- Product Details

- {{item.text}}

Quick Details

-

CaO Content (%):

-

International standard

-

CrO Content (%):

-

International standard

-

SiC Content (%):

-

International standard

-

Place of Origin:

-

Henan, China

-

Model Number:

-

Acid Proof Brick

-

Brand Name:

-

Lite

-

Product name:

-

Firm in structure high alumina fire clay brick for sale

-

Fe2O3 %:

-

2%~2.5%

-

Refractoriness:

-

≥1770°C

-

Apparent porosity:

-

20-23

-

Bulk density (g/cm3):

-

2.1-2.6

-

Cold crushing strength (Mpa):

-

≥40

-

Refractoriness under load(0.2MPa):

-

≥1420°C

-

Reheating Linear Change (1500°C, 2h) %:

-

+0.1~ -0.4

-

Sample:

-

free

-

Name:

-

Firm in structure high alumina fire clay brick for sale

Quick Details

-

SiO2 Content (%):

-

International standard

-

Al2O3 Content (%):

-

55%~80%

-

MgO Content (%):

-

International standard

-

CaO Content (%):

-

International standard

-

CrO Content (%):

-

International standard

-

SiC Content (%):

-

International standard

-

Place of Origin:

-

Henan, China

-

Model Number:

-

Acid Proof Brick

-

Brand Name:

-

Lite

-

Product name:

-

Firm in structure high alumina fire clay brick for sale

-

Fe2O3 %:

-

2%~2.5%

-

Refractoriness:

-

≥1770°C

-

Apparent porosity:

-

20-23

-

Bulk density (g/cm3):

-

2.1-2.6

-

Cold crushing strength (Mpa):

-

≥40

-

Refractoriness under load(0.2MPa):

-

≥1420°C

-

Reheating Linear Change (1500°C, 2h) %:

-

+0.1~ -0.4

-

Sample:

-

free

-

Name:

-

Firm in structure high alumina fire clay brick for sale

refractory acid proof fire acid resistant ceramic brick for chimney

Acid proof brick is made of high quality high silica acid resistance material, which can effectively resist to the corrosion of high sulfur gas , widely used in electric power, petrifaction, chimneys of metallurgy and other thermal equipment, and the liners of flue and easy-corrosive liners.

|

Index |

Special acid-proof brick |

Lightweight acid-proof brick |

|

SiO2(%) ≥ |

65 |

65 |

|

Bulk Density(g/m³) |

1.6-1.8 |

1.0-1.3 |

|

Cold Crushing Strength(Mpa) ≥ |

15 |

10 |

|

Thermal Conductivity(W/m.k) ≤ |

0.65 |

0.45 |

|

Water Absorption(%) ≤ |

15 |

working face 5 |

|

Acid-proof rate(%) ≤ |

98 |

97 |

|

Service temperature( ℃) ≤ |

1000 |

1000 |

Common sizes

|

Straight type |

Arch type |

Wedge type |

|

L×W×H (mm) 230×114×65 230×114×75 230×114×32 220×110×60 220×110×50 220×110×40 220×110×30 |

L×W×H/h (mm) 230×114×65/55 230×114×65/45 230×114×65/59 220×110×65/50 220×110×75/65 220×110×60/40 |

L×W×H/h (mm) 230×114×65/55 230×114×65/45 220×110×75/65 220×110×60/40 |

|

Other sizes according to customer requirements. |

||

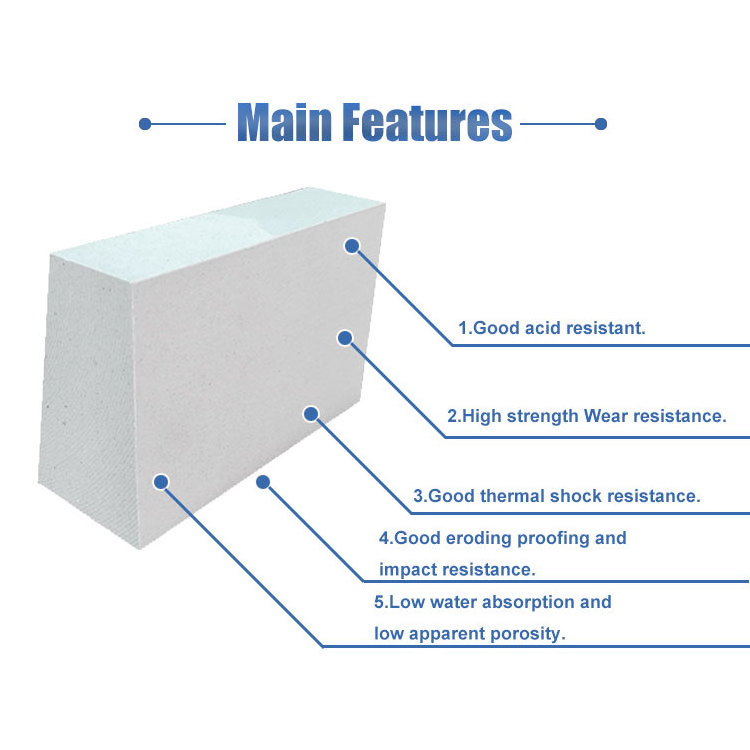

Features

1. Good acid resistant.

2. High strength and Wear resistance.

3. Low water absorption and low apparent porosity.

4. Good eroding proofing and impact resistance.

5. High temperature resistant.

6.Good thermal shock resistance.

7. High mechanical strength.

Application

The acid proof brick can be widely applied to the lining construction of tower, pool, tank, groove of the petroleum, chemical industry, chemical fertilizer, pharmacy, brewing, dairy product, paper making, smelt, chemical fiber and electroplating, chemical laboratory, electricity generation, gas and other industry.

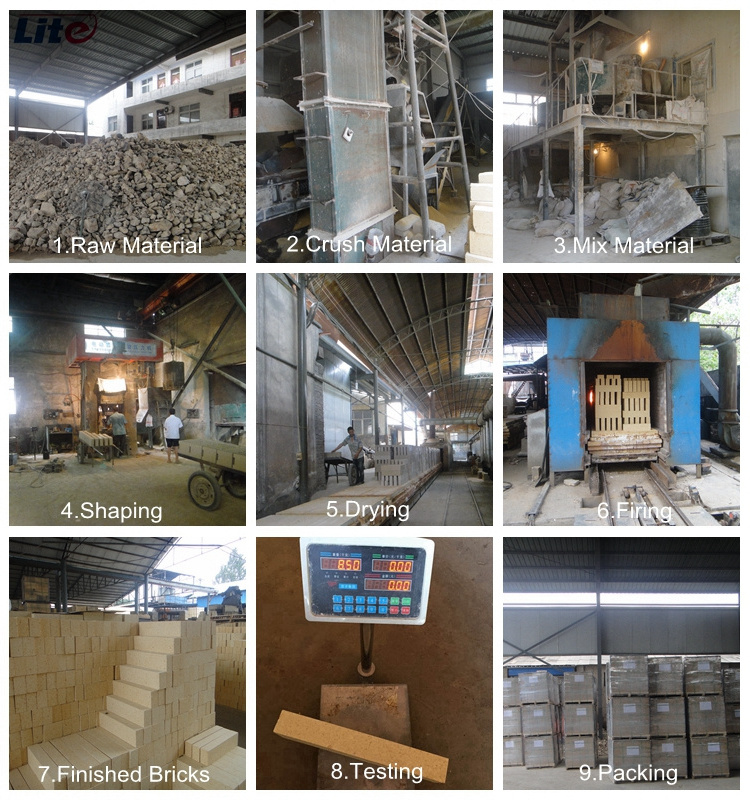

1.Production Process

Crushing→Mixing→Shaping→Drying→Firing→Inspection→Packaging and Shipment

2.Quality Assurance

Lite Refractory is committed to high quality standards for all its products and services. With its thirst on State of the art technology at every level and a wide range of products, Lite Refractory can provide ideal solutions for the stringent requirement of the customer. Backed by decade of experience in different industries, and close association with customers,Lite Refractory will always bring new products which will give better life and value to the user.

The quality assurance system consists of the following steps:

a.Inspection and Control of incoming raw materials :According to the chemical content,raw materials are classified into different levels to ensure quality of brick first.

b.Inspection and control of the process: During the production,every brick will be weighed twice strictly to reduce the error of weight .

c.Inspection of product Standardization of quality of each product by process control and experimentation.

d.Taking corrective measures whenever deviations are noted.

e.Quality audit by quality management .Before delivery, the inspectors will inspect the size,appearance,physical and chemical properties of brick again in factory.

Package Informations:

1.On wooden pallets with plastic cover ,

2.According to customer's requirements.

(1)Wooden pallet size:1000*1000mm,Load weight of each pallet:1.5-2.0 Tons .

(2)20 Foot Container can be loaded 25Tons,40 Foot Container can be loaded 28Tons .

1. FEDEX/DHL/UPS/TNT for samples.

2. By Sea for batch goods .

3. Customers specifying freight forwarders or negotiable shipping methods!

4. Delivery Time: 3 days for common shape samples;15 days for special shape samples.Within 30 days for batch goods.

1. Payment: T/T, Western Union,LC; Usually 30% deposits,70% balance before delivery or negotiations to solve.

2. MOQ: Usually 1Tons, Customers can order certain PCS for special brick.

3. Quality Warranty: 1 years ,