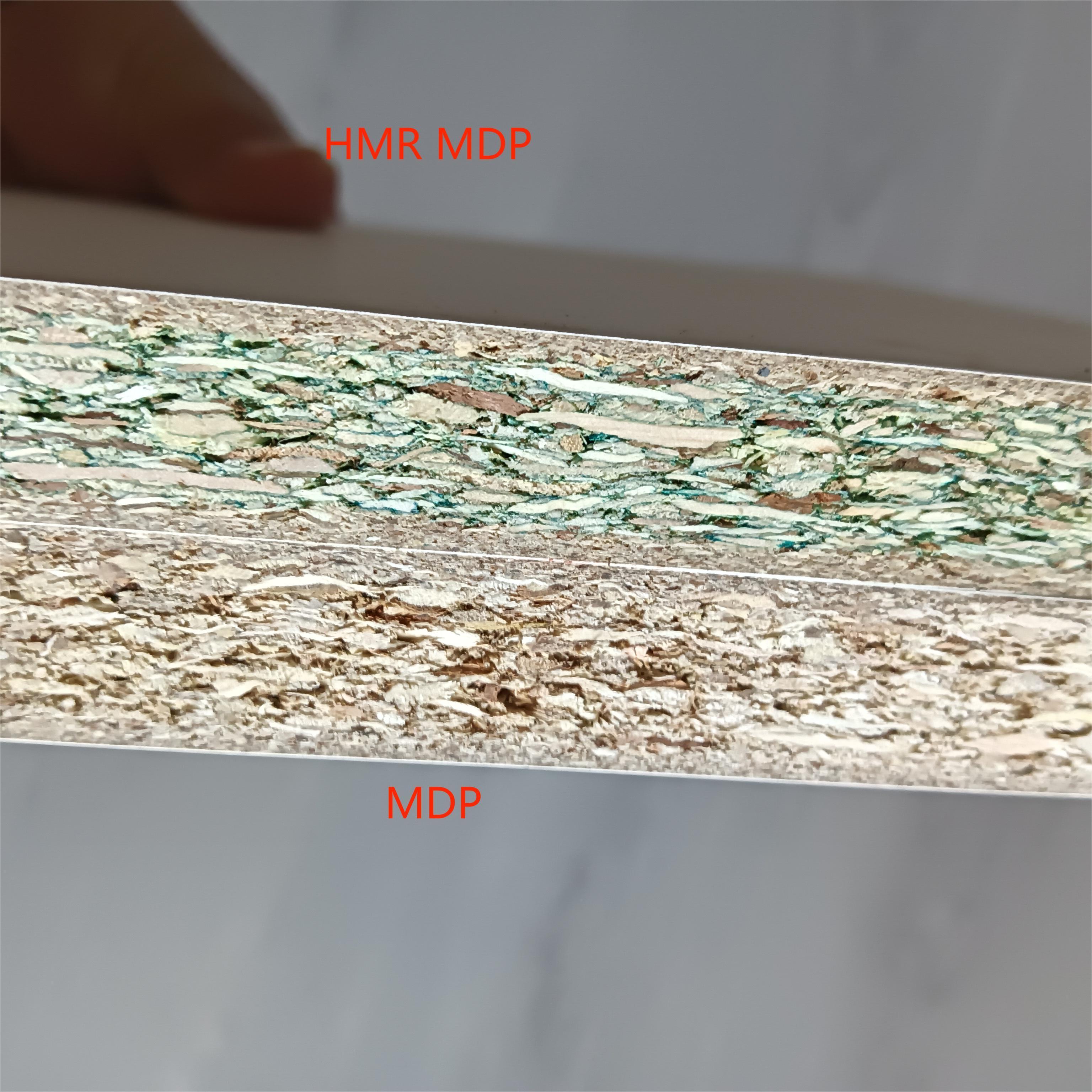

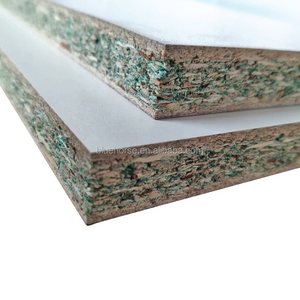

Particle board/OSB/LSB

particle board is a waste-wood product made by heat pressing wood chips, sawmill shavings, or even sawdust and resin together. To make the end product water resistant, fireproof, and/or insect-proof chemicals are used including wax, dyes, wetting agents, and release agents. After the resin, chemicals, and wood scraps have been mixed together, the liquid mixture is made into a sheet.

Weight

The weight of the wood chips is evenly distributed to make sure the finished board is not top heavy.

Structure

Compression is applied to the particle board sheet multiple times to create the tightest possible bond between the resin and the wood bits.

Application

Hot Searches