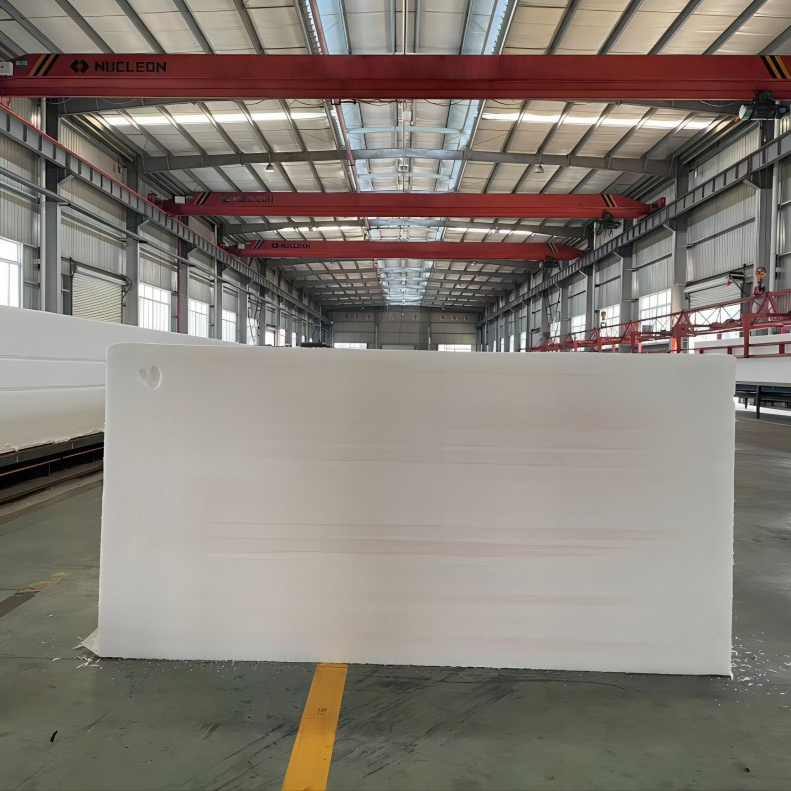

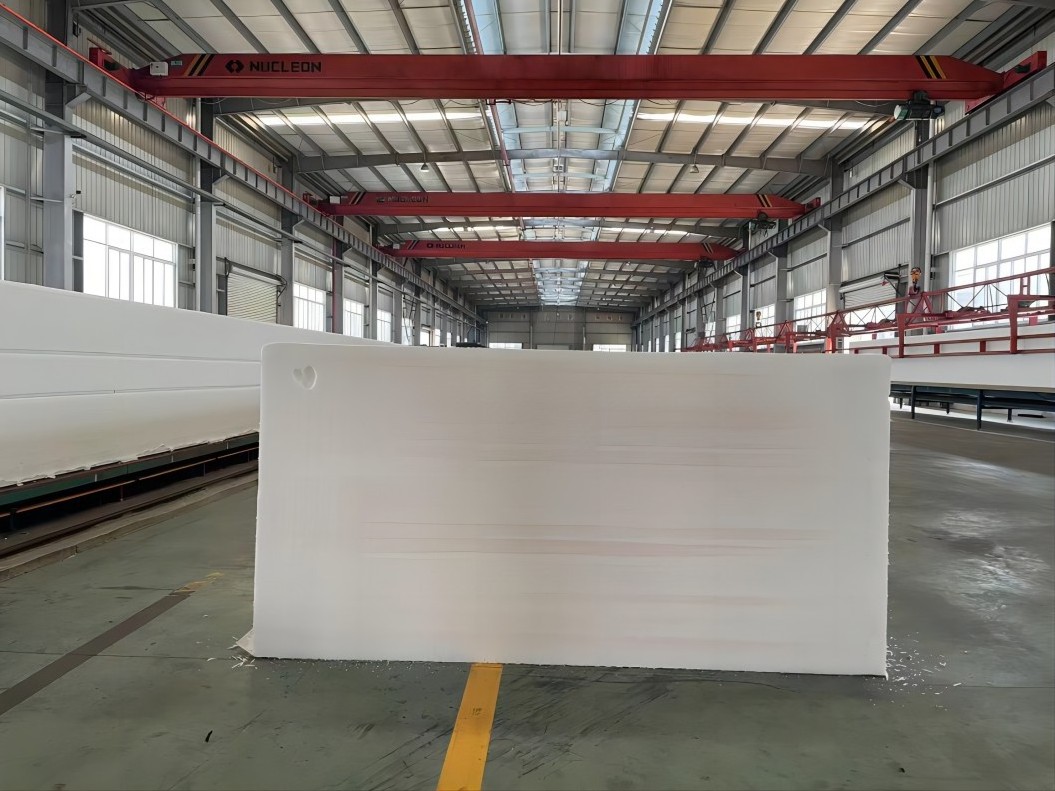

Big &Small Material Tank

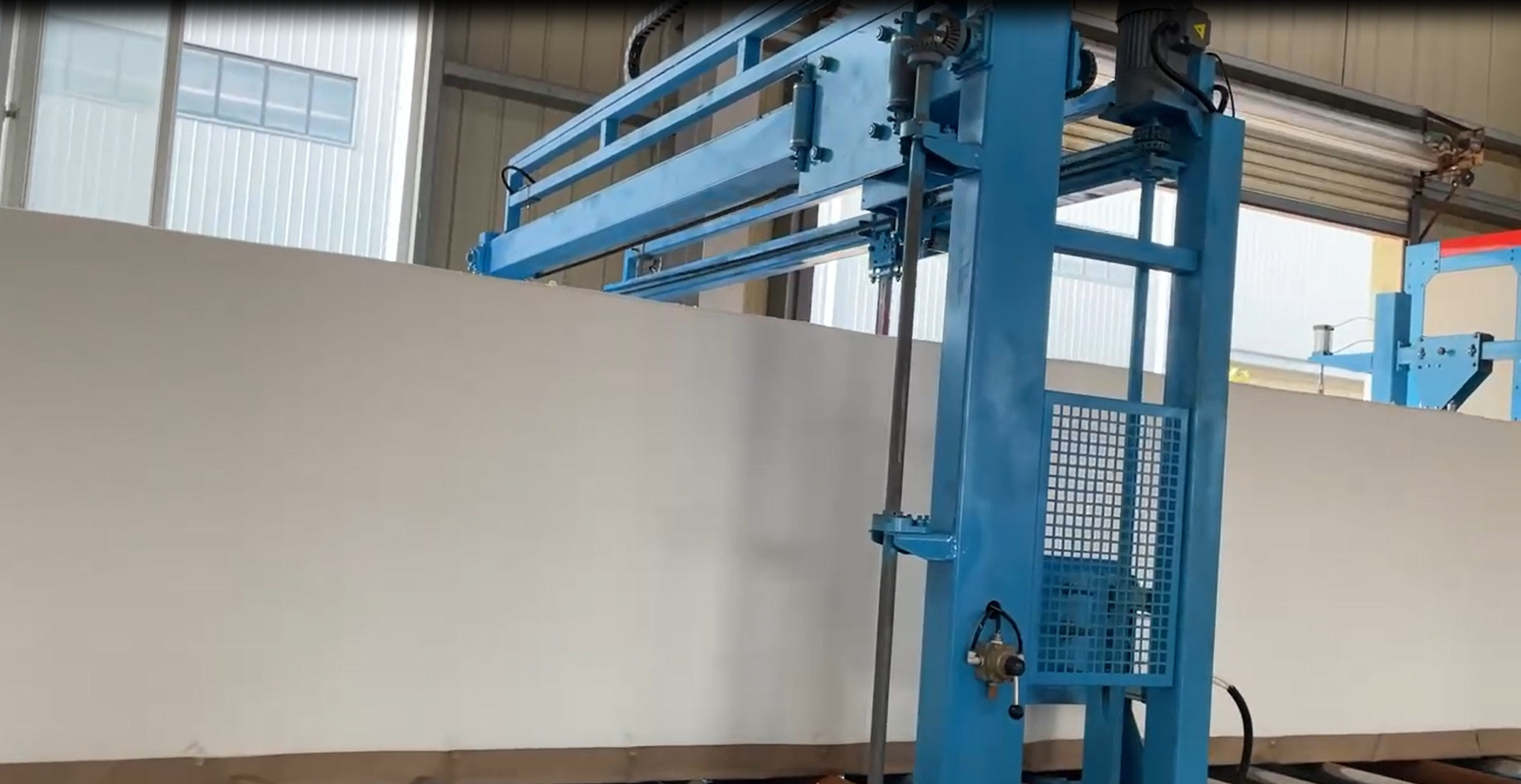

1. 13 components

2.

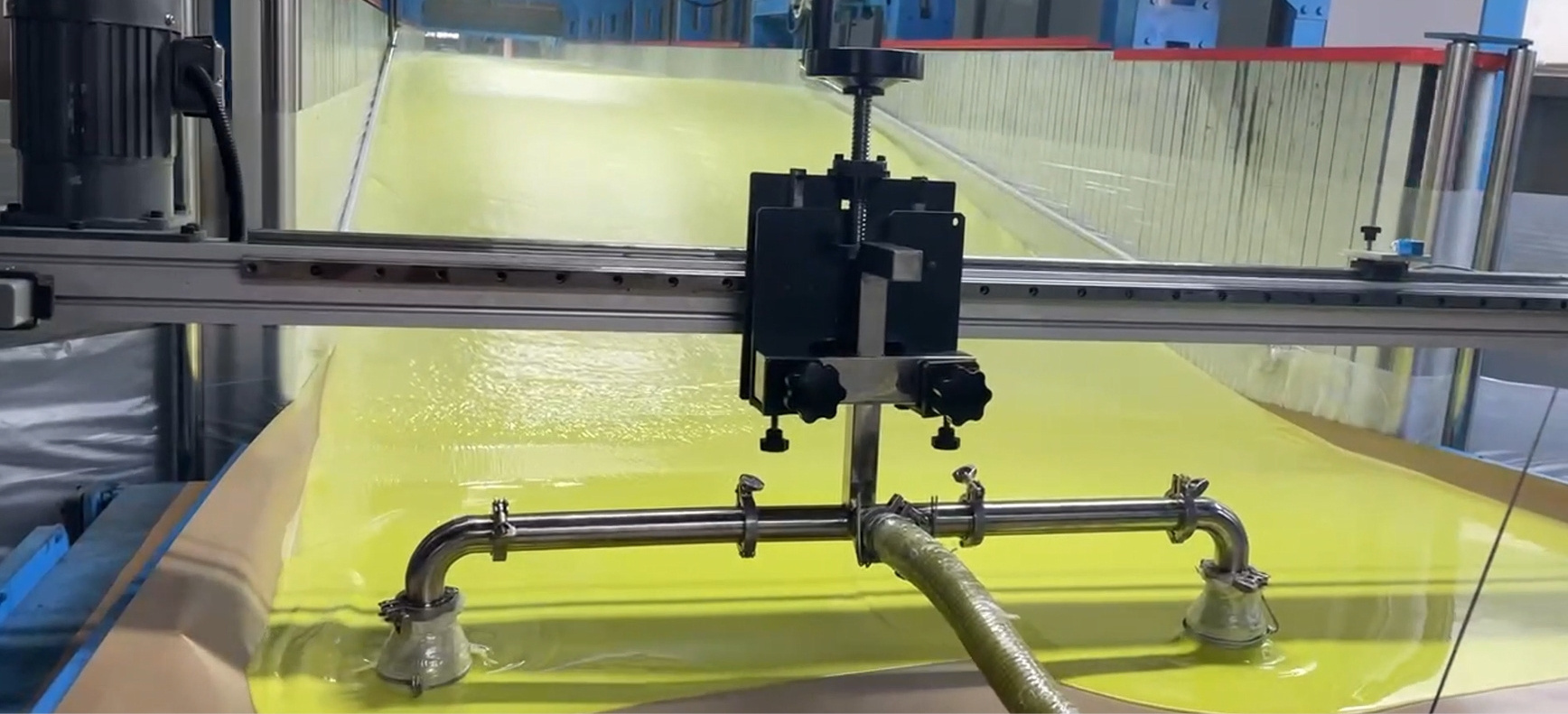

Automatic temperature control system

3.

Magnetic coupling structure, never leakage, double-stage high-pressure pump, more Accurate and durable